Pressure Cap

1

2

3

|

| |

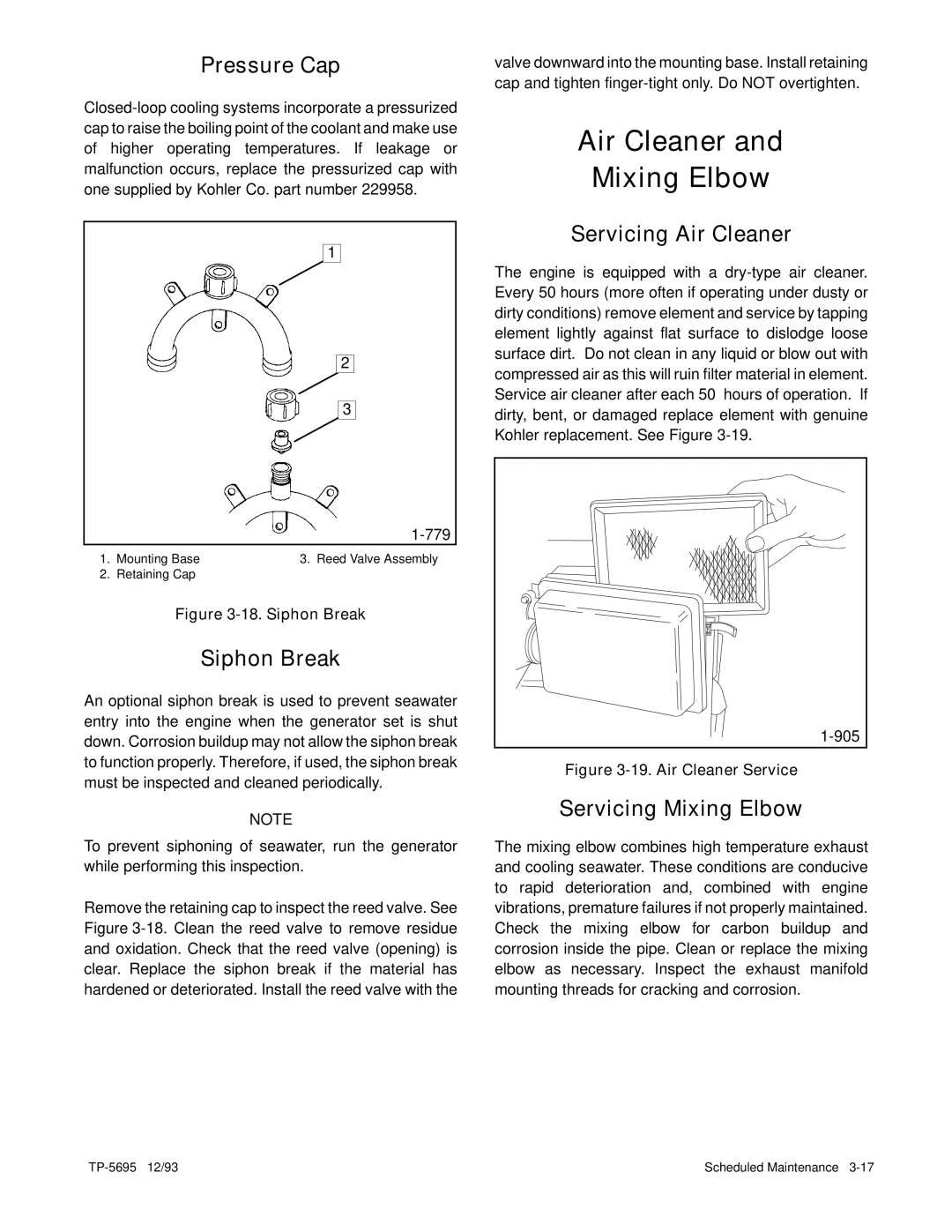

1. | Mounting Base | 3. Reed Valve Assembly |

2. | Retaining Cap |

|

Figure 3-18. Siphon Break

Siphon Break

An optional siphon break is used to prevent seawater entry into the engine when the generator set is shut down. Corrosion buildup may not allow the siphon break to function properly. Therefore, if used, the siphon break must be inspected and cleaned periodically.

NOTE

To prevent siphoning of seawater, run the generator while performing this inspection.

Remove the retaining cap to inspect the reed valve. See Figure

valve downward into the mounting base. Install retaining cap and tighten

Air Cleaner and

Mixing Elbow

Servicing Air Cleaner

The engine is equipped with a

Figure 3-19. Air Cleaner Service

Servicing Mixing Elbow

The mixing elbow combines high temperature exhaust and cooling seawater. These conditions are conducive to rapid deterioration and, combined with engine vibrations, premature failures if not properly maintained. Check the mixing elbow for carbon buildup and corrosion inside the pipe. Clean or replace the mixing elbow as necessary. Inspect the exhaust manifold mounting threads for cracking and corrosion.

| Scheduled Maintenance |