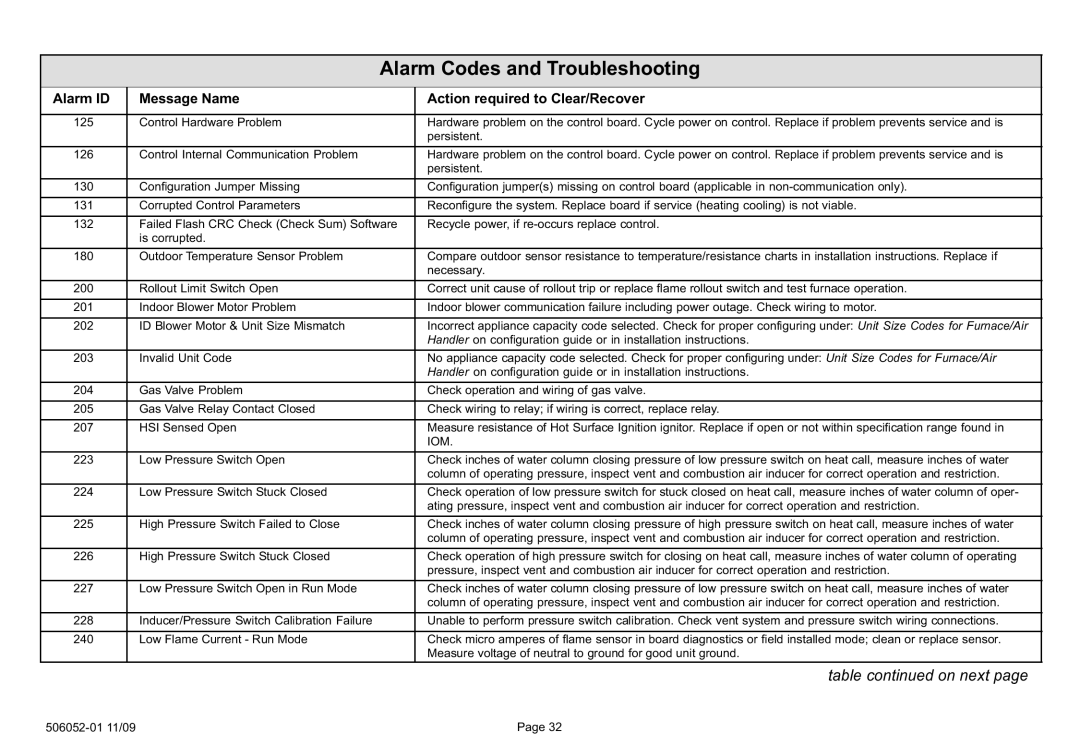

| Alarm Codes and Troubleshooting | |

|

|

|

Alarm ID | Message Name | Action required to Clear/Recover |

|

|

|

125 | Control Hardware Problem | Hardware problem on the control board. Cycle power on control. Replace if problem prevents service and is |

|

| persistent. |

|

|

|

126 | Control Internal Communication Problem | Hardware problem on the control board. Cycle power on control. Replace if problem prevents service and is |

|

| persistent. |

|

|

|

130 | Configuration Jumper Missing | Configuration jumper(s) missing on control board (applicable in non−communication only). |

|

|

|

131 | Corrupted Control Parameters | Reconfigure the system. Replace board if service (heating cooling) is not viable. |

|

|

|

132 | Failed Flash CRC Check (Check Sum) Software | Recycle power, if re−occurs replace control. |

| is corrupted. |

|

|

|

|

180 | Outdoor Temperature Sensor Problem | Compare outdoor sensor resistance to temperature/resistance charts in installation instructions. Replace if |

|

| necessary. |

|

|

|

200 | Rollout Limit Switch Open | Correct unit cause of rollout trip or replace flame rollout switch and test furnace operation. |

|

|

|

201 | Indoor Blower Motor Problem | Indoor blower communication failure including power outage. Check wiring to motor. |

|

|

|

202 | ID Blower Motor & Unit Size Mismatch | Incorrect appliance capacity code selected. Check for proper configuring under: Unit Size Codes for Furnace/Air |

|

| Handler on configuration guide or in installation instructions. |

|

|

|

203 | Invalid Unit Code | No appliance capacity code selected. Check for proper configuring under: Unit Size Codes for Furnace/Air |

|

| Handler on configuration guide or in installation instructions. |

|

|

|

204 | Gas Valve Problem | Check operation and wiring of gas valve. |

|

|

|

205 | Gas Valve Relay Contact Closed | Check wiring to relay; if wiring is correct, replace relay. |

|

|

|

207 | HSI Sensed Open | Measure resistance of Hot Surface Ignition ignitor. Replace if open or not within specification range found in |

|

| IOM. |

|

|

|

223 | Low Pressure Switch Open | Check inches of water column closing pressure of low pressure switch on heat call, measure inches of water |

|

| column of operating pressure, inspect vent and combustion air inducer for correct operation and restriction. |

|

|

|

224 | Low Pressure Switch Stuck Closed | Check operation of low pressure switch for stuck closed on heat call, measure inches of water column of oper- |

|

| ating pressure, inspect vent and combustion air inducer for correct operation and restriction. |

|

|

|

225 | High Pressure Switch Failed to Close | Check inches of water column closing pressure of high pressure switch on heat call, measure inches of water |

|

| column of operating pressure, inspect vent and combustion air inducer for correct operation and restriction. |

|

|

|

226 | High Pressure Switch Stuck Closed | Check operation of high pressure switch for closing on heat call, measure inches of water column of operating |

|

| pressure, inspect vent and combustion air inducer for correct operation and restriction. |

|

|

|

227 | Low Pressure Switch Open in Run Mode | Check inches of water column closing pressure of low pressure switch on heat call, measure inches of water |

|

| column of operating pressure, inspect vent and combustion air inducer for correct operation and restriction. |

|

|

|

228 | Inducer/Pressure Switch Calibration Failure | Unable to perform pressure switch calibration. Check vent system and pressure switch wiring connections. |

|

|

|

240 | Low Flame Current − Run Mode | Check micro amperes of flame sensor in board diagnostics or field installed mode; clean or replace sensor. |

|

| Measure voltage of neutral to ground for good unit ground. |

|

| table continued on next page |

506052−01 11/09 | Page 32 |