GENERAL SAFETY GUIDELINES

! WARNING

Risk of electric shock. Can cause injury or death.

Disconnect local and remote power supplies before working within.

Before proceeding with installation of the XDP, read all instructions, verify that all the parts are included and check the nameplate to be sure the XDP voltage matches the available utility power.

Follow all applicable codes.

! WARNING

Risk of unit falling over. Can cause death, injury or property damage. The XDP is

NOTE

This document is intended to be be used together with site specific documentation and documentation for other parts of the system (heat rejection devices and cooling modules).

NOTE

Before any action that could cause a disturbance in the XD system’s cooling function is begun, the facility manager MUST be informed. In addition, after the action is taken and the work is finished, the facility manager MUST be informed.

NOTICE

Risk of piping and component rupture. May cause injury or equipment damage.

Do not close service valves without following recommended procedures for repair, maintenance and replacement of components. Closing service valves may isolate liquid refrigerant, causing high pressure and rupture of piping. Install pressure relief valves in field piping that may become isolated by service valves.

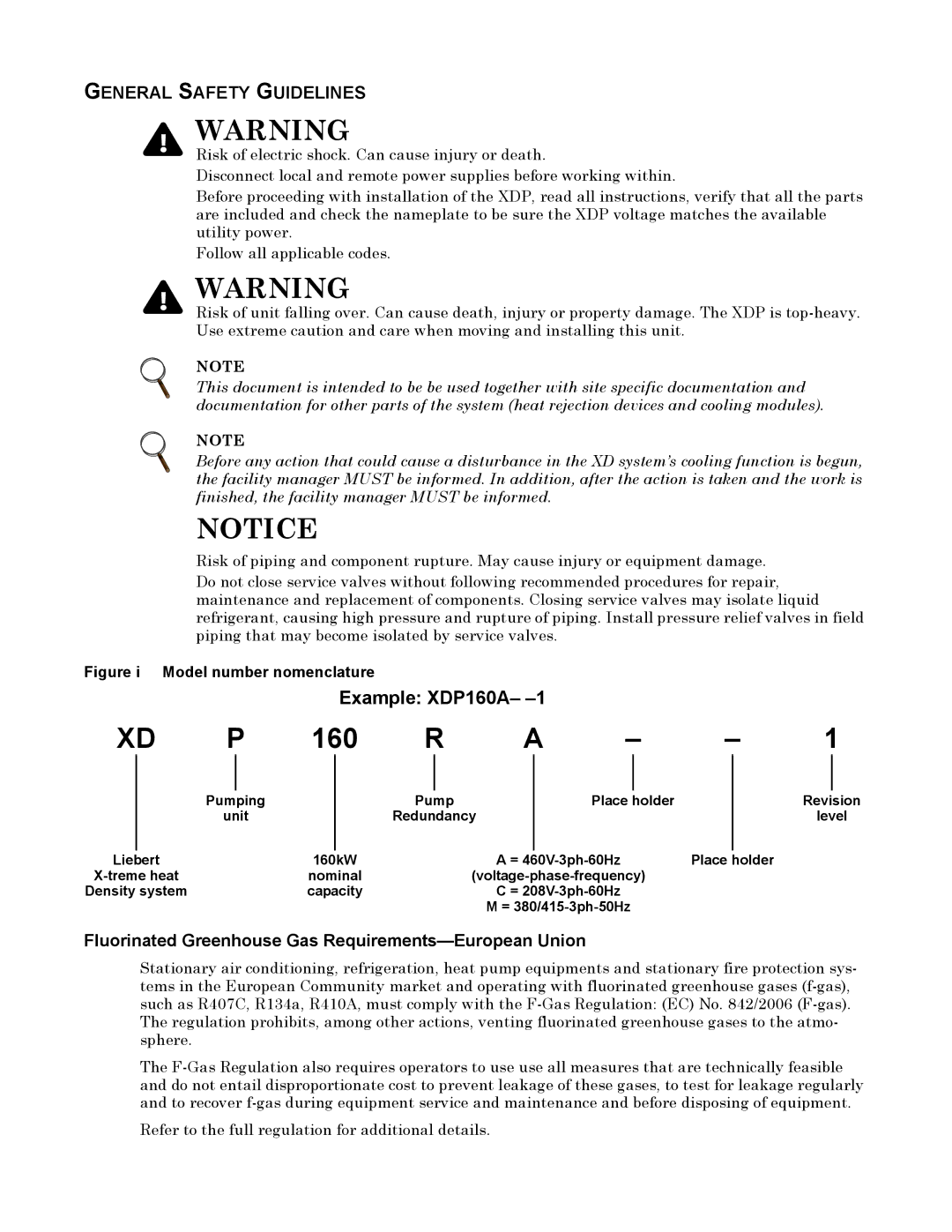

Figure i Model number nomenclature

|

|

|

|

| Example: XDP160A– |

|

|

|

|

|

| ||||

XD | P | 160 | R | A | – | – | 1 | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| Pumping |

|

| Pump |

| Place holder |

|

| Revision | |||||

|

| unit |

|

| Redundancy |

|

|

|

|

|

| level | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Liebert |

|

| 160kW |

|

| A = |

|

| Place holder |

|

| ||||

|

| nominal |

|

|

|

|

| ||||||||

Density system |

|

| capacity |

|

| C = |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| M = |

|

|

|

| |||

Fluorinated Greenhouse Gas Requirements—European Union

Stationary air conditioning, refrigeration, heat pump equipments and stationary fire protection sys- tems in the European Community market and operating with fluorinated greenhouse gases

The

Refer to the full regulation for additional details.