Return to Section TOC

Return to Master TOC

| TROUBLESHOOTING | |||

|

|

|

| |

|

|

|

|

|

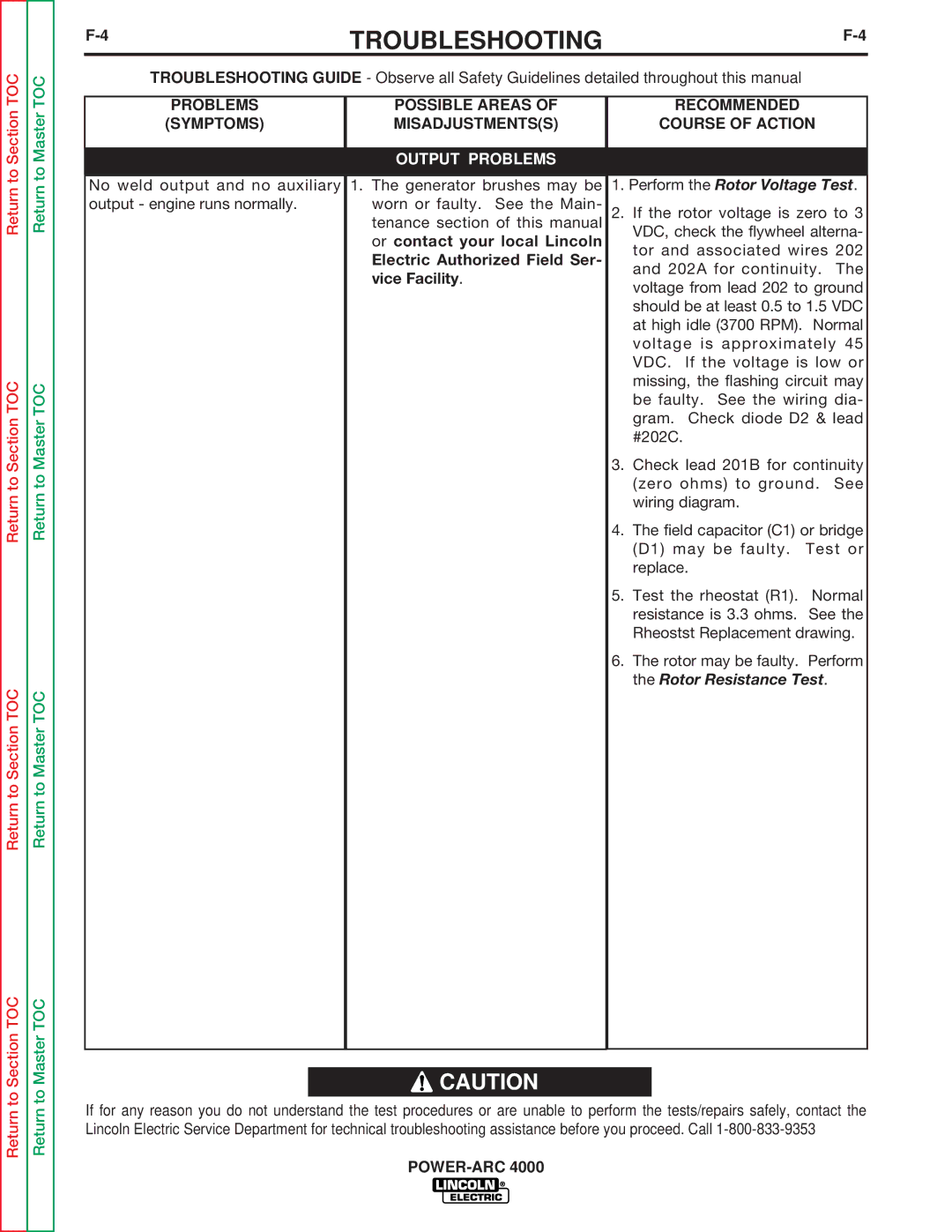

| TROUBLESHOOTING GUIDE - Observe all Safety Guidelines detailed throughout this manual | |||

|

|

|

|

|

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

|

| (SYMPTOMS) | MISADJUSTMENTS(S) | COURSE OF ACTION |

|

|

|

|

|

|

OUTPUT PROBLEMS

No weld output and no auxiliary 1. The generator brushes may be 1. Perform the Rotor Voltage Test.

output - engine runs normally. worn or faulty. See the Main- 2. If the rotor voltage is zero to 3 tenance section of this manual

or contact your local Lincoln

VDC, check the flywheel alterna- tor and associated wires 202

Electric Authorized Field Ser-

Section TOC

Master TOC

vice Facility.

and 202A for continuity. The voltage from lead 202 to ground should be at least 0.5 to 1.5 VDC at high idle (3700 RPM). Normal voltage is approximately 45 VDC. If the voltage is low or missing, the flashing circuit may be faulty. See the wiring dia- gram. Check diode D2 & lead #202C.

Return to

Return to Section TOC

Return to Section TOC

Return to

Return to Master TOC

Return to Master TOC

3. Check lead 201B for continuity (zero ohms) to ground. See wiring diagram.

4. The field capacitor (C1) or bridge

(D1) may be faulty. Test or replace.

5. Test the rheostat (R1). Normal resistance is 3.3 ohms. See the Rheostst Replacement drawing.

6. The rotor may be faulty. Perform the Rotor Resistance Test.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call