Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

THEORY OF OPERATION

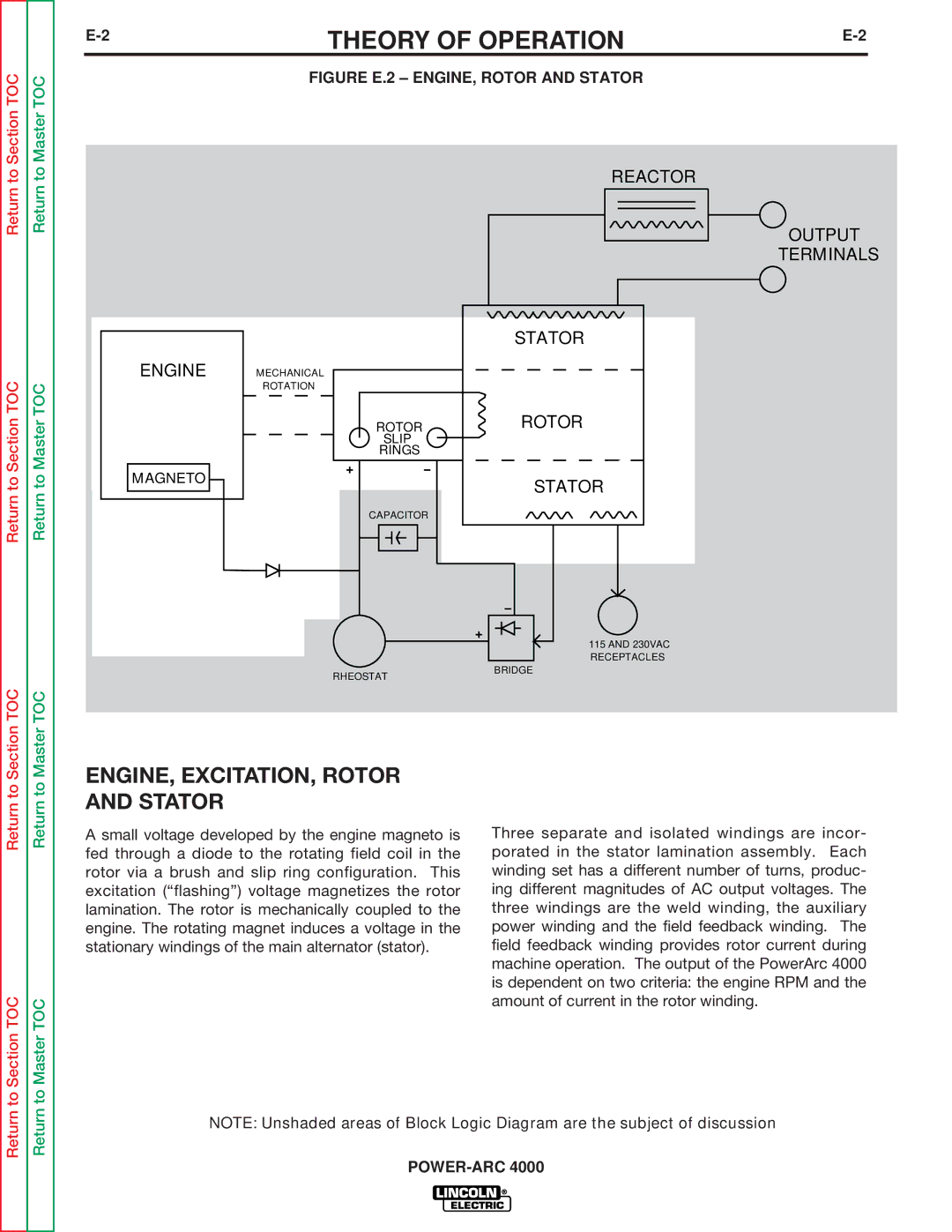

FIGURE E.2 – ENGINE, ROTOR AND STATOR

REACTOR

OUTPUT

TERMINALS

|

| STATOR |

ENGINE | MECHANICAL |

|

| ROTATION |

|

| ROTOR | ROTOR |

| SLIP |

|

| RINGS |

|

MAGNETO |

| STATOR |

|

| |

| CAPACITOR |

|

RHEOSTAT

115 AND 230VAC

RECEPTACLES

BRIDGE

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

ENGINE, EXCITATION, ROTOR AND STATOR

A small voltage developed by the engine magneto is fed through a diode to the rotating field coil in the rotor via a brush and slip ring configuration. This excitation (“flashing”) voltage magnetizes the rotor lamination. The rotor is mechanically coupled to the engine. The rotating magnet induces a voltage in the stationary windings of the main alternator (stator).

Three separate and isolated windings are incor- porated in the stator lamination assembly. Each winding set has a different number of turns, produc- ing different magnitudes of AC output voltages. The three windings are the weld winding, the auxiliary power winding and the field feedback winding. The field feedback winding provides rotor current during machine operation. The output of the PowerArc 4000 is dependent on two criteria: the engine RPM and the amount of current in the rotor winding.

Return

Return

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion