Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR | ||

|

| |

|

|

|

CAPACITOR AND/OR DIODE BRIDGE REMOVAL AND REPLACEMENT

(continued)

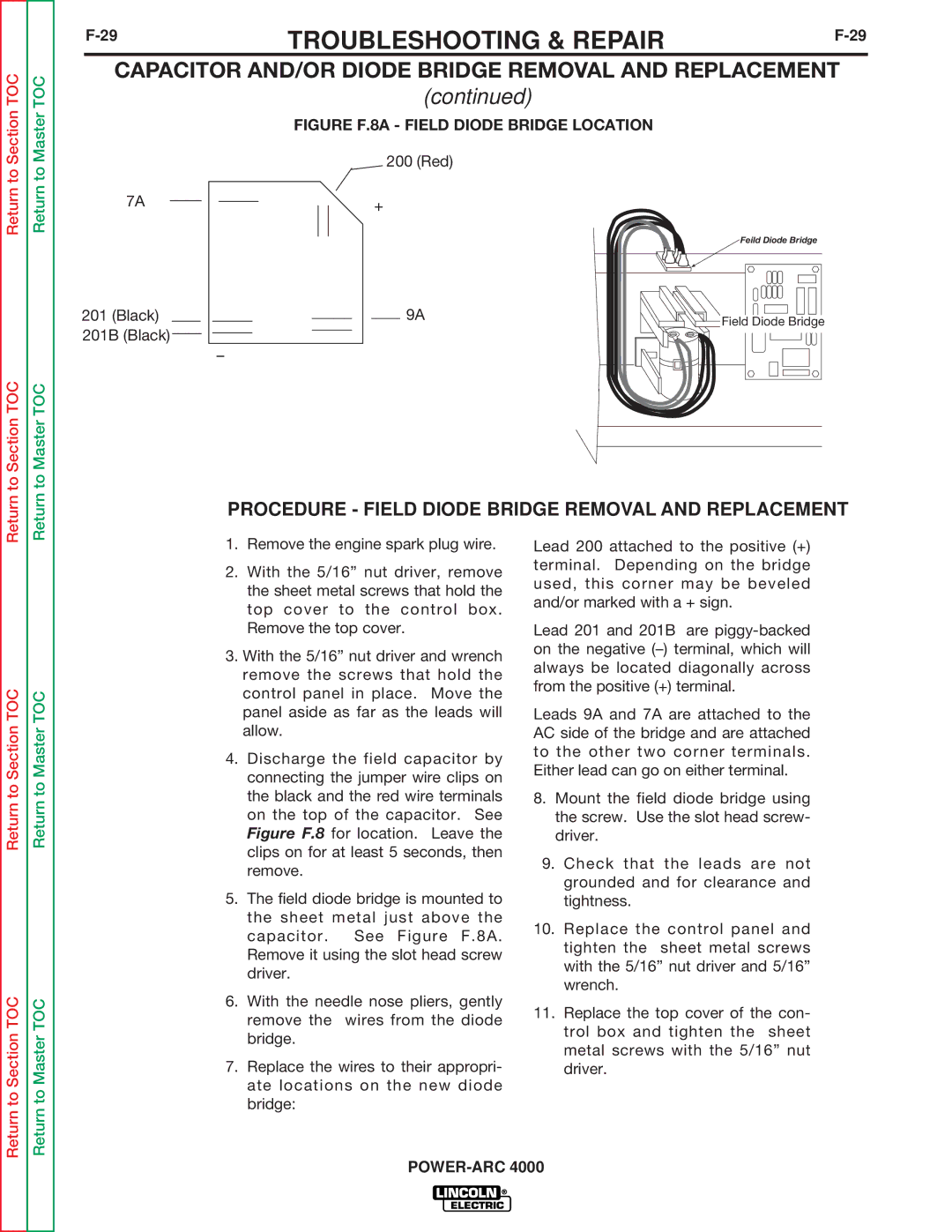

FIGURE F.8A - FIELD DIODE BRIDGE LOCATION

200 (Red)

7A | + |

|

Feild Diode Bridge

201 (Black) | 9A | Field Diode Bridge |

201B (Black) |

| |

|

| |

| – |

|

PROCEDURE - FIELD DIODE BRIDGE REMOVAL AND REPLACEMENT

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

1.Remove the engine spark plug wire.

2.With the 5/16” nut driver, remove the sheet metal screws that hold the top cover to the control box. Remove the top cover.

3.With the 5/16” nut driver and wrench remove the screws that hold the control panel in place. Move the panel aside as far as the leads will allow.

4.Discharge the field capacitor by connecting the jumper wire clips on the black and the red wire terminals on the top of the capacitor. See Figure F.8 for location. Leave the clips on for at least 5 seconds, then remove.

5.The field diode bridge is mounted to the sheet metal just above the capacitor. See Figure F.8A. Remove it using the slot head screw driver.

6.With the needle nose pliers, gently remove the wires from the diode bridge.

7.Replace the wires to their appropri- ate locations on the new diode bridge:

Lead 200 attached to the positive (+) terminal. Depending on the bridge used, this corner may be beveled and/or marked with a + sign.

Lead 201 and 201B are

Leads 9A and 7A are attached to the AC side of the bridge and are attached to the other two corner terminals. Either lead can go on either terminal.

8.Mount the field diode bridge using the screw. Use the slot head screw- driver.

9.Check that the leads are not grounded and for clearance and tightness.

10.Replace the control panel and tighten the sheet metal screws with the 5/16” nut driver and 5/16” wrench.

11.Replace the top cover of the con- trol box and tighten the sheet metal screws with the 5/16” nut driver.