CF-Y5

For U.K This apparatus must be earthed for your safety

How to replace the fuse

Laser Safety Information

Page

Page

Contents

„ Main Specifications

Specifications

Secondary cache memory

Bluetooth

Wireless LAN

Useful Information Getting Started

Names and Functions of Parts

Battery Latches Battery Pack Emergency Hole RAM Module Slot

SD Memory Card Slot Bluetooth Antenna

DC-IN Jack Ventilation Hole External Display Port

Headphone Jack

Yonah LV Dual Core

Block Diagram

Diagnosis Procedure

Flow Chart

Troubleshooting

Error Diagnosis by Checking Beep Signal Sound

Power-On Self Test Boot Check

Outline of Post

Diagnosis

Stuck key

02D0 System cache error Cache disabled

When you execute the enhancing test

When you execute an automatic test

Self Diagnosis Test

Shift and left Shift keys

Operation of PC-Diagnostic Utility

Content of the setup is returned to the setting of the user

PC-Diagnostic utility End method

Selection of tested device

Place with possibili

Enhancing

Standard Enhanced

Cable characteristic and device

Breakdown. e.g.. Head, Motor

Memory as Vram may fail with

LCD

Wiring Connection Diagram

Disassembly instructions

Preparation

Before disassembly, be sure to perform the following steps

Removing the HDD

Removing the Keyboard

Preparation perform the .2.1., 9.2.3. first

Removing the Top Case

Preparation perform the .2.1., 9.2.3. and 9.2.4. first

Removing the SUB DVD

Ffcpadffcsw

SUB DVD

Removing the Solenoid / Disc Cover Lock

Removing the Touch Pad / LCD Knob

Pad WP Sheet LCD Knob LCD Latch Spring Top Case

Top Case Screw Q Solenoid Line Hold Sheet Cable Fixed Sheet

Removing the FAN

Removing the Speaker L, R

Preparation perform the .2.1 9.2.4. first

FAN

Removing the Main Board

Removing the Drive Unit

Gadket

Removing the Antenna Board Unit L, R

Removing the DC-IN Cable

USB FPC

Preparation perform the .2.1 9.2.11. first

Removing the Modem

Modem

Removing the Hinge Cover L, R

Removing the LCD Unit

Removing the LCD Unit and the LCD Rear

Preparation perform the .2.1 9.2.18. first

CN2

Removing the LCD Cable / Inverter Board

Assembly of the LCD Front

Assembly knowhow of the LCD

Putting LCD Side Cushion / LCD Tape

2mm Hinge Side 1mm Hook Side LCD Side Cushion

LCD

Putting LCD Side Rubber / LCD Side Damper

Side Rubber

Rib Rib standard

Putting LCD Magnet

Putting LCD Cushion / Assembly of the Inverter

Preparation for Inverter Case

Putting Tape for LCD Cable

Order

Externals match

Page

Page

Putting Line Hold Sheet / Antenna Sheet / BT PWB Cushion

Assembly knowhow of the Main Board

Putting MCH Sheet / Heat Spreader Bottom

Assembly of the Main Board

Assembly of the Wlan Sheet / MCH Thermal Tape

HDD FPC

Right before building Left before building Square hole

Assembly of the Card Bus Ejector

Safety work

Assembly of the Wireless LAN Module / Modem

DXQT2+E6FNL

Insert the Main Board

DXQT2+D25FNL

Assembly of the Disk Cover

Assembly knowhow of the Top Case

Lan Sw Blank Installation

Assembly of the Top Case

Putting Disk Angle Cushion

LAN on /OFF

Top Case Rib

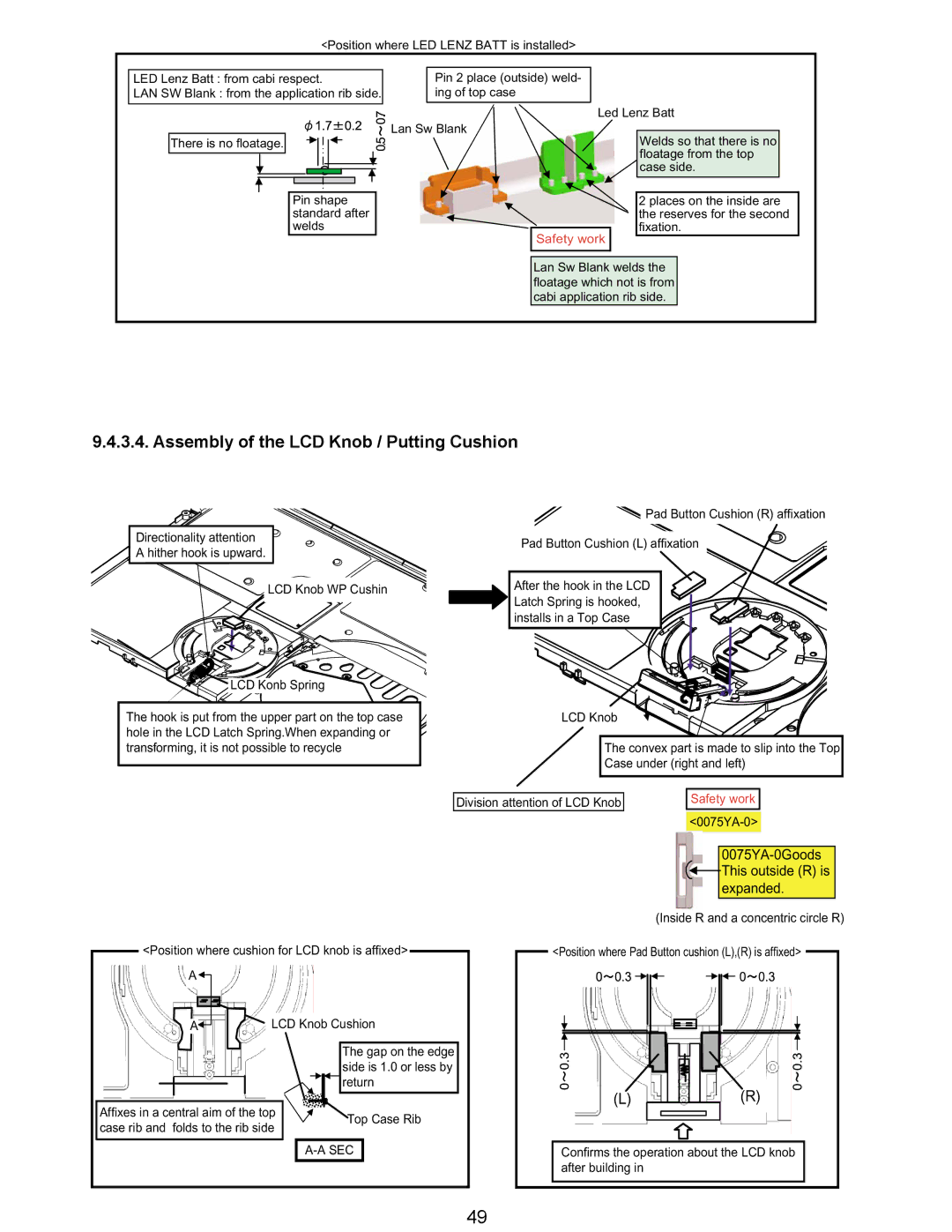

Assembly of the LCD Knob / Putting Cushion

Case rib and folds to the rib side

SEC

Pad Cover Externals

Assembly of the Touch Pad

Install the Pad Cover

Safety work

Pad Cover installation position

Fixation seat

Putting Sheet

Affixes Disk cover cushion

Cushion

Assembly of the Break Lever

Axis nor the shuttlecock

Assembly of the FAN

Conclusion

Assembly of the Disk Cover Lock / SW PCB

Assembly of the Disk Cover Click

Engagement fingernail is

Confirmation two places as

SW PCB

SW PCB yellow line Screw DXHM0056ZA Yellow line

Affixation Disk Lever Fix Cushion

Possible to recycle

Assembly of the Speaker

Assembly of the Solenoid

Wiring Speaker Cable

Difference line

Putting Cushion / Tape / Sheet

Assembly of the SW PCB FFC

Page

Assembly of the Dimm Cover

Assembly knowhow of the Bottom Case

Putting Line Hold Sheet

LED Lenz SD

Cutting lack part top side

Putting Foot Rubber

FIG1 Safety Work

Do not go out of the rib

Installation of Main Board

Assembly knowhow of the Body

Keyboard preparation

Main PWB Assy

FIG2

Assembly of the HDD Slot Guard

Back

Putting Line Hold Sheet 3 / Line Hold Cushion

Side without tape

Insert the Modem Cable in the slit

FFC

ANT PWB

Side with I-PEX stamp

Installation of LCD Unit

Cable in CN

Cable black Tape Externals

CPU

DFHE5035ZB

Affixes Gasket Cloth FIG1

Assembly of the DVD Drive

Assembly of the Body

Installation of Power Knob / LAN SW Knob

LAN ON/OFF

Top Case side screw tightening

Installation of K/B Heat Spreader

DXQT2+E6FNL DXQT2+F3FNL DXQT2+E10FNL DRQT2+E8FKL

Installation of Keyboard

Installation of Disk Cover / Disk Side Cover

How to detach Keyboard and K/B Side Cover

Installation of K/B Side Cover

Side Cover R

Side Cover L

Bottom Case side screw tightening

Installation of HDD

DFQT0046ZA

Putting Label

Screw tightening torque

Exploded View

K52 K145 K157

Cabinet Section

N7 Screw tightening torque

REF. no and Area

Replacement Parts List

DFHG1874YA LCD Cushion

DFMD1202ZA DC Jack Plate

DFHR3D21YA Line Hold Sheet

DXQT2+E6FNL Screw

EEFSX0D331ER

CF-Y5LWVYZBM 2006/11/16 REF. no and Area

EEFCX0D221R

EEFCX0J101R

Connector

EEFCX0G151R

EEFCD0D101ER

IC, USB Power SW

IC, Temperature Censor IC

Diode

DEDRB081L20 Diode

IC, Q-SWITCH

IC, FET Switch

IC, Audio Power Amplifier

IC, Power Management Switch

B1GBCFNN0042 Transistor

B1GFCFEN0003 Transistor

B1GBCFNL0017 Transistor

ERJ2GEJ102X RESISTOR, 1/16W, 1KΩ

ERJ2GEJ201X

ERJ2GEJ103X RESISTOR, 1/16W, 10KΩ

ERJ2GEJ100X

ERJ2GE0R00X RESISTOR, 1/16W, 0Ω

ERJ2RKF3922X

ERJ2GEJ105X RESISTOR, 1/16W, 1MΩ

ERJ2RKF2002X RESISTOR, 1/16W, 20KΩ

ERJ2GEJ472X

EVQPLDA15 Switch

Slide Switch

CONNECTOR, USB

Bluetooth Module

ERJ2GE0R00X RESISTOR, 1/16W, 0Ω

This outside (R) is

This outside (R) is