.A complete Parts List is available at www.MillerWelds.com

3-19. Threading Welding Wire Through XR Guns

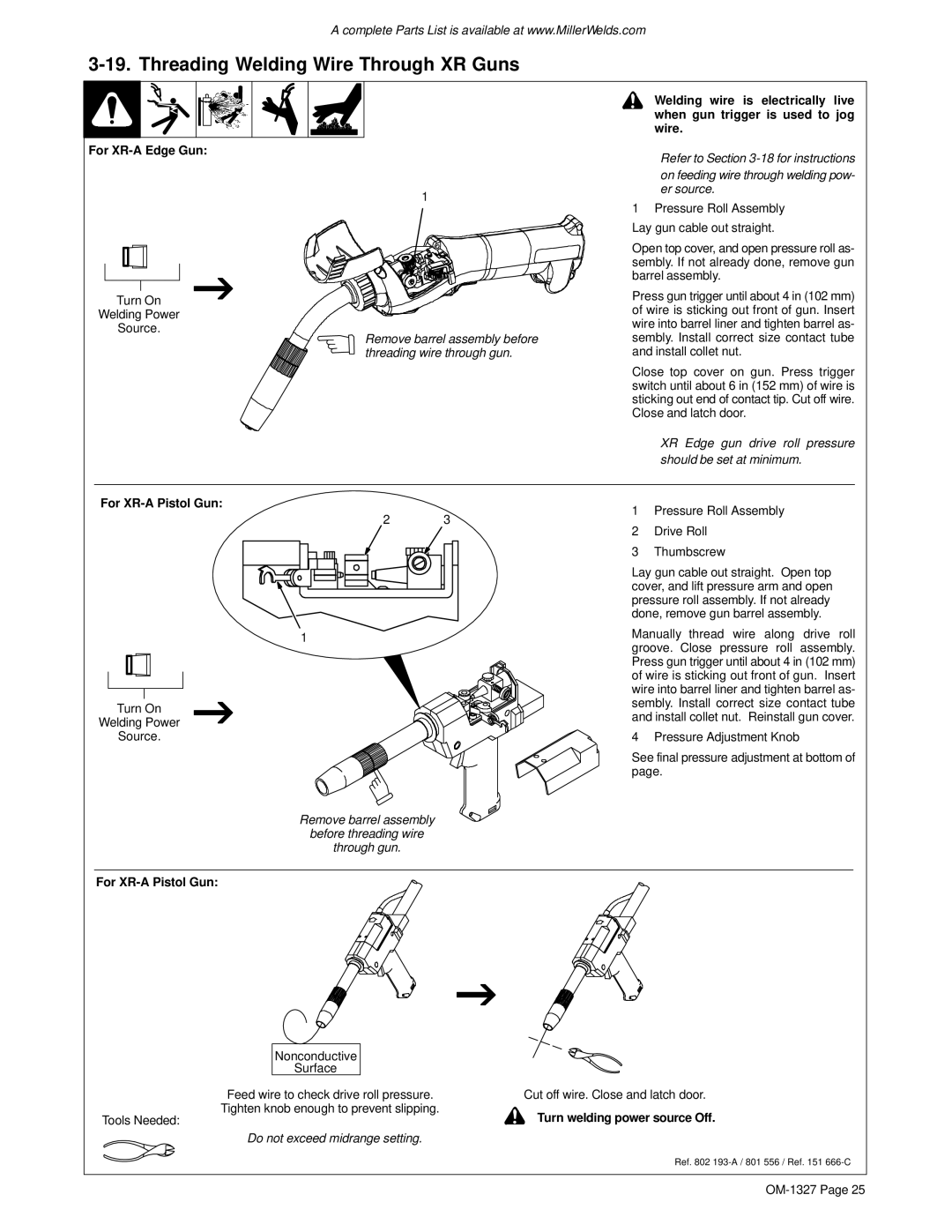

![]() ! Welding wire is electrically live when gun trigger is used to jog wire.

! Welding wire is electrically live when gun trigger is used to jog wire.

For | .Refer to Section |

|

|

|

| on feeding wire through welding pow- | |

| 1 |

| er source. | |

| 1 | Pressure Roll Assembly | ||

|

| |||

|

| Lay gun cable out straight. | ||

|

| Open top cover, and open pressure roll as- | ||

|

| sembly. If not already done, remove gun | ||

|

| barrel assembly. | ||

Turn On |

| Press gun trigger until about 4 in (102 mm) | ||

| of wire is sticking out front of gun. Insert | |||

Welding Power |

| |||

| wire into barrel liner and tighten barrel as- | |||

Source. |

| |||

Remove barrel assembly before | sembly. Install correct size contact tube | |||

threading wire through gun. | and install collet nut. | |||

|

| Close top cover on gun. Press trigger | ||

|

| switch until about 6 in (152 mm) of wire is | ||

|

| sticking out end of contact tip. Cut off wire. | ||

|

| Close and latch door. | ||

|

| .XR Edge gun drive roll pressure | ||

|

|

| should be set at minimum. | |

For |

| 1 | Pressure Roll Assembly | |

2 | 3 | |||

2 | Drive Roll | |||

|

| |||

|

| 3 | Thumbscrew | |

|

| Lay gun cable out straight. Open top | ||

|

| cover, and lift pressure arm and open | ||

|

| pressure roll assembly. If not already | ||

|

| done, remove gun barrel assembly. | ||

1 |

| Manually thread wire along drive roll | ||

| groove. Close pressure roll assembly. | |||

|

| |||

|

| Press gun trigger until about 4 in (102 mm) | ||

|

| of wire is sticking out front of gun. Insert | ||

|

| wire into barrel liner and tighten barrel as- | ||

Turn On |

| sembly. Install correct size contact tube | ||

| and install collet nut. Reinstall gun cover. | |||

Welding Power |

| |||

|

|

| ||

Source. |

| 4 | Pressure Adjustment Knob | |

See final pressure adjustment at bottom of page.

Remove barrel assembly

before threading wire

through gun.

For

Tools Needed:

Nonconductive

Surface

Feed wire to check drive roll pressure. Tighten knob enough to prevent slipping.

.Do not exceed midrange setting.

Cut off wire. Close and latch door.

! Turn welding power source Off.

! Turn welding power source Off.

Ref. 802