.A complete Parts List is available at www.MillerWelds.com

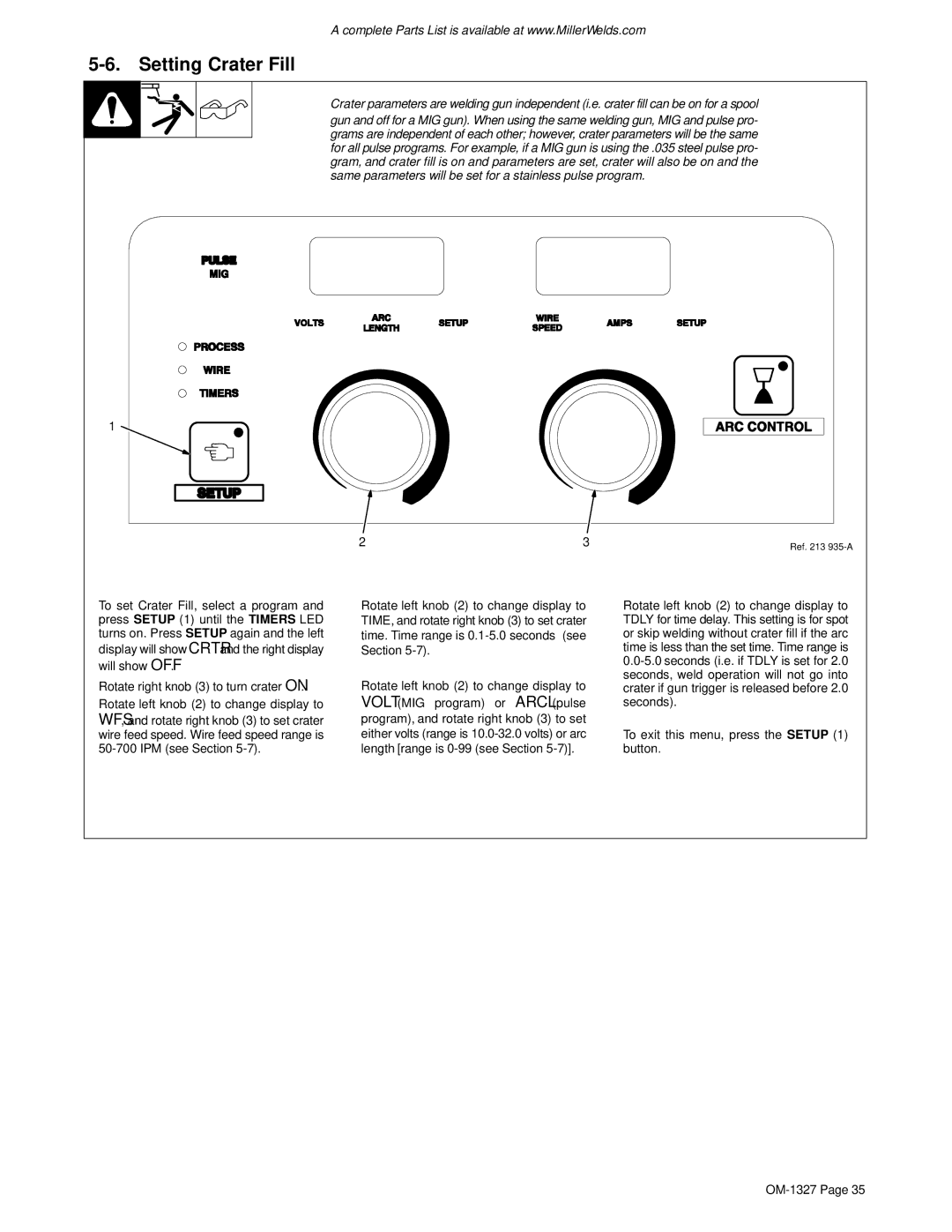

5-6. Setting Crater Fill

.Crater parameters are welding gun independent (i.e. crater fill can be on for a spool

gun and off for a MIG gun). When using the same welding gun, MIG and pulse pro- grams are independent of each other; however, crater parameters will be the same for all pulse programs. For example, if a MIG gun is using the .035 steel pulse pro- gram, and crater fill is on and parameters are set, crater will also be on and the same parameters will be set for a stainless pulse program.

1 ![]()

2 | 3 | Ref. 213 |

|

|

To set Crater Fill, select a program and press SETUP (1) until the TIMERS LED turns on. Press SETUP again and the left

display will show CRTR and the right display

will show OFF.

Rotate right knob (3) to turn crater ON. Rotate left knob (2) to change display to

WFS, and rotate right knob (3) to set crater wire feed speed. Wire feed speed range is

Rotate left knob (2) to change display to TIME, and rotate right knob (3) to set crater time. Time range is

Rotate left knob (2) to change display to VOLT (MIG program) or ARCL (pulse program), and rotate right knob (3) to set either volts (range is

Rotate left knob (2) to change display to TDLY for time delay. This setting is for spot or skip welding without crater fill if the arc time is less than the set time. Time range is

To exit this menu, press the SETUP (1) button.