.A complete Parts List is available at www.MillerWelds.com

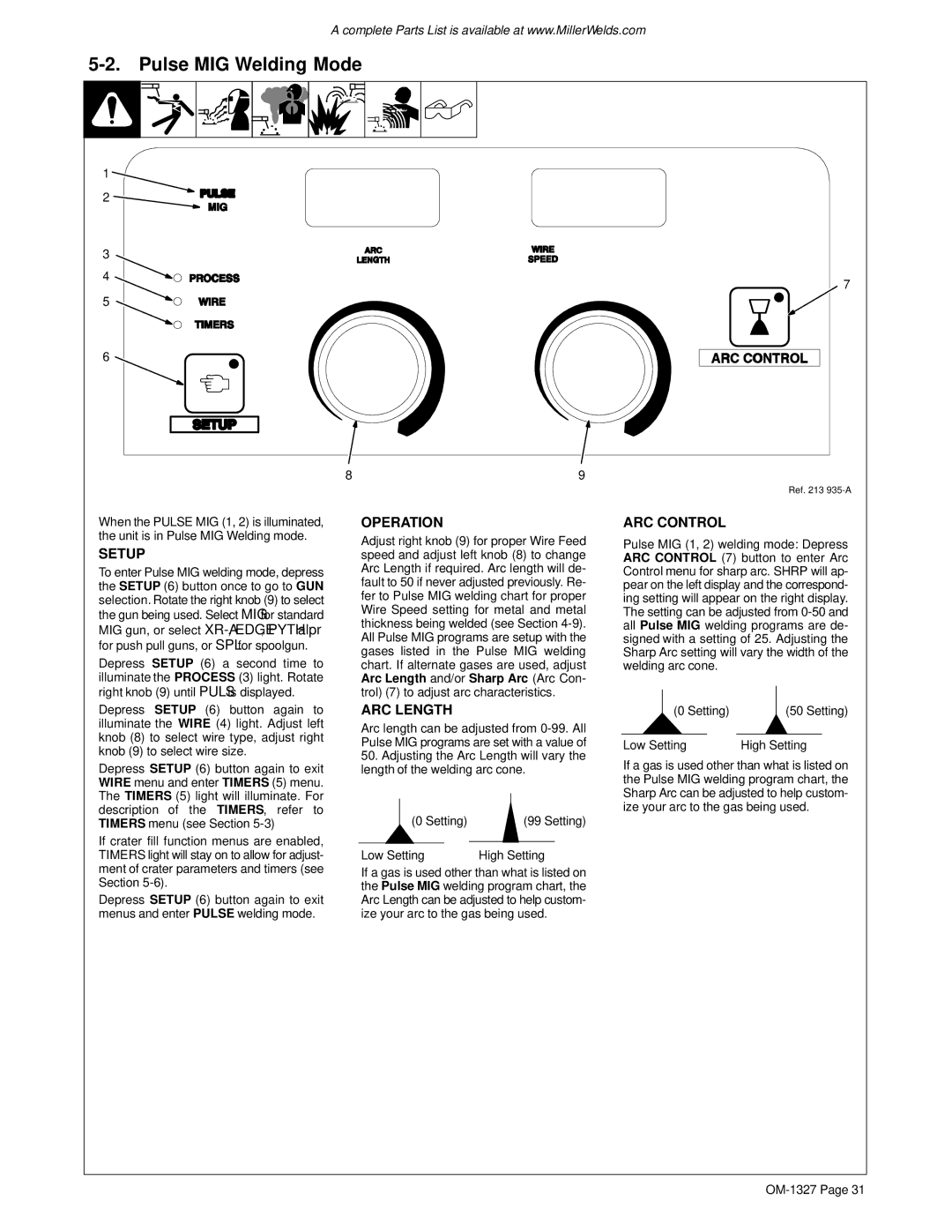

5-2. Pulse MIG Welding Mode

1 ![]()

2 ![]()

3

4

5

6 ![]()

8 | 9 |

7

Ref. 213

When the PULSE MIG (1, 2) is illuminated, the unit is in Pulse MIG Welding mode.

SETUP

To enter Pulse MIG welding mode, depress the SETUP (6) button once to go to GUN selection. Rotate the right knob (9) to select the gun being used. Select MIG for standard MIG gun, or select

Depress SETUP (6) a second time to illuminate the PROCESS (3) light. Rotate right knob (9) until PULS is displayed.

Depress SETUP (6) button again to illuminate the WIRE (4) light. Adjust left knob (8) to select wire type, adjust right knob (9) to select wire size.

Depress SETUP (6) button again to exit WIRE menu and enter TIMERS (5) menu. The TIMERS (5) light will illuminate. For description of the TIMERS, refer to TIMERS menu (see Section

If crater fill function menus are enabled, TIMERS light will stay on to allow for adjust- ment of crater parameters and timers (see Section

Depress SETUP (6) button again to exit menus and enter PULSE welding mode.

OPERATION

Adjust right knob (9) for proper Wire Feed speed and adjust left knob (8) to change Arc Length if required. Arc length will de- fault to 50 if never adjusted previously. Re- fer to Pulse MIG welding chart for proper Wire Speed setting for metal and metal thickness being welded (see Section

ARC LENGTH

Arc length can be adjusted from

50.Adjusting the Arc Length will vary the length of the welding arc cone.

| (0 Setting) |

| (99 Setting) | ||

|

| ||||

|

| ||||

|

|

|

|

|

|

Low Setting | High Setting | ||||

If a gas is used other than what is listed on the Pulse MIG welding program chart, the Arc Length can be adjusted to help custom- ize your arc to the gas being used.

ARC CONTROL

Pulse MIG (1, 2) welding mode: Depress ARC CONTROL (7) button to enter Arc Control menu for sharp arc. SHRP will ap- pear on the left display and the correspond- ing setting will appear on the right display. The setting can be adjusted from

| (0 Setting) |

| (50 Setting) | ||

|

| ||||

| |||||

|

|

|

|

|

|

Low Setting | High Setting | ||||

If a gas is used other than what is listed on the Pulse MIG welding program chart, the Sharp Arc can be adjusted to help custom- ize your arc to the gas being used.