3-3. Duty Cycle And Overheating

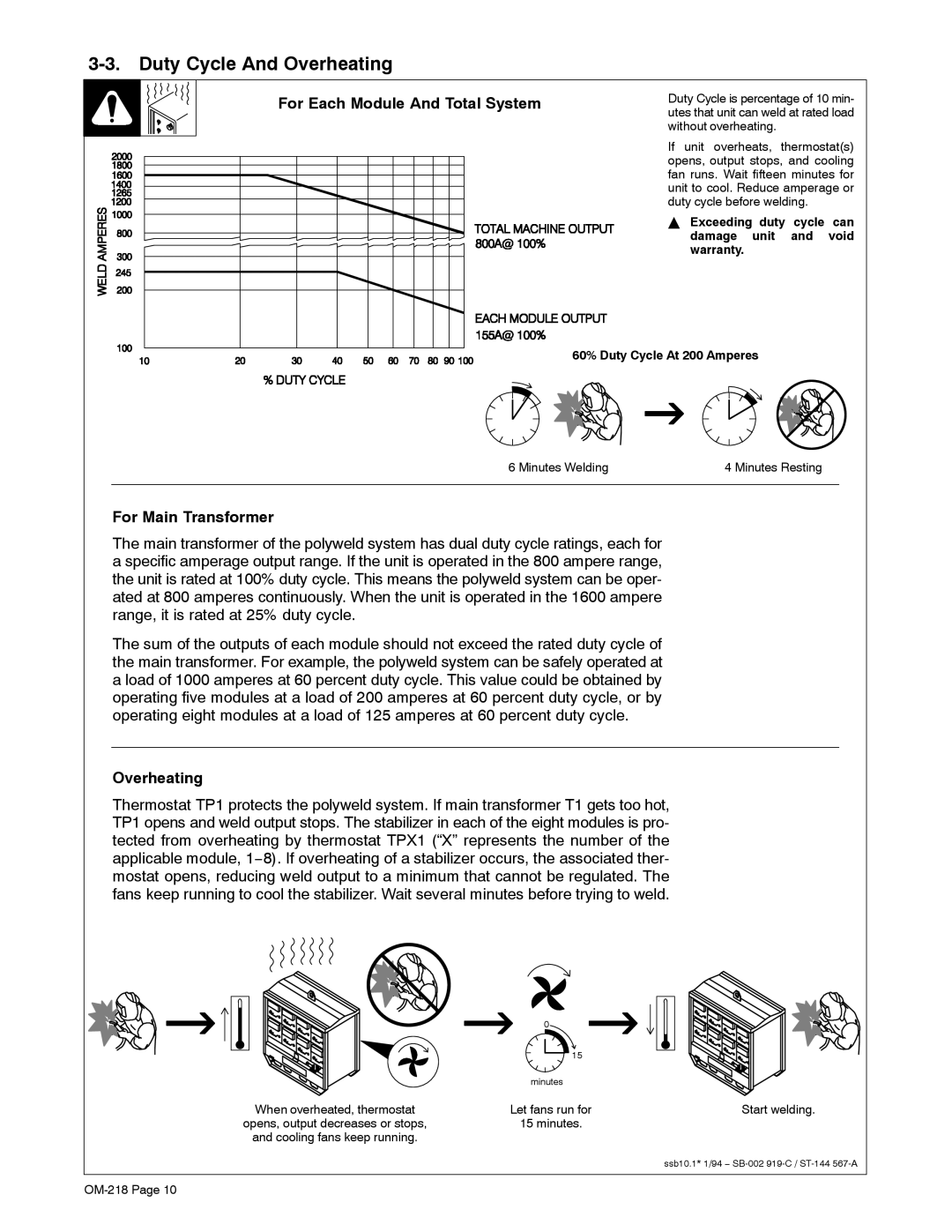

For Each Module And Total System

Duty Cycle is percentage of 10 min- utes that unit can weld at rated load without overheating.

If unit overheats, thermostat(s) opens, output stops, and cooling fan runs. Wait fifteen minutes for unit to cool. Reduce amperage or duty cycle before welding.

Y Exceeding duty cycle can damage unit and void warranty.

60% Duty Cycle At 200 Amperes

6 Minutes Welding | 4 Minutes Resting |

|

|

For Main Transformer

The main transformer of the polyweld system has dual duty cycle ratings, each for a specific amperage output range. If the unit is operated in the 800 ampere range, the unit is rated at 100% duty cycle. This means the polyweld system can be oper- ated at 800 amperes continuously. When the unit is operated in the 1600 ampere range, it is rated at 25% duty cycle.

The sum of the outputs of each module should not exceed the rated duty cycle of the main transformer. For example, the polyweld system can be safely operated at a load of 1000 amperes at 60 percent duty cycle. This value could be obtained by operating five modules at a load of 200 amperes at 60 percent duty cycle, or by operating eight modules at a load of 125 amperes at 60 percent duty cycle.

Overheating

Thermostat TP1 protects the polyweld system. If main transformer T1 gets too hot, TP1 opens and weld output stops. The stabilizer in each of the eight modules is pro- tected from overheating by thermostat TPX1 (“X” represents the number of the applicable module, 1−8). If overheating of a stabilizer occurs, the associated ther- mostat opens, reducing weld output to a minimum that cannot be regulated. The fans keep running to cool the stabilizer. Wait several minutes before trying to weld.

| 0 |

|

| 15 |

|

| minutes |

|

When overheated, thermostat | Let fans run for | Start welding. |

opens, output decreases or stops, | 15 minutes. |

|

and cooling fans keep running. |

|

|

|

| ssb10.1* 1/94 − |