SECTION 8 − SELECTING AND PREPARING

TUNGSTEN ELECTRODE

gtaw 7/97

NOTE

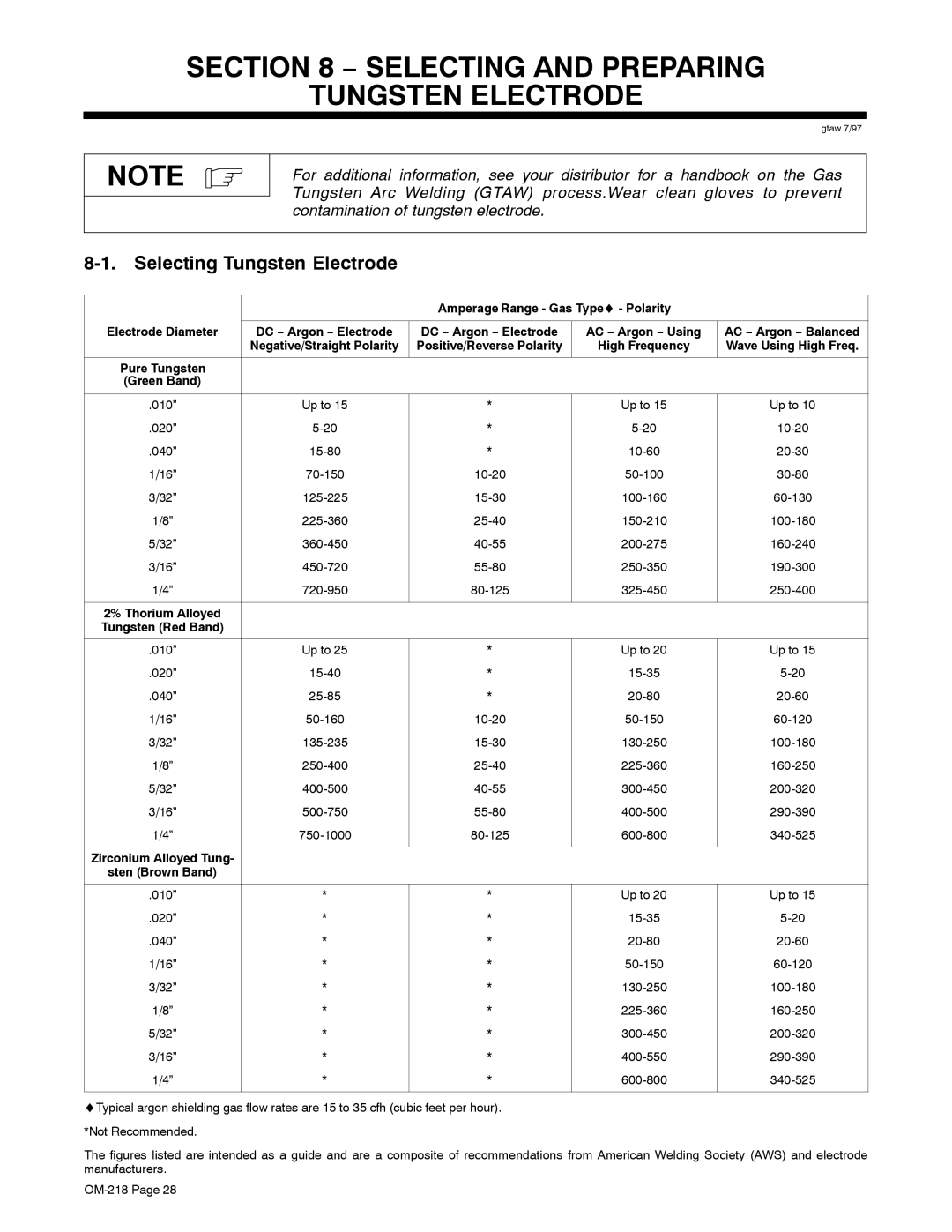

For additional information, see your distributor for a handbook on the Gas Tungsten Arc Welding (GTAW) process.Wear clean gloves to prevent contamination of tungsten electrode.

8-1. Selecting Tungsten Electrode

|

| Amperage Range - Gas Type♦ - Polarity |

| |

|

|

|

|

|

Electrode Diameter | DC − Argon − Electrode | DC − Argon − Electrode | AC − Argon − Using | AC − Argon − Balanced |

| Negative/Straight Polarity | Positive/Reverse Polarity | High Frequency | Wave Using High Freq. |

|

|

|

|

|

Pure Tungsten |

|

|

|

|

(Green Band) |

|

|

|

|

|

|

|

|

|

.010” | Up to 15 | * | Up to 15 | Up to 10 |

.020” | * | |||

.040” | * | |||

1/16” | ||||

3/32” | ||||

1/8” | ||||

5/32” | ||||

3/16” | ||||

1/4” | ||||

|

|

|

|

|

2% Thorium Alloyed |

|

|

|

|

Tungsten (Red Band) |

|

|

|

|

|

|

|

|

|

.010” | Up to 25 | * | Up to 20 | Up to 15 |

.020” | * | |||

.040” | * | |||

1/16” | ||||

3/32” | ||||

1/8” | ||||

5/32” | ||||

3/16” | ||||

1/4” | ||||

|

|

|

|

|

Zirconium Alloyed Tung- |

|

|

|

|

sten (Brown Band) |

|

|

|

|

|

|

|

|

|

.010” | * | * | Up to 20 | Up to 15 |

.020” | * | * | ||

.040” | * | * | ||

1/16” | * | * | ||

3/32” | * | * | ||

1/8” | * | * | ||

5/32” | * | * | ||

3/16” | * | * | ||

1/4” | * | * | ||

|

|

|

|

|

♦Typical argon shielding gas flow rates are 15 to 35 cfh (cubic feet per hour). *Not Recommended.