1

![]()

Electrode Diameter

2

1Tungsten Electrode

2Balled End

YUnderstand and follow safety symbols at start of Section

Ball end of tungsten before welding by applying either an ac amperage slightly higher than what is recom- mended for a given electrode diam- eter (see Section

Ref.

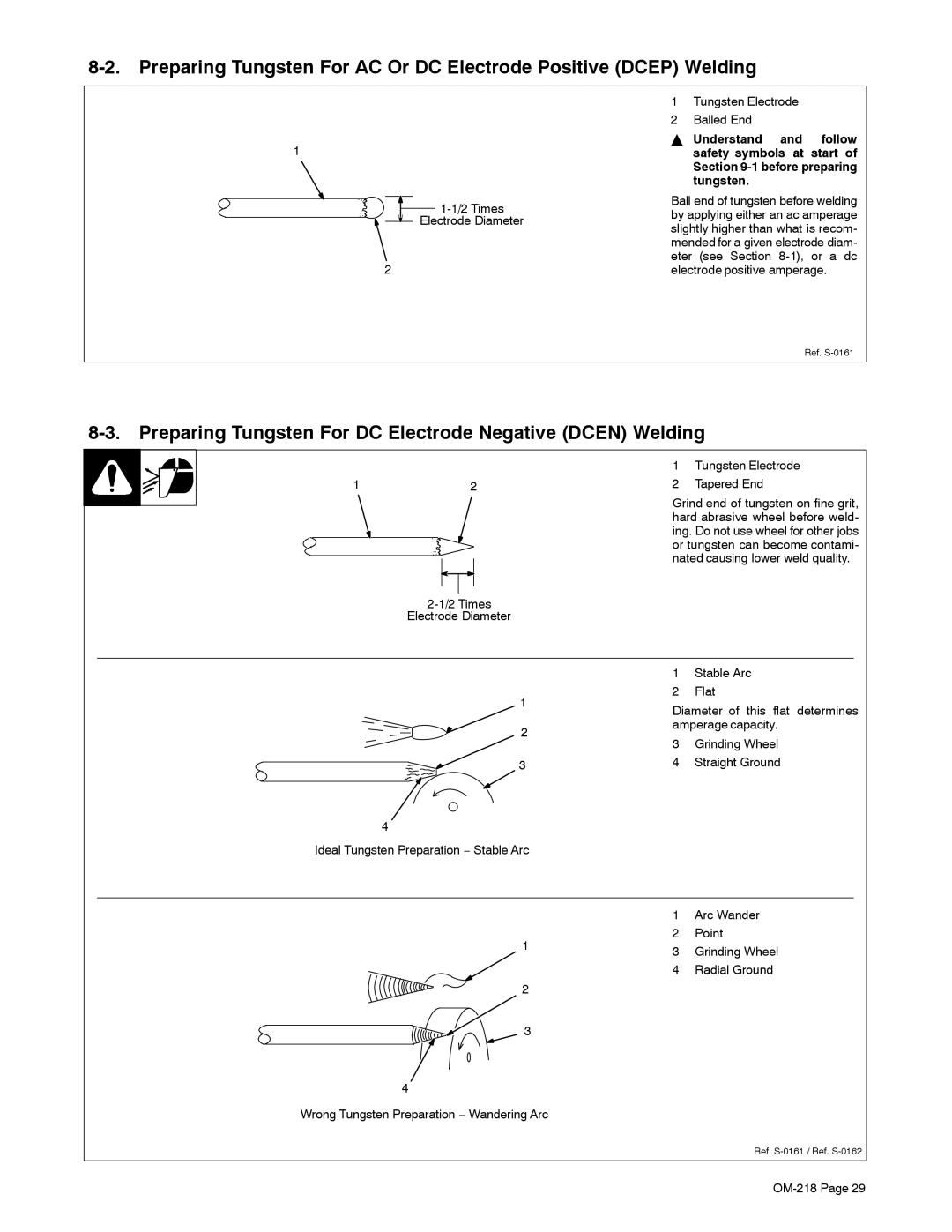

8-3. Preparing Tungsten For DC Electrode Negative (DCEN) Welding

|

| 1 | Tungsten Electrode |

1 | 2 | 2 | Tapered End |

|

| Grind end of tungsten on fine grit, | |

|

| hard abrasive wheel before weld- | |

|

| ing. Do not use wheel for other jobs | |

|

| or tungsten can become contami- | |

|

| nated causing lower weld quality. | |

|

|

| |

| Electrode Diameter |

|

|

|

| 1 | Stable Arc |

| 1 | 2 | Flat |

| Diameter of this flat determines | ||

|

| ||

| 2 | amperage capacity. | |

| 3 | Grinding Wheel | |

|

| ||

| 3 | 4 | Straight Ground |

| 4 |

|

|

Ideal Tungsten Preparation − Stable Arc |

|

| |

|

| 1 | Arc Wander |

| 1 | 2 | Point |

| 3 | Grinding Wheel | |

|

| ||

|

| 4 | Radial Ground |

| 2 |

|

|

| 3 |

|

|

| 4 |

|

|

Wrong Tungsten Preparation − Wandering Arc

Ref.