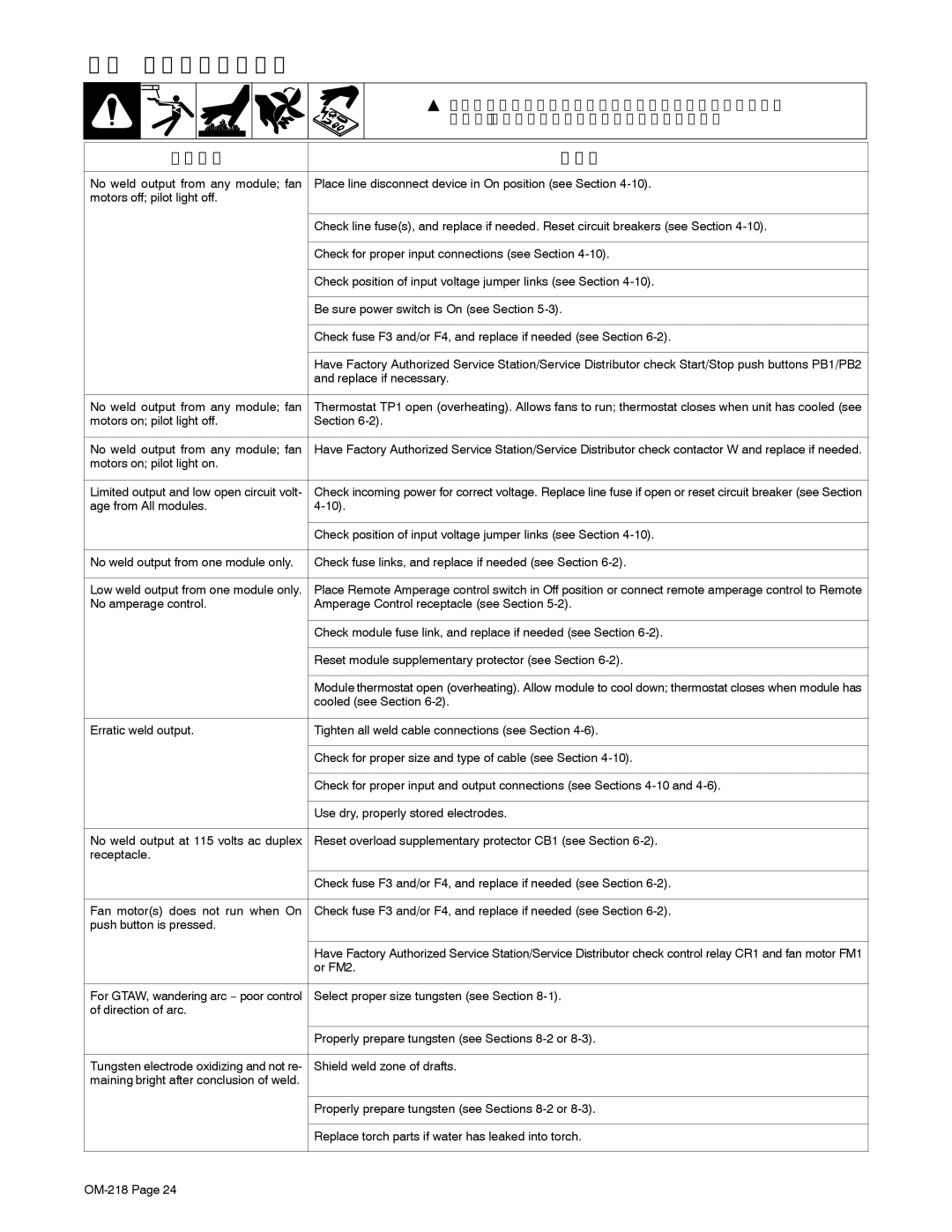

6-4. Troubleshooting

|

|

|

|

|

| Y Turn Off polyweld system, and disconnect input power |

|

|

|

|

|

| before inspecting, maintaining, or servicing. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| Trouble |

| Remedy | |||

|

| |||||

No weld output from any module; fan | Place line disconnect device in On position (see Section | |||||

motors off; pilot light off. |

|

| ||||

|

|

|

|

|

| |

|

|

|

|

| Check line fuse(s), and replace if needed. Reset circuit breakers (see Section | |

|

|

|

|

|

| |

|

|

|

|

| Check for proper input connections (see Section | |

|

|

|

|

|

| |

|

|

|

|

| Check position of input voltage jumper links (see Section | |

|

|

|

|

|

| |

|

|

|

|

| Be sure power switch is On (see Section | |

|

|

|

|

|

| |

|

|

|

|

| Check fuse F3 and/or F4, and replace if needed (see Section | |

|

|

|

|

|

| |

|

|

|

|

| Have Factory Authorized Service Station/Service Distributor check Start/Stop push buttons PB1/PB2 | |

|

|

|

|

| and replace if necessary. | |

|

| |||||

No weld output from any module; fan | Thermostat TP1 open (overheating). Allows fans to run; thermostat closes when unit has cooled (see | |||||

motors on; pilot light off. | Section | |||||

|

| |||||

No weld output from any module; fan | Have Factory Authorized Service Station/Service Distributor check contactor W and replace if needed. | |||||

motors on; pilot light on. |

|

| ||||

|

| |||||

Limited output and low open circuit volt- | Check incoming power for correct voltage. Replace line fuse if open or reset circuit breaker (see Section | |||||

age from All modules. |

| |||||

|

|

|

|

|

| |

|

|

|

|

| Check position of input voltage jumper links (see Section | |

|

| |||||

No weld output from one module only. | Check fuse links, and replace if needed (see Section | |||||

|

| |||||

Low weld output from one module only. | Place Remote Amperage control switch in Off position or connect remote amperage control to Remote | |||||

No amperage control. | Amperage Control receptacle (see Section | |||||

|

|

|

|

|

| |

|

|

|

|

| Check module fuse link, and replace if needed (see Section | |

|

|

|

|

|

| |

|

|

|

|

| Reset module supplementary protector (see Section | |

|

|

|

|

|

| |

|

|

|

|

| Module thermostat open (overheating). Allow module to cool down; thermostat closes when module has | |

|

|

|

|

| cooled (see Section | |

|

| |||||

Erratic weld output. | Tighten all weld cable connections (see Section | |||||

|

|

|

|

|

| |

|

|

|

|

| Check for proper size and type of cable (see Section | |

|

|

|

|

|

| |

|

|

|

|

| Check for proper input and output connections (see Sections | |

|

|

|

|

|

| |

|

|

|

|

| Use dry, properly stored electrodes. | |

|

| |||||

No weld output at 115 volts ac duplex | Reset overload supplementary protector CB1 (see Section | |||||

receptacle. |

|

| ||||

|

|

|

|

|

| |

|

|

|

|

| Check fuse F3 and/or F4, and replace if needed (see Section | |

|

| |||||

Fan motor(s) does not run when On | Check fuse F3 and/or F4, and replace if needed (see Section | |||||

push button is pressed. |

|

| ||||

|

|

|

|

|

| |

|

|

|

|

| Have Factory Authorized Service Station/Service Distributor check control relay CR1 and fan motor FM1 | |

|

|

|

|

| or FM2. | |

|

| |||||

For GTAW, wandering arc − poor control | Select proper size tungsten (see Section | |||||

of direction of arc. |

|

| ||||

|

|

|

|

|

| |

|

|

|

|

| Properly prepare tungsten (see Sections | |

|

| |||||

Tungsten electrode oxidizing and not re- | Shield weld zone of drafts. | |||||

maining bright after conclusion of weld. |

|

| ||||

|

|

|

|

|

| |

|

|

|

|

| Properly prepare tungsten (see Sections | |

|

|

|

|

|

| |

|

|

|

|

| Replace torch parts if water has leaked into torch. | |

|

|

|

|

|

|

|