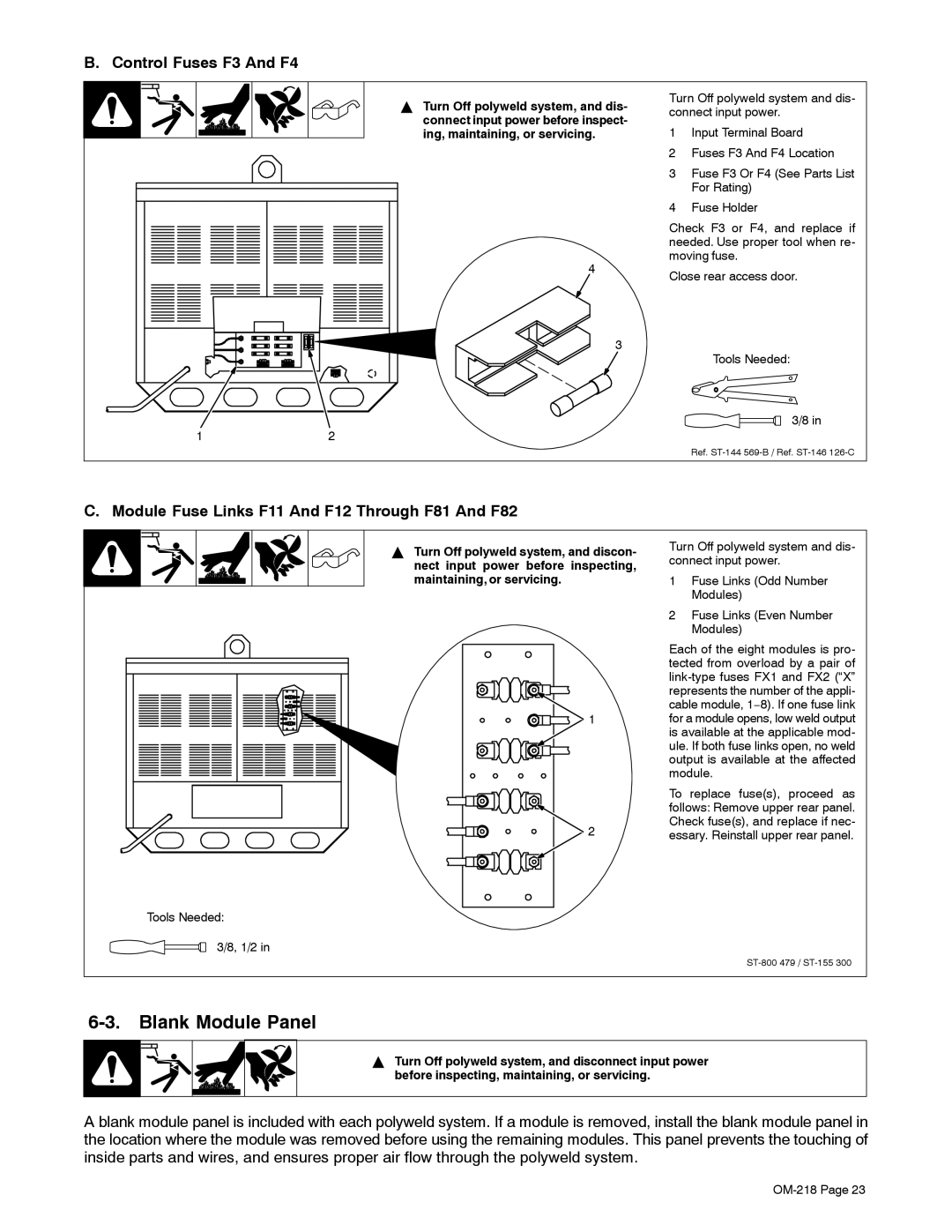

B. Control Fuses F3 And F4

Y Turn Off polyweld system, and dis- connect input power before inspect- ing, maintaining, or servicing.

4

3

12

Turn Off polyweld system and dis- connect input power.

1Input Terminal Board

2Fuses F3 And F4 Location

3Fuse F3 Or F4 (See Parts List For Rating)

4Fuse Holder

Check F3 or F4, and replace if needed. Use proper tool when re- moving fuse.

Close rear access door.

Tools Needed:

3/8 in

Ref.

C. Module Fuse Links F11 And F12 Through F81 And F82

Y Turn Off polyweld system, and discon- nect input power before inspecting, maintaining, or servicing.

![]() 1

1

![]() 2

2

Tools Needed:

3/8, 1/2 in

Turn Off polyweld system and dis- connect input power.

1Fuse Links (Odd Number Modules)

2Fuse Links (Even Number Modules)

Each of the eight modules is pro- tected from overload by a pair of

To replace fuse(s), proceed as follows: Remove upper rear panel. Check fuse(s), and replace if nec- essary. Reinstall upper rear panel.

6-3. Blank Module Panel

Y Turn Off polyweld system, and disconnect input power before inspecting, maintaining, or servicing.

A blank module panel is included with each polyweld system. If a module is removed, install the blank module panel in the location where the module was removed before using the remaining modules. This panel prevents the touching of inside parts and wires, and ensures proper air flow through the polyweld system.