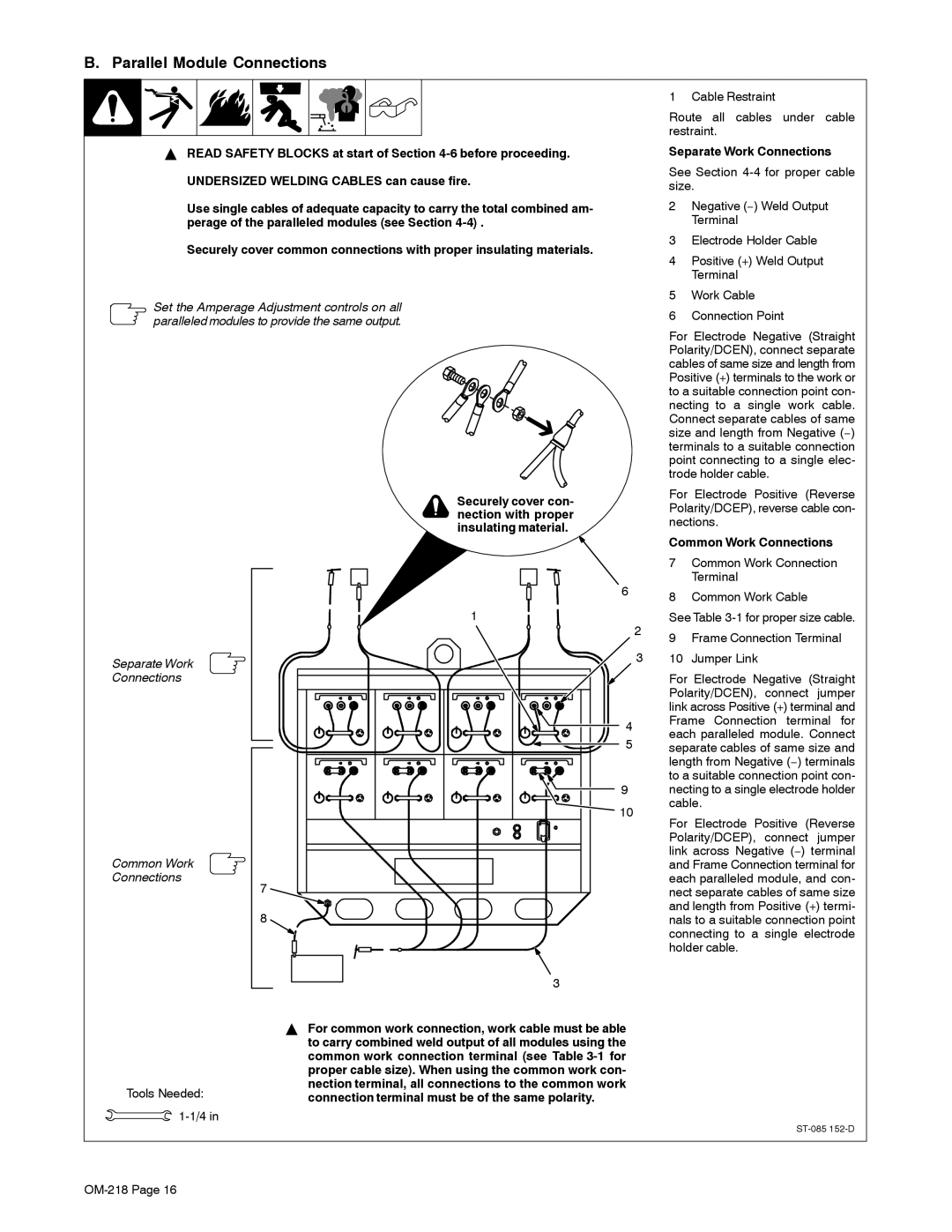

B. Parallel Module Connections

YREAD SAFETY BLOCKS at start of Section

Use single cables of adequate capacity to carry the total combined am- perage of the paralleled modules (see Section

Securely cover common connections with proper insulating materials.

Set the Amperage Adjustment controls on all paralleled modules to provide the same output.

Securely cover con- nection with proper insulating material.

1 Cable Restraint

Route all cables under cable restraint.

Separate Work Connections

See Section

2Negative (−) Weld Output Terminal

3Electrode Holder Cable

4Positive (+) Weld Output Terminal

5Work Cable

6Connection Point

For Electrode Negative (Straight Polarity/DCEN), connect separate cables of same size and length from Positive (+) terminals to the work or to a suitable connection point con- necting to a single work cable. Connect separate cables of same size and length from Negative (−) terminals to a suitable connection point connecting to a single elec- trode holder cable.

For Electrode Positive (Reverse Polarity/DCEP), reverse cable con- nections.

Common Work Connections

Separate Work

Connections

Common Work

Connections

Tools Needed: ![]()

7

8

6

1

2

3

4

5

9

![]() 10

10

3

YFor common work connection, work cable must be able to carry combined weld output of all modules using the common work connection terminal (see Table

7Common Work Connection Terminal

8Common Work Cable

See Table

9Frame Connection Terminal

10Jumper Link

For Electrode Negative (Straight Polarity/DCEN), connect jumper link across Positive (+) terminal and Frame Connection terminal for each paralleled module. Connect separate cables of same size and length from Negative (−) terminals to a suitable connection point con- necting to a single electrode holder cable.

For Electrode Positive (Reverse Polarity/DCEP), connect jumper link across Negative (−) terminal and Frame Connection terminal for each paralleled module, and con- nect separate cables of same size and length from Positive (+) termi- nals to a suitable connection point connecting to a single electrode holder cable.