HBDV7 Series Direct Vent Gas Fireplace | VENTING INSTALLATION |

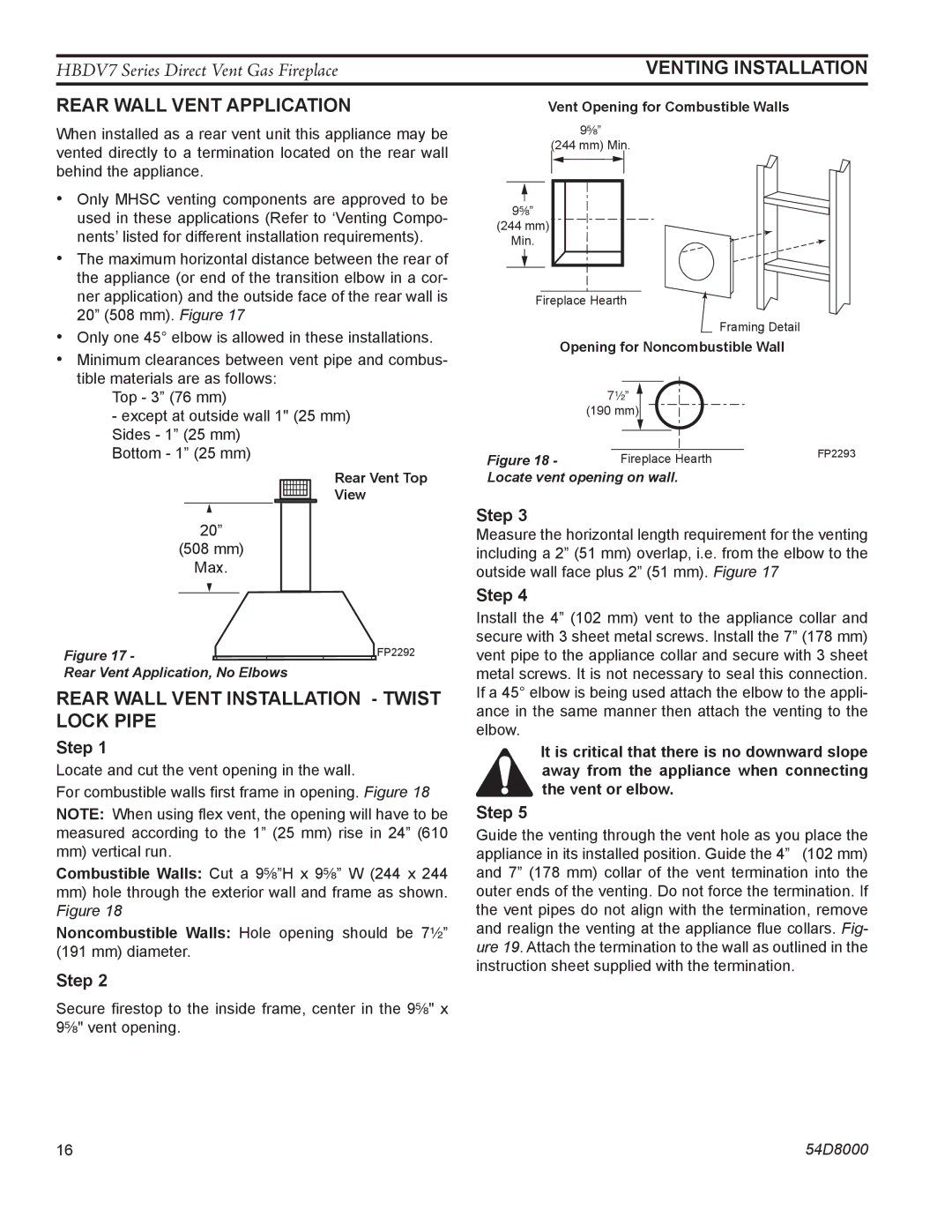

Rear Wall Vent Application

When installed as a rear vent unit this appliance may be vented directly to a termination located on the rear wall behind the appliance.

•Only MHSC venting components are approved to be used in these applications (Refer to ‘Venting Compo- nents’ listed for different installation requirements).

•The maximum horizontal distance between the rear of the appliance (or end of the transition elbow in a cor- ner application) and the outside face of the rear wall is 20” (508 mm). Figure 17

•Only one 45° elbow is allowed in these installations.

•Minimum clearances between vent pipe and combus- tible materials are as follows:

Top - 3” (76 mm)

-except at outside wall 1" (25 mm)

Sides - 1” (25 mm)

Bottom - 1” (25 mm)

Rear Vent Top

View

20”

(508 mm)

Max.

Figure 17 - | FP2292 |

Rear Vent Application, No Elbows |

|

REAR WALL VENT INSTALLATION - TWIST LOCK PIPE

Step 1

Locate and cut the vent opening in the wall.

For combustible walls first frame in opening. Figure 18

NOTE: When using flex vent, the opening will have to be measured according to the 1” (25 mm) rise in 24” (610 mm) vertical run.

Combustible Walls: Cut a 9B\,”H x 9B\,” W (244 x 244

mm)hole through the exterior wall and frame as shown. Figure 18

Noncombustible Walls: Hole opening should be 7Z\x” (191 mm) diameter.

Step 2

Secure firestop to the inside frame, center in the 9B\," x 9B\," vent opening.

Vent Opening for Combustible Walls

9B\,”

(244 mm) Min.

9B\,”

(244 mm)

Min.

Fireplace Hearth

Framing Detail

Opening for Noncombustible Wall

| 7Z\x” |

|

|

| |||

|

|

| |||||

| (190 mm) |

|

|

| |||

|

|

|

|

|

|

| FP2293 |

|

|

|

|

|

|

| |

Figure 18 - |

| Fireplace Hearth | |||||

|

| ||||||

Locate vent opening on wall.

Step 3

Measure the horizontal length requirement for the venting including a 2” (51 mm) overlap, i.e. from the elbow to the outside wall face plus 2” (51 mm). Figure 17

Step 4

Install the 4” (102 mm) vent to the appliance collar and secure with 3 sheet metal screws. Install the 7” (178 mm) vent pipe to the appliance collar and secure with 3 sheet metal screws. It is not necessary to seal this connection. If a 45° elbow is being used attach the elbow to the appli- ance in the same manner then attach the venting to the elbow.

It is critical that there is no downward slope away from the appliance when connecting the vent or elbow.

Step 5

Guide the venting through the vent hole as you place the appliance in its installed position. Guide the 4” (102 mm) and 7” (178 mm) collar of the vent termination into the outer ends of the venting. Do not force the termination. If the vent pipes do not align with the termination, remove and realign the venting at the appliance flue collars. Fig- ure 19. Attach the termination to the wall as outlined in the instruction sheet supplied with the termination.

16 | 54D8000 |