Model C30HDZ

Proposition 65WARNING

SILICOSIS/RESPIRATORYWARNING

Table of Contents

Best Deal! Order via Internet Dealers Only

Parts Ordering Procedures

Order via Fax Dealers Only

30HDZ Pump Specifications

Pump Specifications

C30HDZ Concrete Pump Dimensions

Pump Dimensions

You can be injured if you do not follow directions

Structure that does not provide ample free flow air

Always wear approved eye and hearing protection

Always wear approved respiratory protection

High Temperatures Allow the engine

General Safety

Rules for Safe Operation

Do not use worn out hoses or couplings inspect daily

Rules for Safe Operation

Lifting

Maintenance Safety

Emergencies

Page

Towing Guidelines

Recommended Maintenance

PumpTrailer Vehicle Connection

Towing Applications

Trailer Safety Precautions

Trailer Safety Guidelines

Torsion Bar Suspension

Always wear safety glasses when

Tires/Wheels/Lug Nuts

TiresWear/Inflation

Start all wheel lug nuts by hand

Lug Nut Torque Requirements

Page

Operation and Safety Decals

Operation and Safety Decals

Operation Hand Signals

Important Hand Signals

Major Pump Components

Pump Components

Pump Components

Pump Control Box Components

Control BOX Components

Front Viewrearview

Engine Components

Pump Mix Guidelines

General Information

Sample Design Mix 3000 Psi 3/8 in. Slump 4- 5

Pumping Cylinder

HOW IT Works

Pumping Pistons

Bearing

Operating Suggestions

Admixtures

Operating Information

New Pumps

Pumping Tips

Clearing a Mix from the System

Stop the pump. Switch OFF the engine

Avoiding Setting of the Mix in the System

Clearing a Plugged Manifold

Itisstronglyrecommendedthatsteel

Down-Hill Pumping

VerticalPumping

Pulsation

Snap-Joint

Cam Roller

Engine Oil Check

Read safety instructions at the beginning of this manual

Inspection

Before Starting

Lubrication Box

Gasoline Check

Belt Deflection

Inches 8 to 12 mm

Turn the ignition key to the OFF position

Place the pumping control switch in the OFF position Figure

Starting

Below 1300 RPMs

Preventive Maintenance

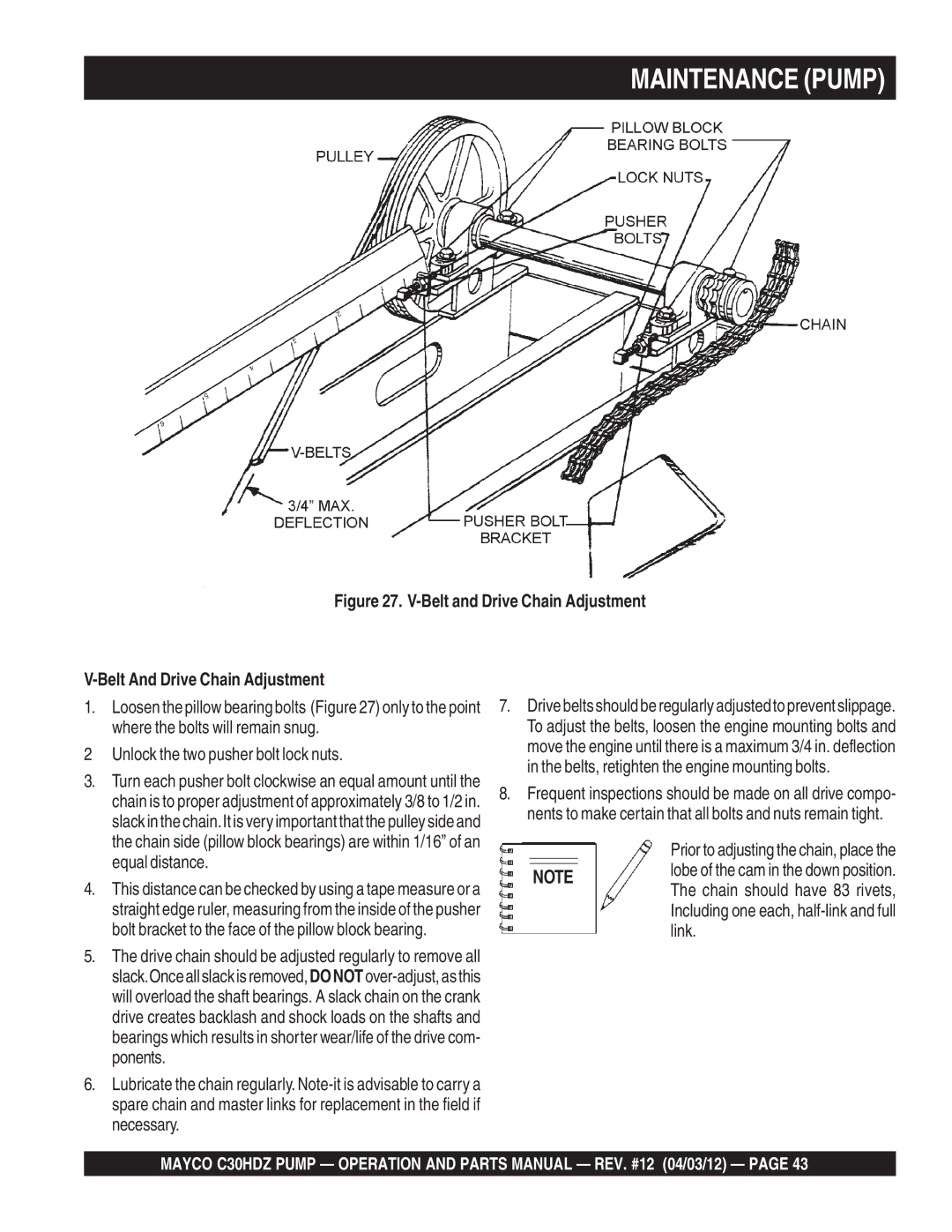

Maintenance Pump

General Clean-up Procedure

Piston CupWear

Sponge Clean-out Procedure

Make sure the eccentric lock is Pumping unit

Crankshaft and Cam Assembly Procedure

Clutch lining is a normal

Following procedure will assist you in replacing the lining

Bearing/Cam Bushing Installation

Bearing Installation

Detent holes will prevent

Detent Hole 3 Installation

Position the ‘O’ring on the O.D.of

Maintenance Pump

Working Loads

Installation and Drive Alignment

Roller Chain Application

Diamond Chain Companytm

Chain-Link Cross Section

Drive Chain Lubrication

Chain-Link Pin Removal

Installation Of Coversides

Installation of Spring Locks and Cotter-Pins

Assembling and Disassembling Drive Chain

For more detail troubleshooting methods, refer

Enginetroubleshooting

Unions a required

Enginetroubleshooting

Sympton Possible Problem Solution

Fuel tank empty? Replace fuel filter Fuel filter clogged?

Page

Wiring Diagram

Wiring Diagram

Wiring Diagram Tail Lights

Appendix Slumptest Procedure

Pea Gravel 100 Comb

Gallons per sack

Material #16 #30 #50

Sand 100

Appendix Concrete MIX Information

2749

2708

2775

2685

Recommended Shotcrete System

Appendix Recommended Shotcrete System

General recommendations

Part Name QTY. Remarks

Passages clean

Recommended Shotcrete Accessories

Has Passedthroughthe Entire Hose Length

Appendix Recommended Shotcrete Accessories

Xxxxx only Not Used on

Explanation of Code in Remarks Column

Description QTY

Suggested Spare Parts

Name Plate and Decals

Nameplate and Decals

DECAL, Multiquip Mayco

DECAL, Maintenance

DECAL, Caution OIL Level

DECAL, CAUTION, Manifold

Compensator Piston ROD Assy

Compensator Piston ROD Assy

Bearing CUP

Spring Return

Piston Guide Assy

Fitting

Connecting ROD Drive Side Assy

30HDN Pump Connecting ROD Drive Side Assy

Piston ROD Assy

KIT

Rocker Assy

Rocker Assy

Countershaft Assy

COUNTER-SHAFT Assy

WASHER, LOCK1/2

Counter Shaft

CAM Bearing

Washer Williams 1/2

Crankshaft Assy

Crankshaft Assy

Zerk Fitting Bolt 5/8-11X4 HEX Head WASHER, Special 5/8

Crankshaft Assy

Bearing Block

Lock Washer 3/4

Manifold Assy

Manifold Assy

Manifold Assy

Frame Assy

Frame Assy

Frame Assy

Axle Assy

Axle Assy

Axle Assy

MUFFLER, AIR Filter and Stop Switch Assy

MUFFLER, AIR FILTER, and Stop Switch Assy

Gland Connector

PRECLEANER, AIR Filter

BRACKET, AIR Cleaner Pipe

Stop SWITCH, Engine Cover

Clutch Assy

Clutch Assy

Clutch Assy

Engine Mounting Assy Secure to Frame

Engine Mounting Assy

OIL Cooler

Engine Support Block Side

Deutz Engine

Throttle Assy

Throttle Assy

Control BOX Mounting Bracket Assy

Control BOX Mounting Bracket Assy

WASHER, Flat 1/4

Control BOX Assy

Control BOX Assy

Control BOX Assy

RED Pilot Lens Battery

Battery Assy

Battery Assy

Battery Assy

Fuel Tank Assy

Fueltank Assy

Fueltank Assy

Hopper Assy

Hopper Assy

Washer 5/8 Flat

Hopper Assy

Hopper

PIN, Hair

Hood Assy

Hood Assy

Manual Holder

Rivet

Latch KIT

BUMPER, Rubber

Location

Lubrication Panel Assy

Lubrication Panel Assy

Position

1FT=1PC

FITTING, Grease 1/8 NPT

Straight Fitting 1/8 NPT

Coupling W/NUT 1/8 NPT

Remote Control Cable Assy

Remote Control Cable Assy

Grip Cord Seal

SWITCH, Micro

CONNECTOR, 3/16 Ring

Junction BOX

Minimum Order

Special Expediting Service

Payment Terms

Freight Policy

Mechanical Drive Models

Mayco Pumpwarranty

HERE’S HOW to GET Help