DCA-600SSV —TRAILER BRAKES MAINTENANCE

Electric Brakes

Electrically actuated brakes (Figure 72) are similar to hydraulic brakes. The basic difference is that hydraulic brakes are actuated by an electromagnet. Listed below are some of the advantages that electric brakes have over hydraulic brakes:

Brake system can be manually adjusted to provide the corrected braking capability for varying road and load conditions.

Brake system can be modulated to provide more or less braking force, thus easing the brake load on the towing vehicle.

Brake system has very little lag time between the time the vehicle’s brakes are actuated and the trailer’s brakes are actuated.

Brake system can provide an independent emergency brake system.

Remember in order to properly synchronize the tow vehicle’s braking to the trailer’s braking, can only be accomplished by road testing. Brake lockup, grabbiness or harshness is due to lack of synchronization between the tow vehicle and the trailer being towed or

Before any brake synchronizations adjustments can be made, the trailer brakes should be

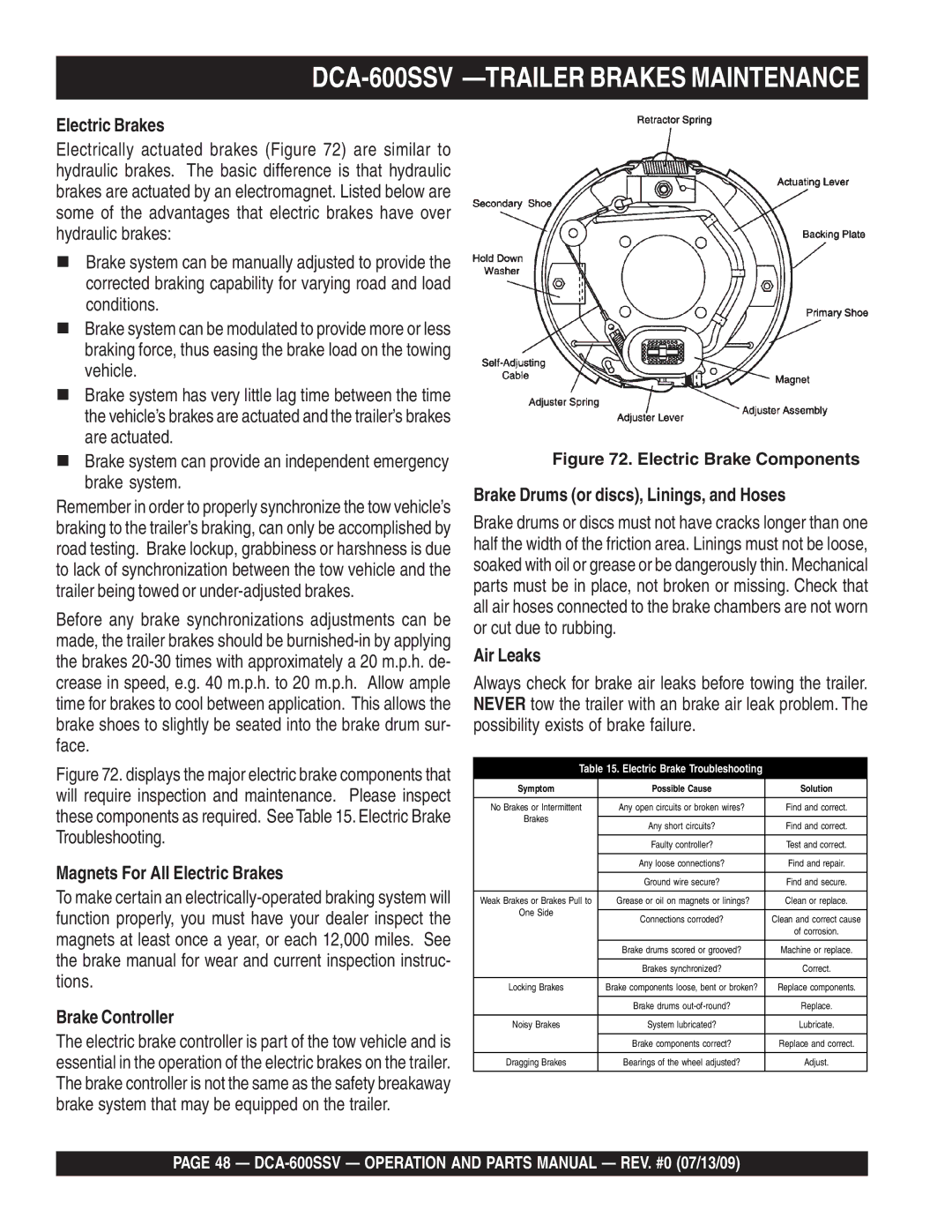

Figure 72. displays the major electric brake components that will require inspection and maintenance. Please inspect these components as required. See Table 15. Electric Brake Troubleshooting.

Magnets For All Electric Brakes

To make certain an

Brake Controller

The electric brake controller is part of the tow vehicle and is essential in the operation of the electric brakes on the trailer. The brake controller is not the same as the safety breakaway brake system that may be equipped on the trailer.

Figure 72. Electric Brake Components

Brake Drums (or discs), Linings, and Hoses

Brake drums or discs must not have cracks longer than one half the width of the friction area. Linings must not be loose, soaked with oil or grease or be dangerously thin. Mechanical parts must be in place, not broken or missing. Check that all air hoses connected to the brake chambers are not worn or cut due to rubbing.

Air Leaks

Always check for brake air leaks before towing the trailer. NEVER tow the trailer with an brake air leak problem. The possibility exists of brake failure.

Table 15. Electric Brake Troubleshooting

Symptom | Possible Cause | Solution | |

|

|

| |

No Brakes or Intermittent | Any open circuits or broken wires? | Find and correct. | |

Brakes |

|

| |

Any short circuits? | Find and correct. | ||

| |||

|

|

| |

| Faulty controller? | Test and correct. | |

|

|

| |

| Any loose connections? | Find and repair. | |

|

|

| |

| Ground wire secure? | Find and secure. | |

|

|

| |

Weak Brakes or Brakes Pull to | Grease or oil on magnets or linings? | Clean or replace. | |

One Side |

|

| |

Connections corroded? | Clean and correct cause | ||

| |||

|

| of corrosion. | |

|

|

| |

| Brake drums scored or grooved? | Machine or replace. | |

|

|

| |

| Brakes synchronized? | Correct. | |

|

|

| |

Locking Brakes | Brake components loose, bent or broken? | Replace components. | |

|

|

| |

| Brake drums | Replace. | |

|

|

| |

Noisy Brakes | System lubricated? | Lubricate. | |

|

|

| |

| Brake components correct? | Replace and correct. | |

|

|

| |

Dragging Brakes | Bearings of the wheel adjusted? | Adjust. | |

|

|

|

PAGE 48 —