10

3.1VENTING LENGTHS AND COMPONENTS

Use only Wolf Steel, Simpson

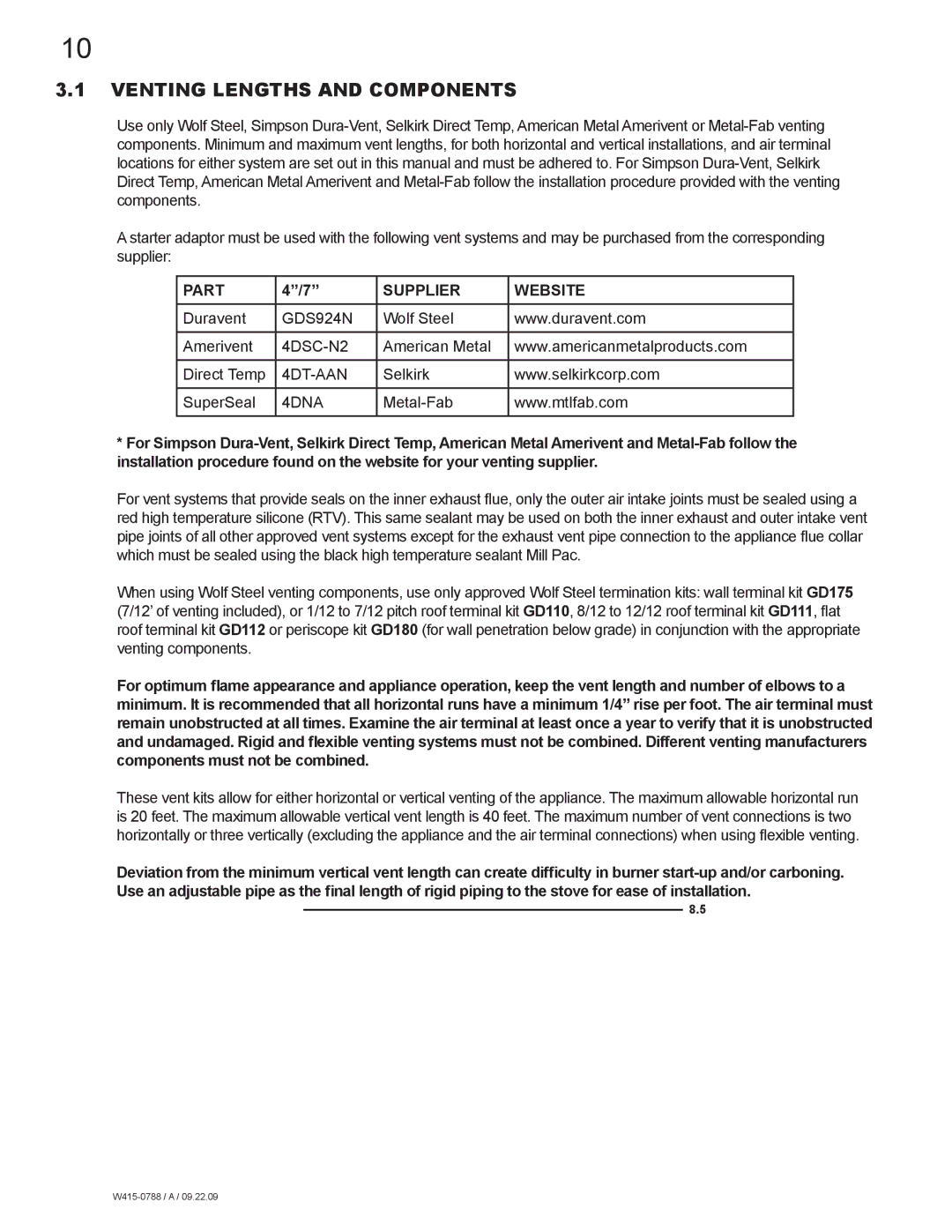

A starter adaptor must be used with the following vent systems and may be purchased from the corresponding supplier:

PART | 4”/7” | SUPPLIER | WEBSITE |

|

|

|

|

Duravent | GDS924N | Wolf Steel | www.duravent.com |

|

|

|

|

Amerivent | American Metal | www.americanmetalproducts.com | |

|

|

|

|

Direct Temp | Selkirk | www.selkirkcorp.com | |

|

|

|

|

SuperSeal | 4DNA | www.mtlfab.com | |

|

|

|

|

*For Simpson

For vent systems that provide seals on the inner exhaust flue, only the outer air intake joints must be sealed using a red high temperature silicone (RTV). This same sealant may be used on both the inner exhaust and outer intake vent pipe joints of all other approved vent systems except for the exhaust vent pipe connection to the appliance flue collar which must be sealed using the black high temperature sealant Mill Pac.

When using Wolf Steel venting components, use only approved Wolf Steel termination kits: wall terminal kit GD175 (7/12’ of venting included), or 1/12 to 7/12 pitch roof terminal kit GD110, 8/12 to 12/12 roof terminal kit GD111, flat roof terminal kit GD112 or periscope kit GD180 (for wall penetration below grade) in conjunction with the appropriate venting components.

For optimum flame appearance and appliance operation, keep the vent length and number of elbows to a minimum. It is recommended that all horizontal runs have a minimum 1/4” rise per foot. The air terminal must remain unobstructed at all times. Examine the air terminal at least once a year to verify that it is unobstructed and undamaged. Rigid and flexible venting systems must not be combined. Different venting manufacturers components must not be combined.

These vent kits allow for either horizontal or vertical venting of the appliance. The maximum allowable horizontal run is 20 feet. The maximum allowable vertical vent length is 40 feet. The maximum number of vent connections is two horizontally or three vertically (excluding the appliance and the air terminal connections) when using flexible venting.

Deviation from the minimum vertical vent length can create difficulty in burner

8.5