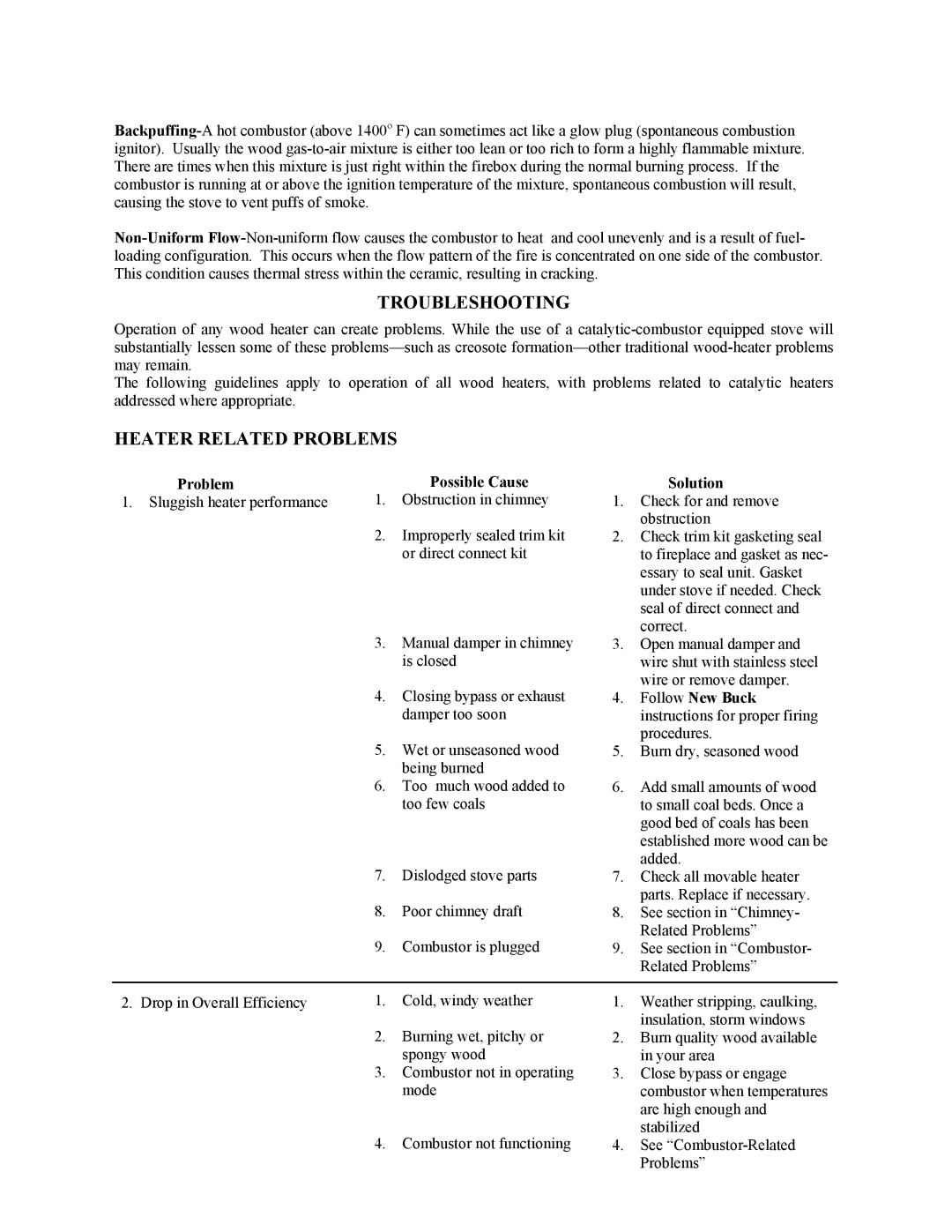

TROUBLESHOOTING

Operation of any wood heater can create problems. While the use of a

The following guidelines apply to operation of all wood heaters, with problems related to catalytic heaters addressed where appropriate.

HEATER RELATED PROBLEMS

| Problem |

| Possible Cause |

| Solution |

1. | Sluggish heater performance | 1. | Obstruction in chimney | 1. | Check for and remove |

|

| 2. | Improperly sealed trim kit |

| obstruction |

|

| 2. | Check trim kit gasketing seal | ||

|

|

| or direct connect kit |

| to fireplace and gasket as nec- |

|

|

|

|

| essary to seal unit. Gasket |

|

|

|

|

| under stove if needed. Check |

|

|

|

|

| seal of direct connect and |

|

| 3. | Manual damper in chimney |

| correct. |

|

| 3. | Open manual damper and | ||

|

|

| is closed |

| wire shut with stainless steel |

|

| 4. | Closing bypass or exhaust |

| wire or remove damper. |

|

| 4. | Follow New Buck | ||

|

|

| damper too soon |

| instructions for proper firing |

|

| 5. | Wet or unseasoned wood |

| procedures. |

|

| 5. | Burn dry, seasoned wood | ||

|

|

| being burned |

|

|

|

| 6. | Too much wood added to | 6. | Add small amounts of wood |

|

|

| too few coals |

| to small coal beds. Once a |

|

|

|

|

| good bed of coals has been |

|

|

|

|

| established more wood can be |

|

| 7. | Dislodged stove parts |

| added. |

|

| 7. | Check all movable heater | ||

|

| 8. | Poor chimney draft |

| parts. Replace if necessary. |

|

| 8. | See section in “Chimney- | ||

|

| 9. | Combustor is plugged |

| Related Problems” |

|

| 9. | See section in “Combustor- | ||

|

|

|

|

| Related Problems” |

|

|

|

|

|

|

2. | Drop in Overall Efficiency | 1. | Cold, windy weather | 1. | Weather stripping, caulking, |

|

| 2. | Burning wet, pitchy or |

| insulation, storm windows |

|

| 2. | Burn quality wood available | ||

|

|

| spongy wood |

| in your area |

|

| 3. | Combustor not in operating | 3. | Close bypass or engage |

|

|

| mode |

| combustor when temperatures |

|

|

|

|

| are high enough and |

|

| 4. | Combustor not functioning |

| stabilized |

|

| 4. | See | ||

|

|

|

|

| Problems” |