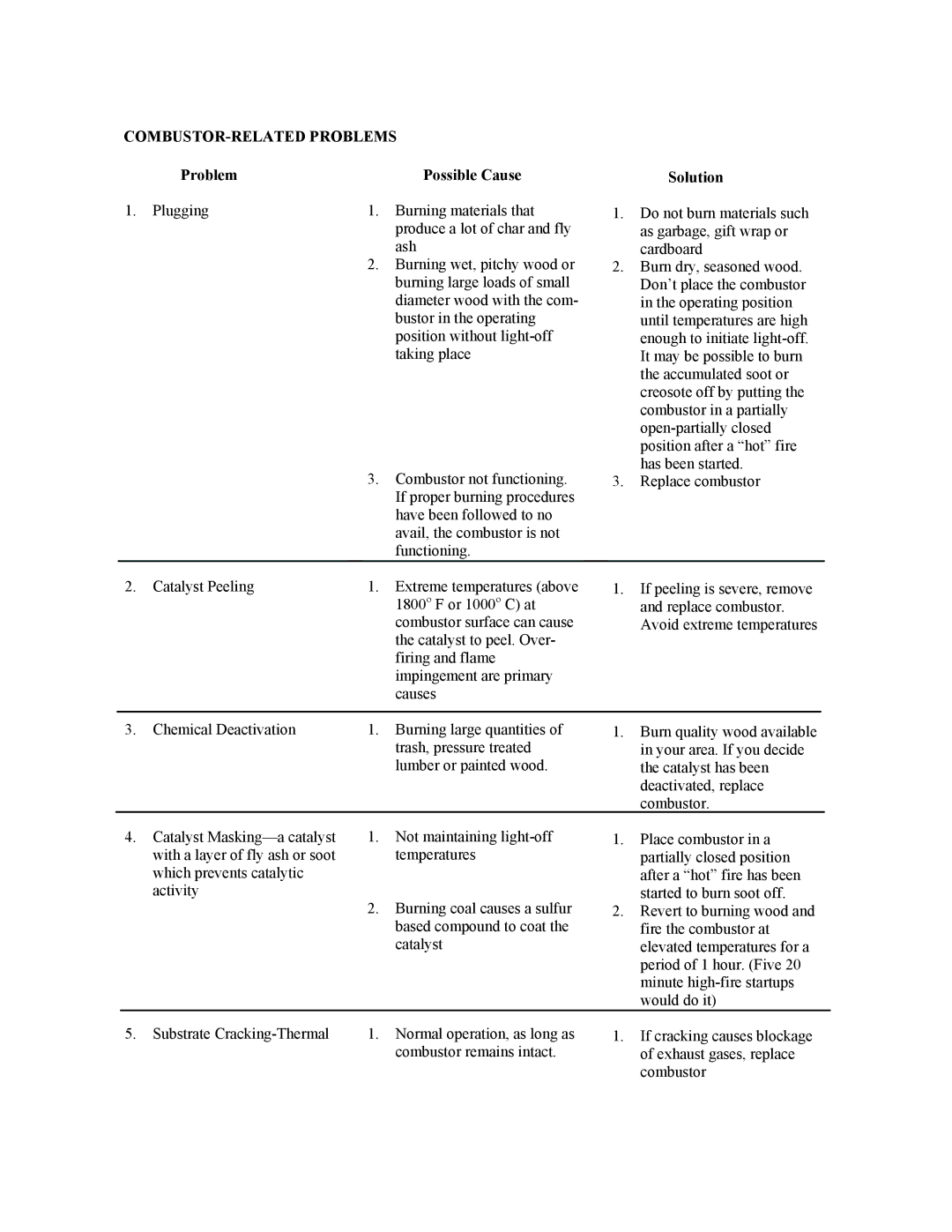

COMBUSTOR-RELATED PROBLEMS

Problem | Possible Cause |

1. Plugging | 1. Burning materials that |

| produce a lot of char and fly |

| ash |

| 2. Burning wet, pitchy wood or |

| burning large loads of small |

| diameter wood with the com- |

| bustor in the operating |

| position without |

| taking place |

3. Combustor not functioning. If proper burning procedures have been followed to no avail, the combustor is not functioning.

Solution

1.Do not burn materials such as garbage, gift wrap or cardboard

2.Burn dry, seasoned wood. Don’t place the combustor in the operating position until temperatures are high enough to initiate

3.Replace combustor

2. Catalyst Peeling | 1. Extreme temperatures (above |

| 1800o F or 1000o C) at |

| combustor surface can cause |

| the catalyst to peel. Over- |

| firing and flame |

| impingement are primary |

| causes |

1.If peeling is severe, remove and replace combustor. Avoid extreme temperatures

3. Chemical Deactivation | 1. Burning large quantities of |

| trash, pressure treated |

| lumber or painted wood. |

1.Burn quality wood available in your area. If you decide the catalyst has been deactivated, replace combustor.

4.Catalyst

1.Not maintaining

2.Burning coal causes a sulfur based compound to coat the catalyst

1.Place combustor in a partially closed position after a “hot” fire has been started to burn soot off.

2.Revert to burning wood and fire the combustor at elevated temperatures for a period of 1 hour. (Five 20 minute

5. Substrate | 1. Normal operation, as long as |

| combustor remains intact. |

1.If cracking causes blockage of exhaust gases, replace combustor