Page: 110

Service Guide ML520/521

Chapter 3 Maintenance & Disassembly

3.4 CLEANING

3.4.01 General Information

An accumulation of paper dust is the most frequent cause of print quality problems in a dot matrix printer. Small pieces of paper can cause paper jams. A dirty platen will smudge paper. It is important to clean the printer regularly, paying particular attention to the printhead area and the paper paths.

If the lubrication procedures are not performed properly, the printer will require more frequent cleaning. Excessive lubricant attracts dust and accumulations build up quickly.

Keeping the covers in place and performing the cleaning procedures correctly will help ensure the highest quality printer output.

3.4.02 Cleaning Schedule

Routine inspection and cleaning should be performed:

1.every six months

or

2.every 300 hours of operating time.

3.4.03 Cleaning Tools

1. Clean, soft,

2.

3. Vacuum cleaner

4. Platen cleaner

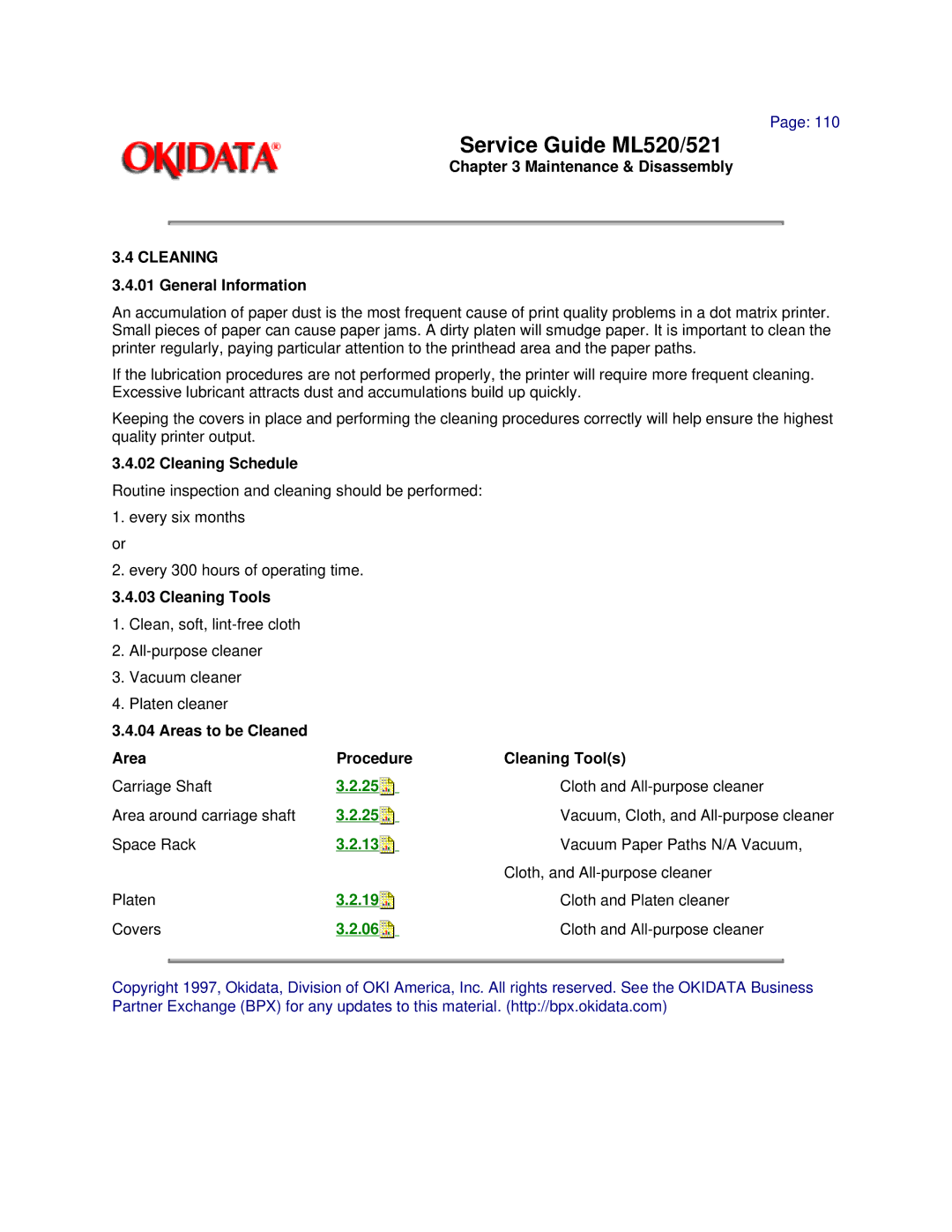

3.4.04 Areas to be Cleaned |

|

|

Area | Procedure | Cleaning Tool(s) |

Carriage Shaft | 3.2.25 | Cloth and |

Area around carriage shaft | 3.2.25 | Vacuum, Cloth, and |

Space Rack | 3.2.13 | Vacuum Paper Paths N/A Vacuum, |

|

| Cloth, and |

Platen | 3.2.19 | Cloth and Platen cleaner |

Covers | 3.2.06 | Cloth and |

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)