ML520 // ML521 Dot Matrix Printers

About This Manual

Service Guide ML520/521

Maintenance & Disassembly

Failure & Repair Analysis

Illustrated Parts Listing

Table of Contents

Service Guide ML520/521

Page

Product Specifications General Information

Printer Weight Microline

Microline

Product Specifications

Power Requirements

Ambient Temperature and Relative Humidity RH

Altitude

Product Specifications Agency Approvals 1.5.01 Listings

IPS

CPI CPS

Horiz. DPI Vert. DPI

HSD

UPC a UPC E EAN

Emulations

Front Panel Switches

Graphics Resolution

Fonts Near Letter Quality

Selects Group Function

Menu Mode Switch Action

Line Feed Increments Fixed

Form Feed / Load Selects Item

Paper Tear Capabilities

Paper Loading

Paper Out Detection

Print Method Printhead Type General Information

Auto Gap

Printhead Gap Adjustment

Gap Control

Semi Auto Gap

Print Modes

80 12 cpi 320 12 cpi 427 12 cpi

Continuous Form

Paper Specifications

Types Card Stock

Cut Sheet

Envelopes

Labels

Transparency

Number of Copies

Weight

Length

Thickness

Width

Paper

Printing Area

Eprom

Memory Specifications

Eeprom

03 RAM

Product Specifications Consumables 1.9.01 Ribbon

Dual Bin

Page

Product Specifications Pull Tractor Kit

Product Specifications Bottom Push Tractor Kit

Product Specifications Serial Interface

Product Specifications Roll Paper Stand

Product Specifications OKISmart Typer Utility

OKISmart Panel Utility

Reliability

Principles of Operation

Electrical Operation

Principles of Operation Main Control Board

Principles of Operation Block Diagram

Principles of Operation Program ROM

RAM

LSI

Service Guide ML520/521

Reset operation initiated by I-PRIME does not reset the MPU

Principles of Operation Initialization

Principles of Operation Parallel Interface Control

Principles of Operation Print Control

Principles of Operation LSI/Printhead Interface

Principles of Operation Gap Adjust Control

Principles of Operation Print Compensation Control

Also refer to .1.07 Head Drive Time

Service Guide ML520/521

Principles of Operation Line Feed Motor Control

Principles of Operation Space Motor Control

Principles of Operation Encoder Disk

Principles of Operation Operation Panel

Page

Service Guide ML520/521

Principles of Operation Low Motor Drive Voltage Alarm

Principles of Operation Head Drive Time

Less than 50%

+34 vdc or greater

Principles of Operation Head Overheat Alarm Processing

Principles of Operation Power Supply Circuit

Voltage/Signal Purpose

Service Guide ML520/521

Principles of Operation Printhead Gap Information

Page

Service Guide ML520/521

Principles of Operation Line Feed Motor Resistance

Principles of Operation Space Motor Resistance

Principles of Operation Printhead Operation

Page

Principles of Operation Printhead Temperature

Principles of Operation Spacing Mechanism

Principles of Operation Spacing Operation

Head Gap Setting Operation

Principles of Operation Head Gap Mechanism

Page

Principles of Operation Ribbon Drive Operation

Page

Principles of Operation Line Feed Mechanism

Change Lever Paper Path Selection Lever

Paper Clamp Mechanism

Page

Rear/Bottom Feed for continuous feed paper

Page

Principles of Operation Cut Sheet Paper Feed Operation

Service Guide ML520/521

Service Guide ML520/521

Service Guide ML520/521

Service Guide ML520/521

Rear Feed Detection

Bottom Feed Detection

Page

Principles of Operation Support Protector Mechanism

Principles of Operation Automatic Paper Load

Cut Sheet Paper

Principles of Operation Continuous Feed Paper

Principles of Operation Paper Park

Paper Park Operation

Maintenance & Disassembly General Information

Maintenance & Disassembly Maintenance Tools

Maintenance & Disassembly Maintenance Precautions

Handbook when the any of the following occur

Service Guide ML520/521

Maintenance & Disassembly Preliminary Items

Page

Maintenance & Disassembly Printhead Assembly

Perform this procedure

Page

Maintenance & Disassembly Ribbon Protector

Perform these procedures 3.2.01 ,

53562801 Protector Ribbon Rspl Both B.2.07

Maintenance & Disassembly Gear Case Assembly

Maintenance & Disassembly Pull-up Roller Assembly

When cleaning, refer to .4 of this Service Handbook

Page

Maintenance & Disassembly Control Board Fjim

Installation

Page

Maintenance & Disassembly Power Supply Assembly

Page

Maintenance & Disassembly Operator Panel PCB Leop

Perform these procedures 3.2.01 , 3.2.06 ,

Maintenance & Disassembly PC Connector

Perform these procedures 3.2.01 , 3.2.02 ,

56729601 Connector PC HD40 Rspl Both B.2.07

Perform these procedures 3.2.01 , 3.2.02 , 3.2.04 ,

Page

Maintenance & Disassembly Carriage Cable

Perform these procedures 3.2.01 , 3.2.06 , 3.2.07 ,

Maintenance & Disassembly Space Rack

When cleaning, refer to .4 of this Service Handbook

Page

Maintenance & Disassembly Roller/Holder Backup Assembly

Maintenance & Disassembly Guide Rail and Adjust Cam

Page

Maintenance & Disassembly Left Ground Plate

51010301 Plate Left Ground Rspl Both B.2.04

Maintenance & Disassembly Right Ground Plate

51010201 Plate Right Ground Rspl Both B.2.05

Perform these procedures 3.2.01 , 3.2.06 , 3.2.07 , 3.2.16 ,

Maintenance & Disassembly Platen Assembly

When lubricating, refer to .5 of this Service Handbook

Page

Maintenance & Disassembly Paper Chute Assembly

Page

Maintenance & Disassembly Line Feed Motor Assembly

56627201 Cord Connection Line Feed Rspl Both B.2.04

Maintenance & Disassembly Reset Spring

50923201 Spring Reset Rspl Both B.2.05

Maintenance & Disassembly Idle Gear and Change Lever

Page

Maintenance & Disassembly Pressure Spring

Page

Maintenance & Disassembly Carriage Shaft

Page

Maintenance & Disassembly Leaf Spring

Page

Maintenance & Disassembly Bottom Paper Sensor Levers

Page

Maintenance & Disassembly Front Pressure Roller Assembly

Page

Maintenance & Disassembly Tractor Assembly

Page

Page

Maintenance & Disassembly Main Frame

Service Guide ML520/521

Procedure Setup Phase

Printhead Gap Modification Phase

Parallel Adjustment Phase

Verification Phase

Page

Maintenance & Disassembly Key Combinations Description

SEL + FF/LOAD

Menu Mode

Printing the Menu

Reset Menu to Factory Defaults

Procedure

Limited Operation General Information

Page

Maintenance & Disassembly Menu Settings

Group Setting

Valid

Yes No

Page

Maintenance & Disassembly Top of Form General Information

Setting Top of Form

Reset the Top of Form to Factory Default

Maintenance & Disassembly Paper Park General Information

Procedure Continuous Feed to Single Sheet

Procedure Single Sheet to Continuous Feed

Maintenance & Disassembly Tear Feature

Maintenance & Disassembly Forms Tear Off

Vertical Line Spacing Problems

Using

Checking Top of Form with Form Tear Off Activated

Factory default Top of Form Setting is 1 inch

Cleaning Schedule

Maintenance & Disassembly

Cleaning

Cleaning Tools

Lubrication Types

Lubrication

Lubrication Schedule

Lubrication Amounts

Areas Not Lubricated

Return for Service

Shipping Instructions

All Other Returns

Failure & Repair Analysis Introduction

Service Guide ML520/521

Failure & Repair Analysis Firmware Revision Identification

Header

Service Guide ML520/521

Failure & Repair Analysis Problem Lists

Fax Number

Failure & Repair Analysis Reporting Methods Okilink

Course Critique

Mailing Address

Technical Service Bulletins

Okilink

Faxable Facts

Service Guide ML520/521

Operational Errors

Failure & Repair Analysis Problem Categories

Alarm Lamp Blinks Fatal Errors

Alarm Lamp Lights Paper End/Jam Conditions

Failure & Repair Analysis Start Here Flowchart

Start

Failure & Repair Analysis Tips for Preventing Image Problems

This Service Handbook

Failure & Repair Analysis Common Problems

Always power OFF the printer before you turn the platen knob

Page

Uneven Print Density

Smeared Print

Inconsistent Line Feed

Drifting Margin

Failure & Repair Analysis Left Margin Drifting Problem

Fault Alarms

Failure & Repair Analysis

Alar Utility PRO NLQ HSD Menu

Blinkin Kin

Refer to RAP

Page

Service Guide ML520/521

Failure & Repair Analysis RAP Index RAP Number Description

Start

Page

Failure & Repair Analysis RAP 02 No Spacing Operation

Page

Failure & Repair Analysis RAP 03 Printhead Homing Error

Page

Service Guide ML520/521

Failure & Repair Analysis RAP 05 Printhead Pins Not Firing

Failure & Repair Analysis RAP 06 Poor Print Quality

Failure & Repair Analysis RAP 07 Ribbon Feed Problem

Failure & Repair Analysis RAP 08 Line Feed Problem

Page

Failure & Repair Analysis RAP 09 Operation Panel Malfunction

Failure & Repair Analysis RAP 10 Parallel Interface Problem

Page

Failure & Repair Analysis RAP 11 Serial Interface Problem

Handbook

Printer Tests

Procedure

Page

Failure & Repair Analysis Font Test General Information

Page

Loopback Connector Configuration

Failure & Repair Analysis Serial Interface Loopback Test

Page

Failure & Repair Analysis Serial Cable Information

Service Guide ML520/521

Service Guide ML520/521

Example

Hex Data Dump

Service Guide ML520/521

Layout Diagram

Service Guide ML520/521

Failure & Repair Analysis Line Feed Motor Resistance

Failure & Repair Analysis Space Motor Resistance

Service Guide ML520/521

Chapter a Reference Charts

Description Board Designation Section Main Controller Board

Operator Panel Board

Chapter a Reference Charts Board Layout

Fuses

Switches

Firmware

Jumpers

Page

Shift

Page

Chapter a Reference Charts Power Supply Assembly Function

Page

Chapter a Reference Charts Space Motor Board Function

Page

Masked to the MPU Socket is empty

Page

Service Guide ML520/521

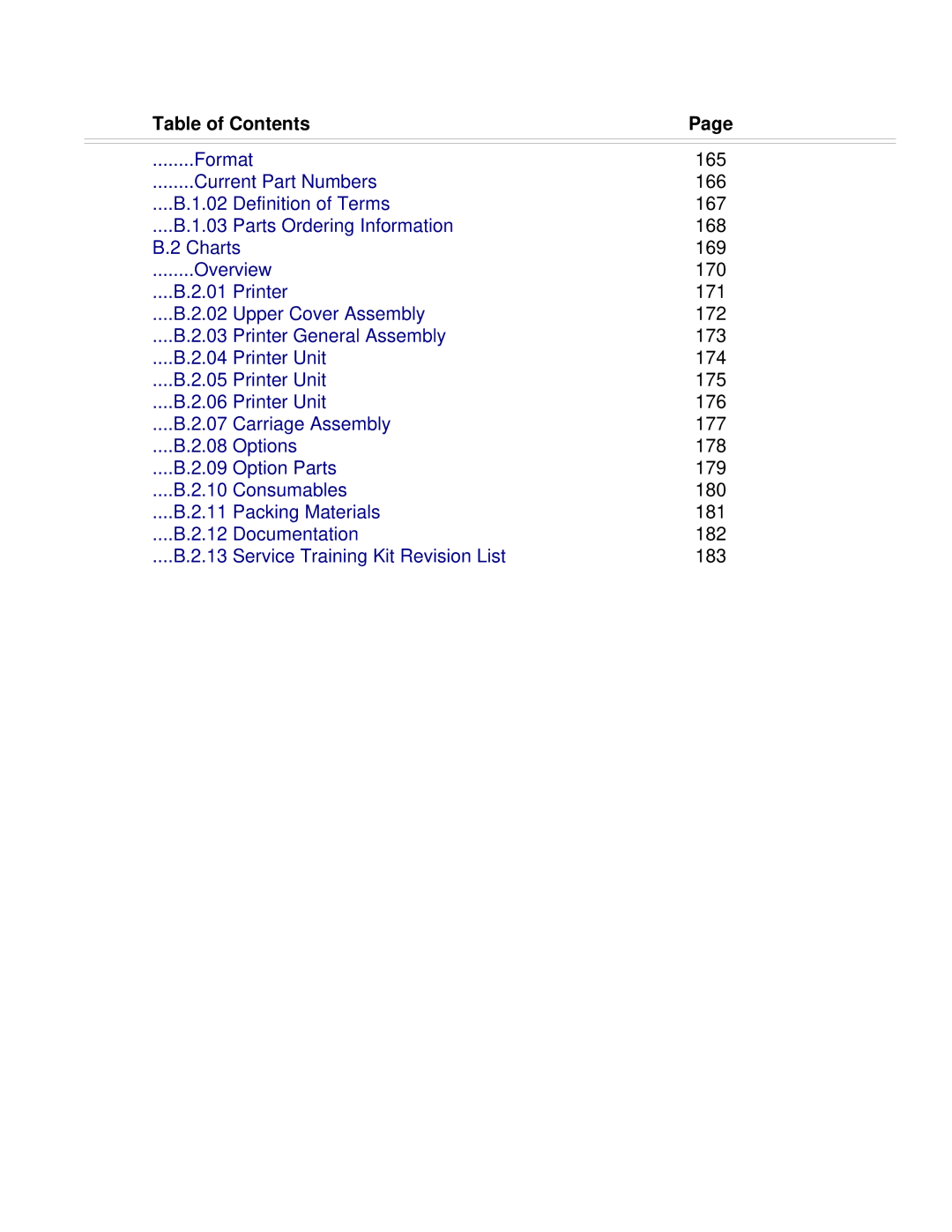

Chapter B Illustrated Parts Listing Format

Chapter B Illustrated Parts Listing Current Part Numbers

Remember

Rspl

520

521

Both

Placing a Parts Order

Charts

Chapter B Illustrated Parts Listing Overview

Comments

Refer to

Comments Refer to

53067201 2PA4094-7382G1 Cover Access Wide Rspl

ROM

PCB Leop

Service Guide ML520/521

Page

Service Guide ML520/521

Page

Service Guide ML520/521

Page

Page

Service Guide ML520/521

N/A

Service Guide ML520/521

PCB Lxhi

Service Guide ML520/521

PCB Ncsf

Chapter B Illustrated Parts Listing Consumables

52107001 N/A Ribbon Black Consumable Both

Comments Refer

To B.1.02

Service Guide ML520/521

Page

Okidata P/N Oki-J Description

Comments Refer

Comments Refer