OMB-483-0901 Rev

Portable Data Recorder

For immediate technical or application assistance

Servicing North America

Servicing Europe

Appendices

How To Use This Manual

Table of Contents

EZ-PostView and ViewXL Calibration

ChartScan User’s Manual

Overview

ChartScan Unit Startup and ChartView Tutorial

Inspect Your System

Unit Startup

Selection Micro Setting Switch #

Verify Voltage Setting

Verify DIP Switch Setting

Install Signal Conditioning Cards

Connect Expansion Chassis option

Install Ieee 488 Interface Communications Card option

Error Condition LED Indicators

Apply Power to ChartScan

DB50 Pin Descriptions

Start ChartView, Configure System, and Collect Data

� = Mouse, Ú= Arrow Keypads , � = PageUp/PageDown Keypads

ChartView Main Window Control Options

Device Interface

Configuration Files

ChartView, Basic Concepts

Acquiring Data with no charting or meter use

ChartView Tutorial

Select Interface Device

Advanced

Moderate

Configure Channels & Alarms

Configure Acquisition

Count

High Speed Setup

Parameter Options

Stop

Review Configuration

Page

ChartScan User’s Manual

General Description

General Information

Data Handling and Triggering

Operational Aspects

Software and Hardware

ChartScan Specifications

Channels

General

Data Storage & Format

Triggers

Digital I/O Interface & Alarms

Calibration

− Notes

Front Panel

Hardware

Rear Panel

Changing the Voltage Setting

Power Aspects

Replacing the AC Power Supply Fuse

Memory Configuration

Expanded Memory Options

Memory Option JP201 JP202

Calibration Memory Write Enable/Disable

RS-232/422 Interface Configurations

Configuring RS-232/422 Parameters

Standard Units, Only

Selection Micro Setting Switch

Early Production Units, Only

Pin # RS-232 Signal Pin Description

Serial Port Pin Connectors

ChartScan to PC Connection RS-232 DB9 Male Pin & Signal

Cable Wiring DB9 Female Pin & Signal

Ethernet Interface Configuration

Specifications

Ieee 488 Interface Configuration Option

Ieee 488 Pinout

Ieee 488 Configuration

Ieee 488 Configuration Settings

Logic Levels

Digital I/O Lines

Digital I/O Port Pinout

Signal Conditioning Cards

External TTL BNC Connectors

Fault Detection

Input Connector

Temperature Range, Accuracy, and Resolution1 Type J

Temperature Units

Digital Filtering

Voltage Range2, Accuracy3 and Resolution

CSN14/LV/ T, B, & S Low Voltage Cards

Voltage Range, Accuracy1 and Resolution

Voltage Range, Accuracy and Resolution

Input Connectors

Number of Inputs

Slot

Device

Connecting the Expansion Chassis

CSN/Relay Card Specifications

Expansion Chassis, CSN/Exp Option

Cross Section of Mounting Block

Device Channel Assignments Slot

Automatic Channel Assignment

Number of Slots Four

Channel-to-System Isolation 500 V peak Dimensions

− Notes

ChartView Software Reference

Three Ways of Using ChartView

Groups, Charts, & Channels

Waiting for Trigger

What ChartView and ChartView Plus Provide

Main Window

ChartView Main Window and Control Options

Channel Information Region

Instrument

Status Indicator Region

Scroll Faster Scroll Slower

Start, Pause, Stop Charts

Main Window Toolbar

Group Select

Normal Edit

Display Configuration

ChartView Software Reference ChartScan User’s Manual

Adjusting Channel Setup for Channel

Manually Creating a Display

Adding a Chart to Group

Adjusting Channel Setup for Channel

Disarm

Channel Configuration

PostView post-acq data viewer

Arm Acquisition

See File Menu Note, immediately following this text

Print Charts

Main Window Pull-Down Menus

File

File Menu Note

Chart

View

Display config

System

Charts

Acquisition

Data

Acquire

Displays the condition of a data acquisition

Ctrl + J manual control

Command Characters Data Destination Timeout Region

Ctrl + U manual

Window

Setup

Device …

Log configuration

ChartScan User’s Manual ChartView Software Reference

Device Expanded Menu obtained with use of the F12 Key

Log Enable

Ctrl+A

Bar Graph, Analog, and Digital Meters

Setup

Overview

Bar Graph Meters

Configuration Note

…. for Analog Meters

Analog Meters

…. For Digital Meters

Digital Meters

Name Function

Reset. This feature does not apply to the Digital Meters

Meter Toolbars

Meter Pull-Down Menus

Configuring a Meter

Meters Configuration Menu

Channel & Alarm Setup Dialog Box

Setup Window

Configure Meter Settings, Function Descriptions

Channel and Alarm Setup, Button Descriptions

Example

Channel Configuration Columns

Alarm Configuration Columns

Acquisition Setup Dialog Box

Acquisition Setup Dialog Box, Normal Mode

Normal Mode, CH1 and CH2 Assigned to a Chart

Burst Mode, Operational Issues

Introduction

Measuring AC Voltage, or AC RMS Voltage

Measuring AC RMS

Data Destination

Data Destination Dialog Box

Why use Auto Re-arm?

Introduction

Chart Setup Wizard

Chart Setup Wizard, Simple Mode

Automatic Chart Setup with Wizard

Bypassing Automatic Chart Setup

EZ-PostView

Introduction

ViewXL

EZ-PostView includes the following features

Reference Note

Range 100 mV

Calibration Setup

Range

Hardware Protected RAM

Non-Volatile Storage of Calibration Constants

Instruction Tool Icon

Using ScanCal

ScanCal Software Application

ScanCal’s Main Window

System Inventory

Interface Parameters

Calibration Without ScanCal

Password

Mode Indicator

Command Active Indicators

Offset Calibration of Main Unit

Calibration of Main Unit

Required Equipment

U132

U128

U129

U130

Gain Calibration of Main Unit

U128

Offset Calibration of Cards

Calibration of Signal Conditioning Cards

Cal Err offset, gain, or temperature sensor out of range

Gain Calibration of Low Volts Cards

ChartScan User’s Manual Calibration

Volts DC Slot #

…to clear the buffer

#1X QC?

C1,1X

Gain Calibration of High Volts Cards

…to clear the buffer

Option c T/C Calibrator/Simulator Method

Cold Junction Calibration

Option a Cold Cell Method

Option b Hot Cell Method

Calibration ChartScan User’s Manual

Enter J3,3,0000.0X J6,3,0000.0X J11,3,0000.0X J14,3,0000.0X

Calibration ChartScan User’s Manual

Appendices

ChartScan User’s Manual

Appendix a

Contents

Command Syntax

Fixed Formats

Command Interpretation

Conflict Errors

Immediate & Deferred Commands

Command Type

Order Function

Deferred Commands, Order of Execution

Command Summary

E002

#make

E000

E001

Mmask

Lchan

Level

Hyst Chan max

Tstart

Rtype

#chans

Stime

− Notes

Type

Command Reference

Command Description Format

Commands

Sleep

Trigger On Command

PRINT#1, OUTPUT07T1,1,0,0X

PRINT#1, OUTPUT07 @X

PRINT#1,OUTPUT07 *BX

Flush Acquisition Buffer

PRINT#1,SPOLL07

INPUT#2, S%

Channel

Clear Channel Configuration

‘ Clear all channels configuration

PRINT#1,OUTPUT07

Input A$

Restore Factory Settings

PRINT#1,OUTPUT07Q?T?Y?X

PRINT#1,ENTER07

PRINT#1, ENTER07 INPUT#2, C%

If C% and 16 then PRINT,ERROR-INVALID Keyword Sleep

Change Calibration Keyword

PRINT#1, OUTPUT07U2X

PRINT#1,OUTPUT07*P01X

Adjust Calibration Card Pots

PRINT#1,OUTPUT07K12345X

PRINT#1,OUTPUT07*P02X

Print #1, SPOLL07

Power-On Reset

PRINT#1,OUTPUT07*RX

While S% and 4 =

PRINT#1, OUTPUT07*RX

Power-Up Settings

‘ Screen shows Q1,7,7,7,0 T1,3,0,0 Y000100

PRINT#1,OUTPUT07*S1X

PRINT#1,OUTPUT07*T0X

Time Stamping

PRINT#1,OUTPUT07*T1X

PRINT#1,OUTPUT07*T2X

Assign Alarm Output

Byte 1 A07 A00 Byte 2 A15 A08 Byte 3 A23 A16 Byte 4 A31 A24

# Alarm Stamping

PRINT#1,OUTPUT07A#1X

PRINT#1,OUTPUT07A#0X

Configure Channels

Volts Card Types

Same as Without temperature Temp

Thermocouple Card Types

These special types are valid only in degrees Celsius

PRINT#1,OUTPUT07X

PRINT#1, OUTPUT07*C

PRINT#1,OUTPUT07 U13X

# Select Card

PRINT#1, OUTPUT07D#12X

Set Relay Make Time

PRINT#1, OUTPUT07M#0X

PRINT#1, OUTPUT07W#32X

PRINT#1, OUTPUT07J1,2,90.0X

End Calibration Mode

PRINT#1, OUTPUT07H17X

PRINT#1, OUTPUT07G17,1X

PRINT#1,ENTER07 INPUT#2,A$ Print A$

? Error Status Query

PRINT#1,CLEAR07

PRINT#1,OUTPUT07E?X

Data Input Formats see Note

Set Data Format

Dddddddd =

Data Output Formats

MM/DD/YY

Dddddddd

PRINT#1, ENTERO7

PRINT#1, OUTPUT07F0,0X

PRINT#1,OUTPUT07C1, 1

PRINT#1, OUTPUT07 U4X

OUTPUT07F#100.5X

# Set Burst Mode Frequency

PRINT#1

OUTPUT07F#15000.0X

PRINT#1, OUTPUT07G17,1

Calibrate Channel Gain

Calibrate Channel Offset

PRINT#1, OUTPUT07I010000.0

Set Scan Interval

Inorm

Acq

PRINT#1, OUTPUT07I#1X

Digital Input Stamping

PRINT#1, OUTPUT07I#0X

PRINT#1, OUTPUT07R1X

Temp

Calibrate Cold Junction Offset

PRINT#1, OUTPUT07J1,2,101.7X

If C% and 16 then

Enter Calibration Mode

PRINT,ERROR-INVALID Keyword Halt

Print #1, ENTER07 INPUT#2, C%

PRINT#1, OUTPUT07T4,5,0,0X

Set Trigger Level

Hyst

PRINT#1, OUTPUT07F0,0X PRINT#1, OUTPUT07L1,100.0,10.0X

Set SRQ Mask

PRINT#1, OUTPUT07M#1X

Set Measuring Mode

Set Event Mask

PRINT#1, OUTPUT07O?X

Set Digital Outputs

PRINT#1 OUTPUT07O?X

Line Input #2, N$ Print N$

Program Trigger Times

PRINT#1, OUTPUT07 V4 V?

? Query

OUTPUT07 V1 X V?

PRINT#1, OUTPUT07 V0 X V?

None

Set Query Terminator

CR LF/EOI LF CR/EOI USER/EOI User

Terminator Type Terminator Description IEEE-488

PRINT#1,OUTPUT07Q?X

R1X R2X R3X

U4X U5X

PRINT#1,OUTPUT07F0,0X

INPUT#1 PRINT#1

QC? Query Card Data

PRINT#1, OUTPUT07 C#5X

PRINT#1, OUTPUT07 QC?X

API Commands Appendix a

PRINT#1,ENTER07 Line INPUT#2, A$

Read Buffered Data

While S% and 8 =

PRINT#1 SPOLL07 INPUT#2, S% Wend PRINT#1,OUTPUT07R1X

Line Input #2, R$ Print R

# Read Last Readings

PRINT#1,OUTPUT07F1,0X

PRINT#1,OUTPUT07R#16X

PRINT#1, OUTPUT07 S140000.0,4/30/93X

Set Real Time Clock

Set Trigger Configuration

PRINT#1, OUTPUT07T1,7,0,1X

PRINT#1, OUTPUT07

000100.0X

PRINT#1, OUTPUT07Y100,10000,0X

User Status

?I?L?P?Q?S?T?Y?

#123101.20,04/24/93

00256

01024

001,1,002,0,003,0 …

Change Calibration Keyword

PRINT#1, OUTPUT07V58X

Set User Terminator

PRINT#1, OUTPUT07V44X

PRINT#1,OUTPUT07@X

PRINT#1, OUTPUT07C1

# Set Average Weight

PRINT#1, OUTPUT07W#64X

OUTPUT07Y0,10,0X

C18-32,3

Execute

PRINT#1,OUTPUT07*C

PRINT#1,OUTPUT07C1-16,1 C17,2

PRINT#1,SPOLL07 INPUT#2,S% Wend PRINT#1,OUTPUT07U6X

Set Counts, or Select Blocks

PRINT#1,OUTPUT07N0 N2

PRINT#1,SPOLL07 INPUT#2,S% Wend PRINT#1,OUTPUT07N0 N1

Appendix B

Memory Allocation

U16

Measuring Modes

U17

Scan time = #channels x #samples/channel + 12 x 520.83 µs

Normal Mode

‘Select Normal mode #16 Samples over which to average

‘Select Normal mode Sample over which to average

‘Select high-speed, single-channel mode

High-Speed, Single-Channel Mode Burst Mode

Condition

PRINT#1,OUTPUT07 U4X

Configuration Requirements

Signal-Conditioning Modules Type Inputs Connector

Channel Configuration

Type Volts AC

CSN14/TC/P Configuring Thermocouple Channels

CSN14/LV/ T, B, or S Configuring Low Volts Channels

Type Volts DC

Configuring the Scan Interval

Scan Configuration

CSN14/HV/S Configuring High Volts Channels

Configuring a Scan

I000010.0,000000.0

Acquisition Configuration

Component Description Required

I000010.0,000000.1

Continuous, Gap-Free Acquisition with Two Timebases

Pre-Trigger State

Configuration Aspects for Programmers Appendix B

Post-Trigger State

Trigger and Stop Events

Post-Stop State

‘@’ character

Selected Temperature Channel High or Low Level

Alarm on or off

External TTL High or Low Level

Time Stamping *T

Alarm Stamping A#

Digital Input Stamping I#

With Alarm Stamping

PRINT#1, OUTPUT07A#1X

With Digital Input Stamping

‘ Enable digital input stamping

Get the response

Acquisition Buffer, a Description

Trigger Block Organization

PRINT#1,ENTER

PRINT#1,OUTPUT 07 U6X

PRINT#1,OUTPUT 07R1X

Multiple Trigger Blocks

Acquisition Buffer Interrogation

Field Response Implication

Field Response Implication

Print

Reading the Acquisition Buffer

PRINT#1,OUTPUT07 U6X

Input

PRINT#1,OUTPUT07R3X

PRINT#1,OUTPUT07R2X

Print #1

Configuring Alarms

Alarm Set Points

Digital Alarm Outputs

Set Point Hysteresis

PRINT#1,OUTPUT07A3,0X ‘Disable channel 3 from digital output

Digital I/O Operation

Appendix C

HLL Register Contents

Using High/Low/Last HLL Registers

Accessing HLL Registers

Example

Example shows how to read only the Last readings

Data Format F

Data Format F

Data Input Formats

Code

Thermocouples

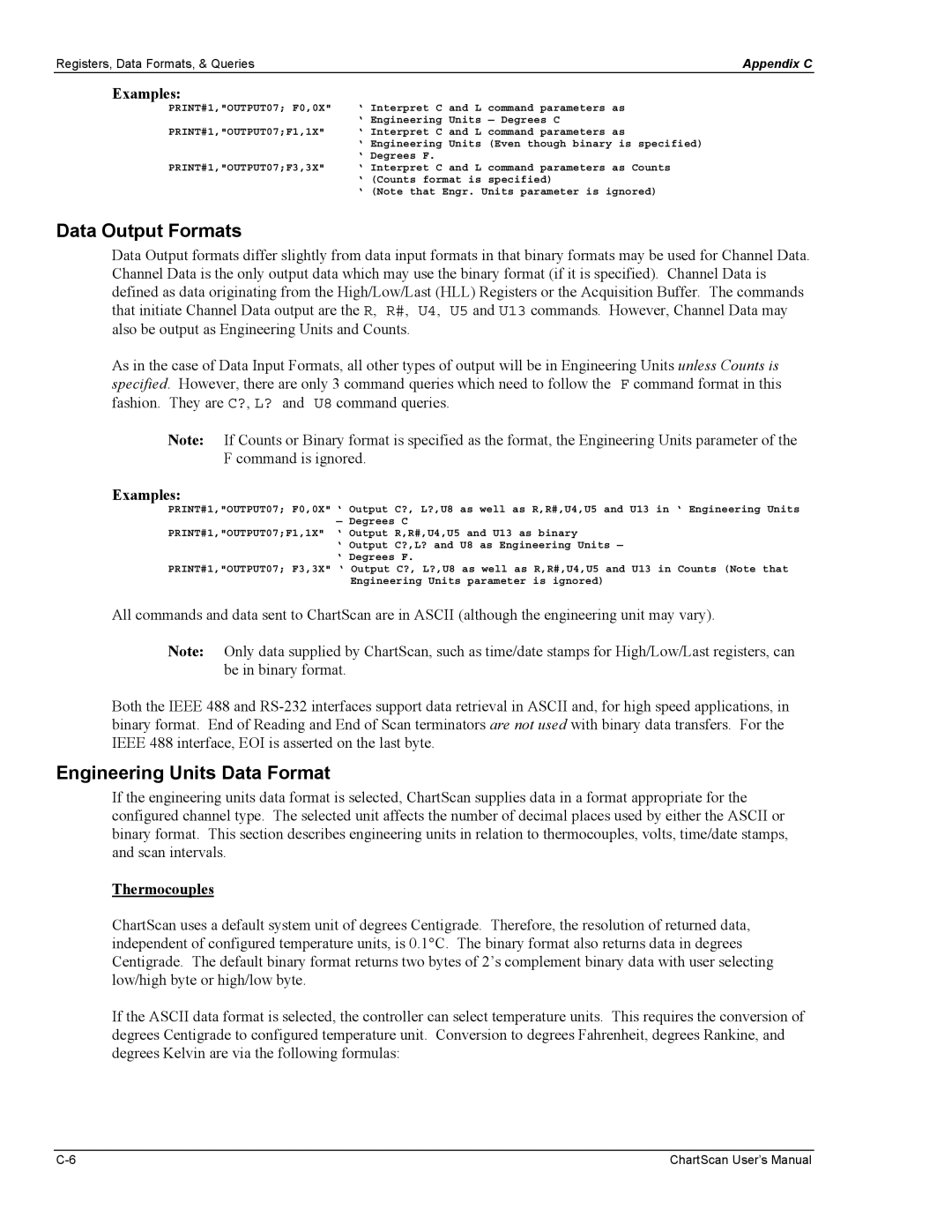

Data Output Formats

Engineering Units Data Format

Examples

Time/Date Stamp

Volts

Hhmnss.t,mm,dd,yy

HHhmstMDYLLhmstMDYll

Binary Data Format

Counts Data Format

010203.5

Configuring Power-Up State

Queries

Query ? Commands

Status Commands

Vuser where 0 user

Status, Event Reporting, and Mask Registers

Theory of Operation

Register Chart Status and Event Reporting Registers

Register Access

Register Chart Mask Registers

Appendix C Registers, Data Formats, & Queries

Event Status Register

Calibration Status Register U2 Command

Error Source Register E? Command

Event Status Enable Register

Bit Location Value Description

Status Byte Register

Ieee 488 Serial Poll Response

Service Request Enable Register

DIO8 MSBit

DI02

Using Status Reporting Registers

Avg

Trigger Latency

Trigger Overrun

Buffer Overrun

Buffer Overrun With Multiple Trigger Blocks

Open Thermocouple/Range Error Checking

Real Time Clock

Buffer Overrun With One Trigger Block

− Notes

Appendix D

ChartScan Program Examples

Reading HLL Data from T/C & Volts Cards using HLL32.BAS

Reading HLL Status using HLL16.BAS

Print #1, Output 07I000001.0,00000.3X

CLS Print The ChartScan is resetting

Print #1, Output 07C1-16,1X Print #1, Output 07C17-32,2X

Print #1, Output 07Y30,1,200X

PRINT#1, Enter INPUT#2, READING$

While INKEY$ = ‘’

Print #1, ENTER07 Output #2, U%

Print #1, Output 07L1,20.0,0X T4,5,0,0X

Print #1, Output 07C1-16,3X Print #1, Output 07C17-32,2X

Print #1, Output 07Y50,100,200X

Print #1, Output 07I000000.1,000000.1X

Operating Alarms using ALARM2.BAS

END if Wend

Print #1, Enter 07 Line Input #2, A$ Print A$

Else

END if

Print #1, Output 07M1X

Using the Ieee 488 SRQ with Alarms using ALAR2SRQ.BAS

On PEN Gosub AlarmHandler

PEN on Print #1, ARM SRQ

Line Input #2, A$

Collecting Data in Binary Format using BINACQ.BAS

Locate

Input #2 Print #1 Output 07O?X

Print #1, Output 07R2X

Print #1, Enter 07 Line Input #2, U$ Print U$

Binary DATA%/10 = C

Print #1, Output 07C1-16,1X Print #1, Output 07C17-32,14X

Collecting Binary-Formatted HLL Data using BINHLL.BAS

Print #1, Clear Print #1, Output 07*S1X

Print #1, Output 07M#0X Print #1, Output 07W#32X

Print STR$VALLAST$ Else

Decode received data and print on screen in Ascii

Print #1, Output 07Q,0,0,8,8,0X

Print #1, Output 07Y1000,20,10X

Print #1, Output 07I000000.3,000000.0X

Print #1, Output 07T1,8,1,0X

Print UA$

Print #1, Output 07U6X

Loop Until UA$=

Print UAT$

Wend Close END

While INKEY$ =

Print #1, Disarm SRQ

Sleep Print #1, ARM SRQ Return

Input #2, EVENT%

Print UA

Print #1, Output 07R3X

Print #1, Output 07C1,14x

Print #1, Output 07M#1X Print #1, Output 07F#20000.0X

Print #1, Output 07Y0,8,0X

Print SCAN$

Print #1, Output 07V32X Q7,0,7,7,1X

For i = 1 to UA% Print #1, Enter

Locate 14, 1 Print Scan i is

Appendix E

− Notes

Box Items

Universal Command Group UCG

Appendix F

Decimal Values 00 to 63 ACG, UCG & LAG

$41

Decimal Values 64 to 127 TAG & SCG

Ascii Code Details

Decimal Values 00 to 31 ACG & UCG Characteristics

Decimal Values 00 to 31 ACG & UCG Descriptions

Dec Name Description Addressed Command Group ACG

Ascii Control Codes 00 to

Space

Decimal Values 32 to 63 LAG

Decimal Values 64 to 95 TAG

Ascii Code SummaryAppendix F

Delete Command

Decimal Values 96 to 127 SCG

DEL

− Notes

Appendix G

LED Indications of Error Conditions LED Indicators

ChartScan Error Messages

Appendix H

Abbreviations Appendix H

Index

ChartScan User’s Manual

WARRANTY/DISCLAIMER

Temperature