2.Loosen lock knob and raise or lower upper blade guide assembly to approximately 3/16” above the material being cut.

3.Tighten lock knob.

4.The guide post (Figure 46) is spring loaded. To adjust the tension on the spring, unscrew and completely remove knob, then tighten or loosen set screw, until desired tension is reached.

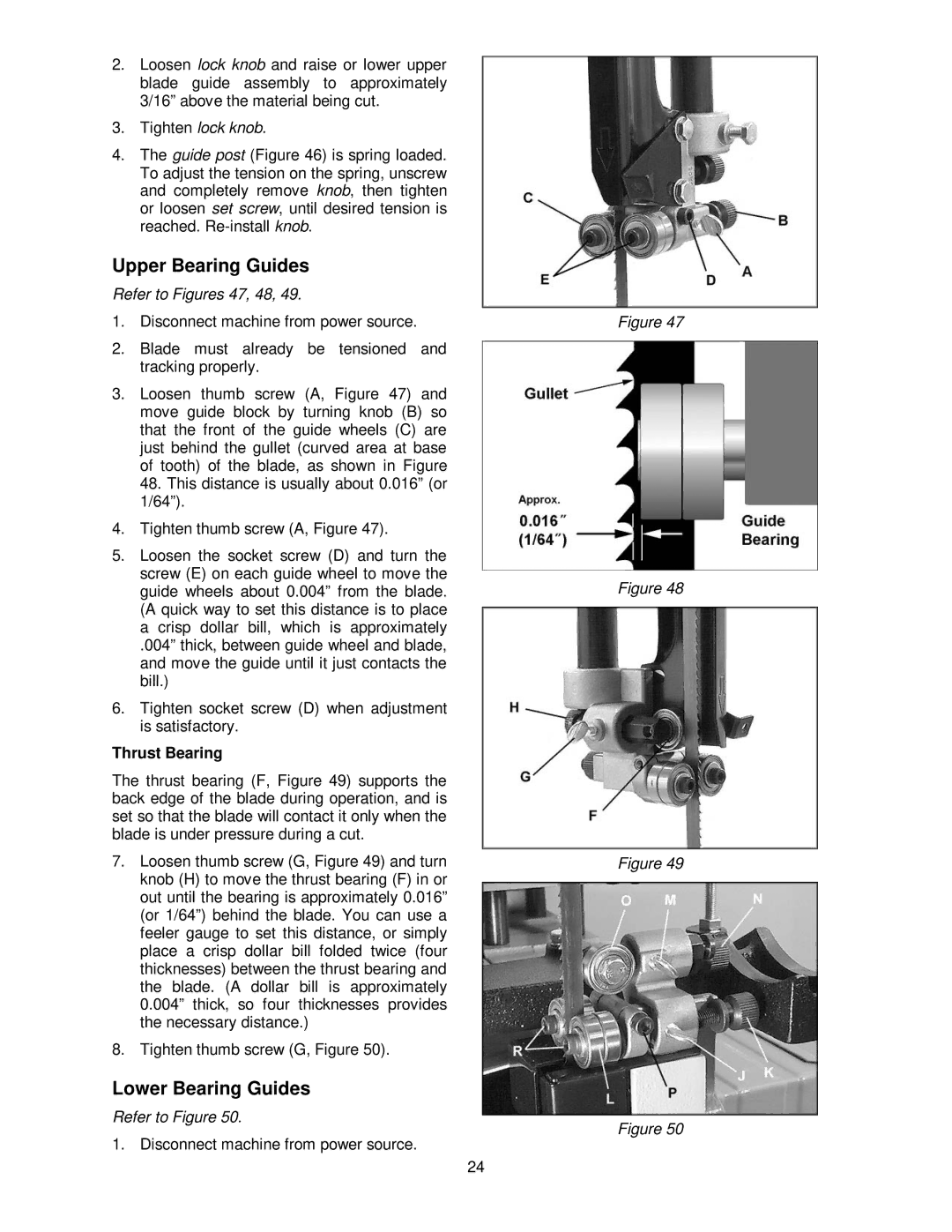

Upper Bearing Guides

Refer to Figures 47, 48, 49.

1.Disconnect machine from power source.

2.Blade must already be tensioned and tracking properly.

3.Loosen thumb screw (A, Figure 47) and move guide block by turning knob (B) so that the front of the guide wheels (C) are just behind the gullet (curved area at base of tooth) of the blade, as shown in Figure 48. This distance is usually about 0.016” (or 1/64”).

4.Tighten thumb screw (A, Figure 47).

5.Loosen the socket screw (D) and turn the screw (E) on each guide wheel to move the guide wheels about 0.004” from the blade. (A quick way to set this distance is to place a crisp dollar bill, which is approximately

.004” thick, between guide wheel and blade, and move the guide until it just contacts the bill.)

6.Tighten socket screw (D) when adjustment is satisfactory.

Thrust Bearing

The thrust bearing (F, Figure 49) supports the back edge of the blade during operation, and is set so that the blade will contact it only when the blade is under pressure during a cut.

7.Loosen thumb screw (G, Figure 49) and turn knob (H) to move the thrust bearing (F) in or out until the bearing is approximately 0.016” (or 1/64”) behind the blade. You can use a feeler gauge to set this distance, or simply place a crisp dollar bill folded twice (four thicknesses) between the thrust bearing and the blade. (A dollar bill is approximately 0.004” thick, so four thicknesses provides the necessary distance.)

8.Tighten thumb screw (G, Figure 50).

Lower Bearing Guides

Refer to Figure 50.

1. Disconnect machine from power source.

Figure 47

Figure 48

Figure 49

Figure 50

24