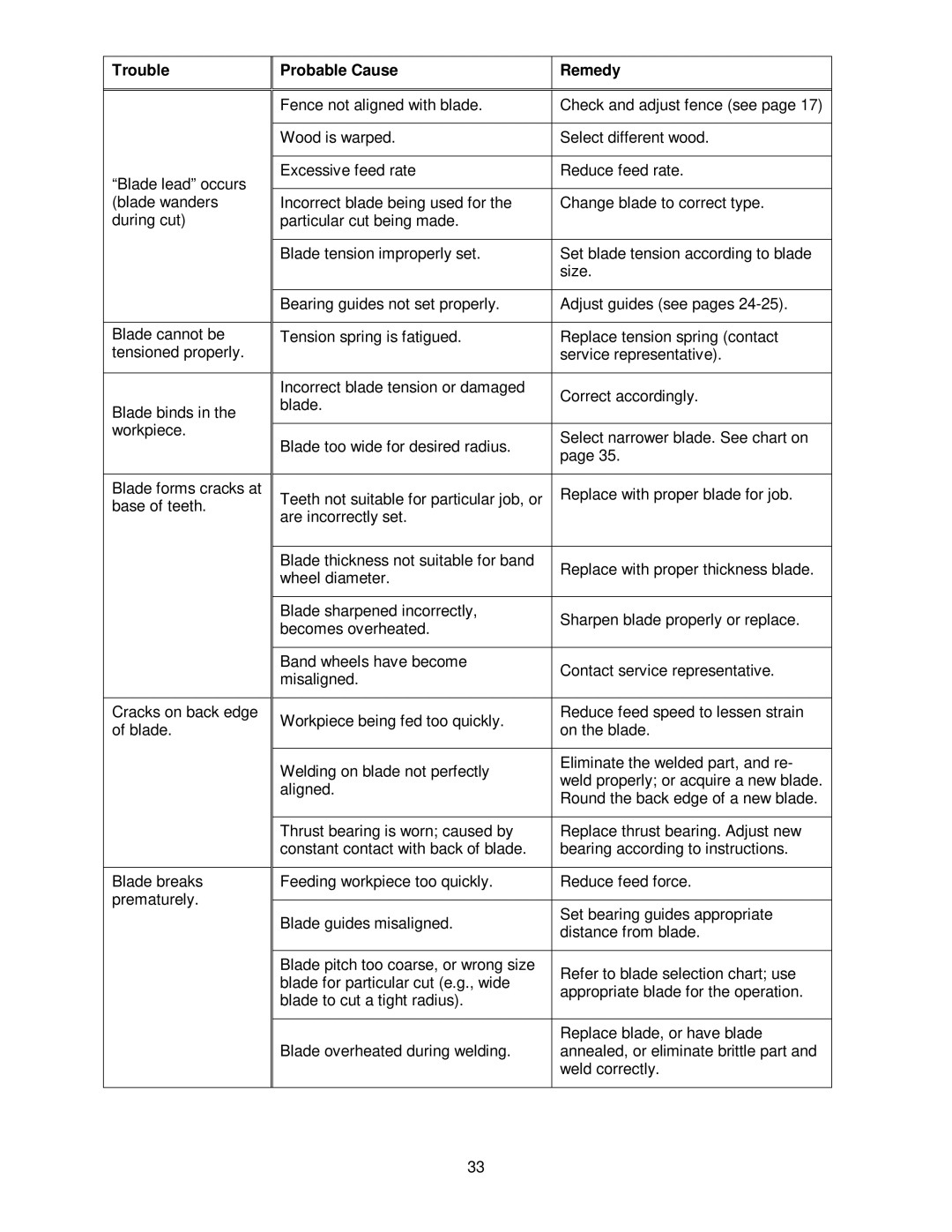

Trouble

“Blade lead” occurs (blade wanders during cut)

Blade cannot be tensioned properly.

Blade binds in the workpiece.

Blade forms cracks at base of teeth.

Cracks on back edge of blade.

Blade breaks prematurely.

Probable Cause | Remedy | |

|

| |

Fence not aligned with blade. | Check and adjust fence (see page 17) | |

|

| |

Wood is warped. | Select different wood. | |

|

| |

Excessive feed rate | Reduce feed rate. | |

|

| |

Incorrect blade being used for the | Change blade to correct type. | |

particular cut being made. |

| |

|

| |

Blade tension improperly set. | Set blade tension according to blade | |

| size. | |

|

| |

Bearing guides not set properly. | Adjust guides (see pages | |

|

| |

Tension spring is fatigued. | Replace tension spring (contact | |

| service representative). | |

|

| |

Incorrect blade tension or damaged | Correct accordingly. | |

blade. | ||

| ||

|

| |

Blade too wide for desired radius. | Select narrower blade. See chart on | |

page 35. | ||

| ||

|

| |

Teeth not suitable for particular job, or | Replace with proper blade for job. | |

are incorrectly set. |

| |

|

| |

Blade thickness not suitable for band | Replace with proper thickness blade. | |

wheel diameter. | ||

| ||

|

| |

Blade sharpened incorrectly, | Sharpen blade properly or replace. | |

becomes overheated. | ||

| ||

|

| |

Band wheels have become | Contact service representative. | |

misaligned. | ||

| ||

|

| |

Workpiece being fed too quickly. | Reduce feed speed to lessen strain | |

on the blade. | ||

| ||

|

| |

Welding on blade not perfectly | Eliminate the welded part, and re- | |

weld properly; or acquire a new blade. | ||

aligned. | ||

Round the back edge of a new blade. | ||

| ||

|

| |

Thrust bearing is worn; caused by | Replace thrust bearing. Adjust new | |

constant contact with back of blade. | bearing according to instructions. | |

|

| |

Feeding workpiece too quickly. | Reduce feed force. | |

|

| |

Blade guides misaligned. | Set bearing guides appropriate | |

distance from blade. | ||

| ||

|

| |

Blade pitch too coarse, or wrong size | Refer to blade selection chart; use | |

blade for particular cut (e.g., wide | ||

appropriate blade for the operation. | ||

blade to cut a tight radius). | ||

| ||

|

| |

| Replace blade, or have blade | |

Blade overheated during welding. | annealed, or eliminate brittle part and | |

| weld correctly. | |

|

|

33