| INSTALLATION |

|

|

| ||

| For USA installations follow local codes and/ | The manifold pressure is controlled by a regulator | ||||

| built into the gas control, and should be checked | |||||

| or the current National Fuel Gas Code, ANSI | |||||

|

| Canada | USA | at the pressure test point. | ||

|

| Z223.1. | ||||

INSTALLATION | Altitude | 0 - 2000 ft | 0 - 2000 ft | When using copper or flex connectors use only | Note: To properly check gas pressure, both | |

| (0 - 610m) | (0 - 610m) | ||||

|

| inlet and manifold pressures should | ||||

Min. Supply | 5" WC (1.25 | 5" WC | approved fittings. Always provide a union so |

| ||

| that gas lines can be easily disconnected for |

| be checked using the valve pressure | |||

| Pressure | kpa) | (1.25 kpa) | servicing. Flare nuts for copper lines and flex |

| ports on the valve. |

| Low Setting Man. | 1.6" WC | 1.6" WC | connectors are usually considered to meet this | 1) Make sure the valve is in the "OFF" | |

| Pressure | (0.39 kpa) | (0.39 kpa) | requirement. | ||

|

| position. | ||||

| Max. Manifold | 3.5" WC | 3.5" WC |

|

| |

|

|

|

| |||

| Pressure | (0.87 kpa) | (0.87 kpa) |

| 2) Loosen the "IN" and/or "OUT" pressure tap(s), | |

| Orifice Size | #33 DMS | #33 DMS |

|

| turning counterclockwise with a |

| Minimum Input | 22,000 Btu/h | 22,000 |

|

| 1/8" wide flat screwdriver. |

|

|

|

| |||

|

| (6.45 kW) | Btu/h |

| 3) | Attach manometer to "IN" and/or "OUT" |

|

|

| (6.45 kW) |

| ||

|

|

|

|

| pressure tap(s) using a 5/16" ID hose. | |

|

|

|

|

|

| |

| Maximum Input | 33,000 Btu/h | 33,000 |

| 4) | Light the pilot and turn the valve to "ON" |

|

| (9.67 kW) | Btu/h |

| ||

|

|

| (9.67 kW) |

|

| position. |

| Altitude |

| 5) | The pressure check should be carried out | ||

|

| ft. | ft. |

| ||

|

|

|

| with the unit burning and the setting should | ||

|

| (610- |

|

| ||

|

|

|

| be within the limits specified on the safety | ||

|

|

| 1371m) |

|

| |

|

|

| IMPORTANT: Always check for gas leaks |

| label. | |

| Orifice Size | #33 DMS | # 34 DMS |

| ||

| with a soap and water solution or gas leak | 6) | When finished reading manometer, turn off the | |||

| Minimum Input | 22,000 Btu/h | 21,500 | detector. Do not use open flame for leak | ||

| testing. |

| gas valve, disconnect the hose and tighten the | |||

|

| (6.45 kW) | Btu/h |

| ||

|

|

|

| screw (clockwise) with a 1/8" flat screwdriver. | ||

|

|

| (6.30 kW) |

|

| |

|

|

|

|

| Note: Screw should be snug, but do not | |

| Maximum Input | 33,000 Btu/h | 32,000 |

|

| |

|

|

| over tighten. | |||

|

| (9.67 kW) | Btu/h |

|

|

|

|

|

| (9.37kW) |

|

|

|

|

|

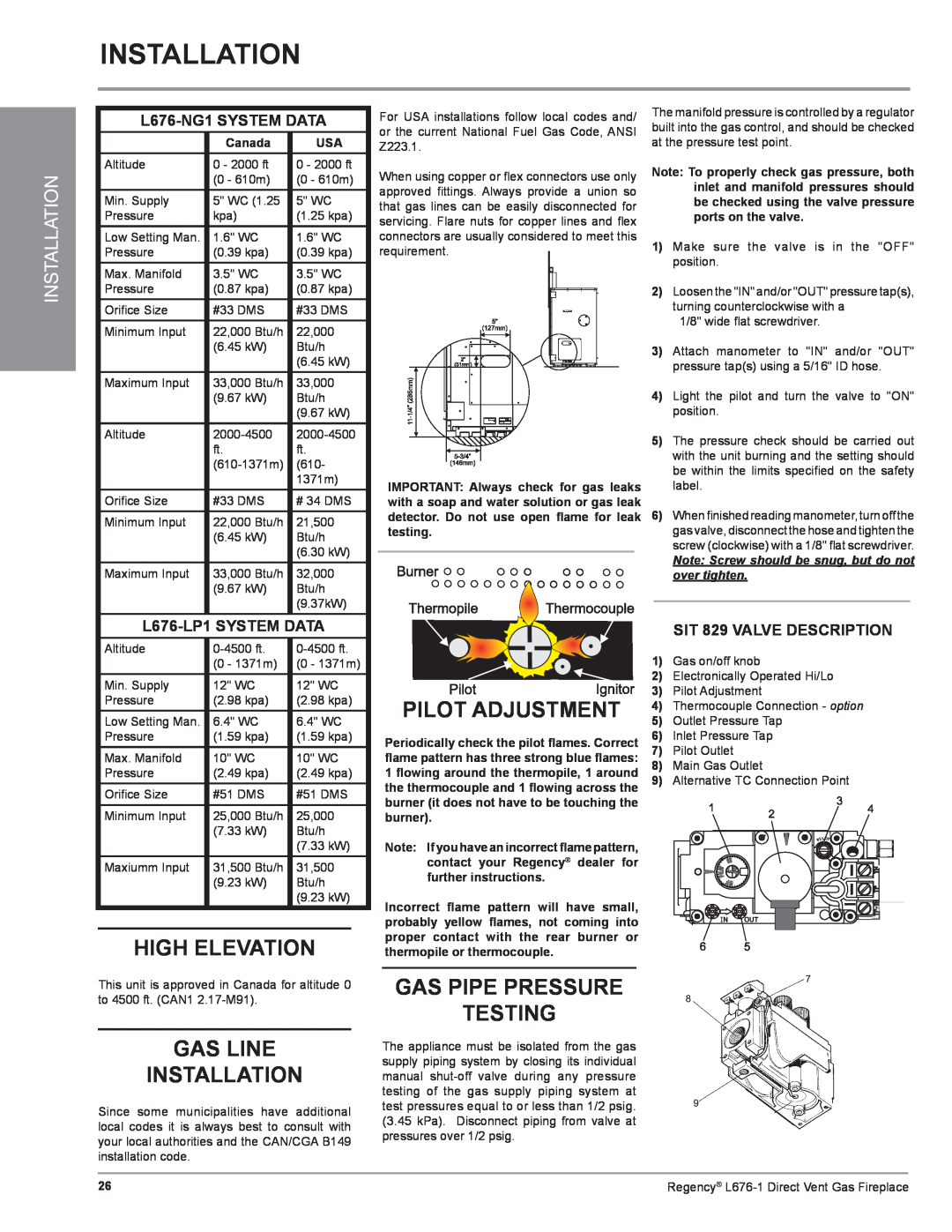

| SIT 829 VALVE DESCRIPTION | |||

| Altitude |

| 1) | Gas on/off knob | ||

|

| (0 - 1371m) | (0 - 1371m) |

| ||

| Min. Supply | 12" WC | 12" WC |

| 2) | Electronically Operated Hi/Lo |

|

| 3) | Pilot Adjustment | |||

| Pressure | (2.98 kpa) | (2.98 kpa) | PILOT ADJUSTMENT | ||

| 5) | Outlet Pressure Tap | ||||

| Low Setting Man. | 6.4" WC | 6.4" WC | |||

|

|

|

|

| 4) Thermocouple Connection - option | |

| Pressure | (1.59 kpa) | (1.59 kpa) | Periodically check the pilot flames. Correct | 6) | Inlet Pressure Tap |

| Max. Manifold | 10" WC | 10" WC | flame pattern has three strong blue flames: | 7) | Pilot Outlet |

| Pressure | (2.49 kpa) | (2.49 kpa) | 1 flowing around the thermopile, 1 around | 8) | Main Gas Outlet |

| Orifice Size | #51 DMS | #51 DMS | the thermocouple and 1 flowing across the | 9) | Alternative TC Connection Point |

| burner (it does not have to be touching the |

|

| |||

| Minimum Input | 25,000 Btu/h | 25,000 |

|

| |

| burner). |

|

| |||

|

| (7.33 kW) | Btu/h |

|

|

|

|

|

| (7.33 kW) | Note: If you have an incorrect flame pattern, |

|

|

| Maxiumm Input | 31,500 Btu/h | 31,500 | contact your Regency® dealer for |

|

|

| further instructions. |

|

| |||

|

| (9.23 kW) | Btu/h |

|

| |

|

|

| (9.23 kW) | Incorrect flame pattern will have small, |

|

|

|

|

|

|

|

| |

|

|

|

| probably yellow flames, not coming into |

|

|

| HIGH ELEVATION | proper contact with the rear burner or |

|

| ||

| thermopile or thermocouple. |

|

| |||

This unit is approved in Canada for altitude 0 | GAS PIPE PRESSURE |

| |

to 4500 ft. (CAN1 | TESTING |

|

GAS LINE

INSTALLATION

Since some municipalities have additional local codes it is always best to consult with your local authorities and the CAN/CGA B149 installation code.

The appliance must be isolated from the gas supply piping system by closing its individual manual

26 | Regency® |