SECTION 7: AIR SUPPLY

SECTION 7: AIR SUPPLY

7.1 Room Sealed Installation

When installed as a room sealed heater the air for combustion is drawn in from outside the building. It is important to ensure that there is adequate ventilation to provide air for the distribution fan/s.

7.2 Open Flued Installation

Ensure adequate air supply at all times for both combustion and heating requirements in accordance with local and national codes. The air supply to the heater must be fitted with a low resistance terminal to prevent the ingress of debris. See Page 12, Figure 7.

7.2.1 Heaters Installed Within the Heated Space

Where the volume of the heated space is greater than 4.7 m3 per kilowatt of total rated heat input and the air change rate is at least 0.5/h, additional high and low level ventilation will not be required.

For a building having an air change rate less than 0.5/h, ventilation will be necessary in accordance with local and national codes. Ventilation direct to outside must be provided as follows:

•Heaters above 70 kW heat input = 350 cm2 + 2.5 cm2 per kW of rated heat input above 70 kW

7.3 Building Ventilation

Where ventilation is required air must be taken from an outside point where it is not likely to be contaminated or obstructed.

Where natural ventilation is used, suitable ventilation with outside air at low level must be provided in accordance with Section 7.2.1 and local and national codes.

Where mechanical ventilation is used, extract rate must be 5% - 10% less than the inlet rate. The mechanical ventilation must be interlocked with the burner on the heater.

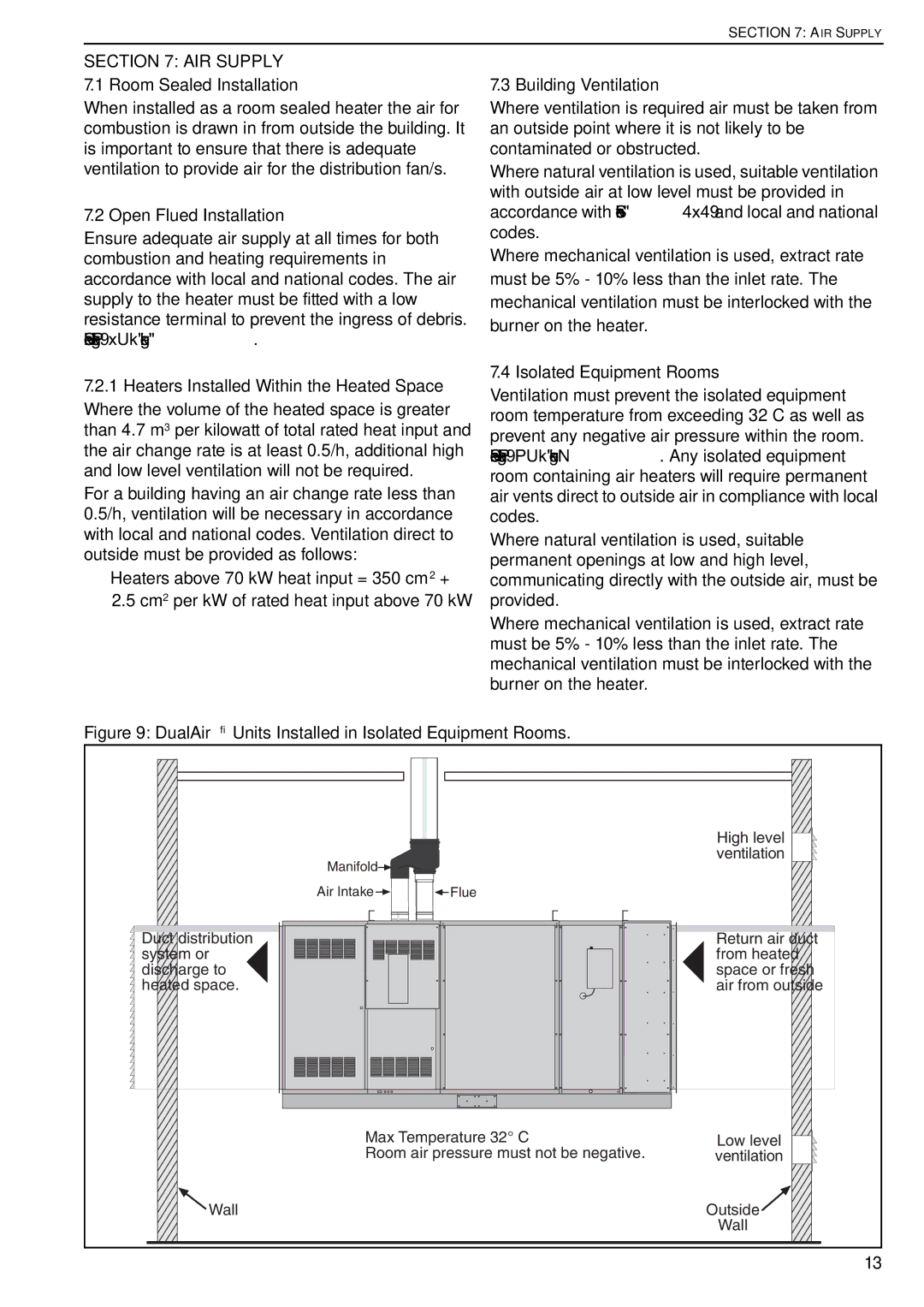

7.4 Isolated Equipment Rooms

Ventilation must prevent the isolated equipment room temperature from exceeding 32°C as well as prevent any negative air pressure within the room. See Page 13, Figure 9. Any isolated equipment room containing air heaters will require permanent air vents direct to outside air in compliance with local codes.

Where natural ventilation is used, suitable permanent openings at low and high level, communicating directly with the outside air, must be provided.

Where mechanical ventilation is used, extract rate must be 5% - 10% less than the inlet rate. The mechanical ventilation must be interlocked with the burner on the heater.

Figure 9: DualAir® Units Installed in Isolated Equipment Rooms.

High level ![]()

![]() ventilation

ventilation ![]() Manifold

Manifold![]()

![]()

![]()

Air Intake | Flue |

Duct distribution | Return air duct |

system or | from heated |

discharge to | space or fresh |

heated space. | air from outside |

Max Temperature 32° C

Room air pressure must not be negative.

![]() Wall

Wall

Low level ventilation

Outside ![]()

Wall

13