SECTION 9: GAS PIPING

SECTION 9: GAS PIPING

![]() WARNING

WARNING

Fire Hazard

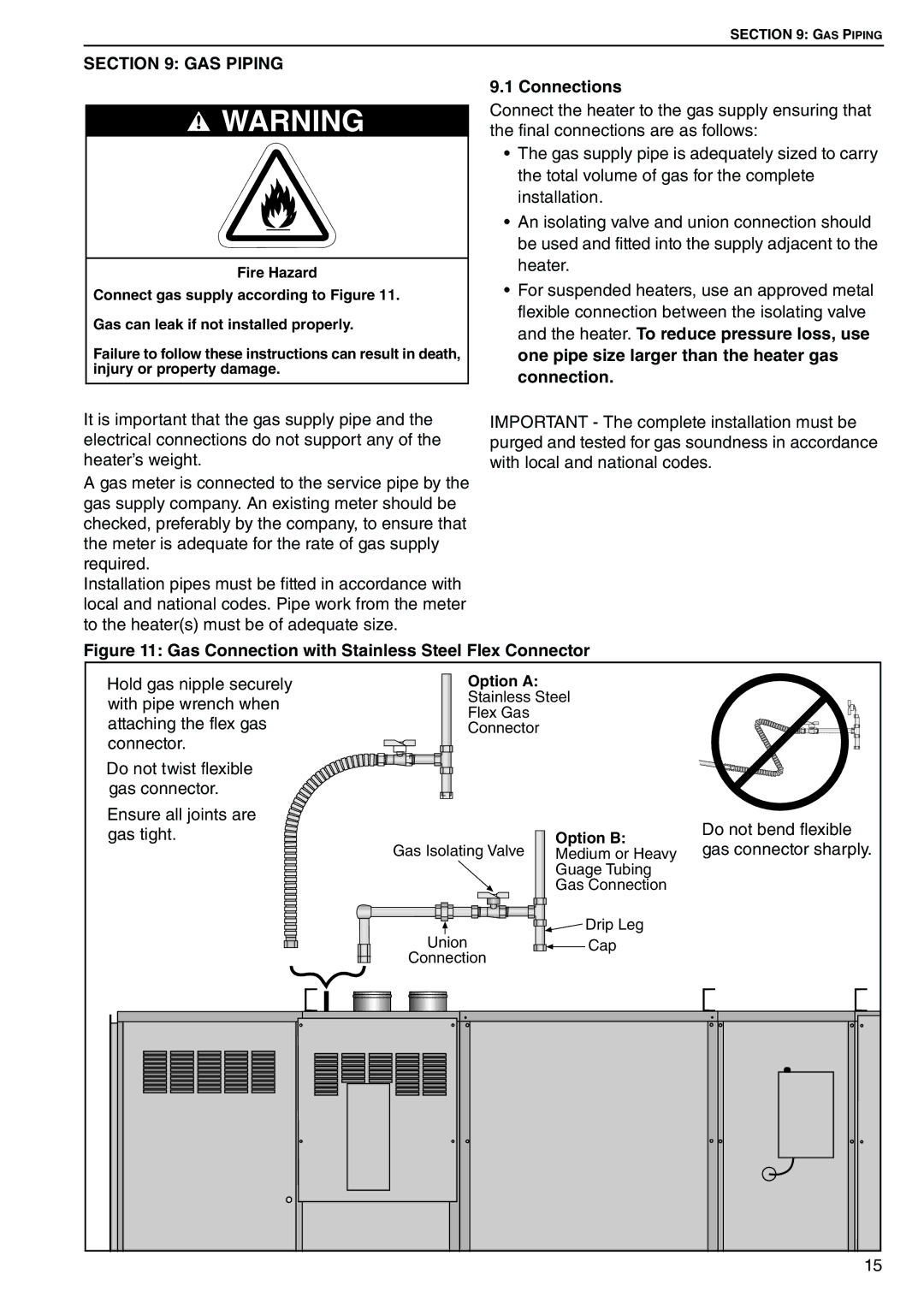

Connect gas supply according to Figure 11.

Gas can leak if not installed properly.

Failure to follow these instructions can result in death, injury or property damage.

It is important that the gas supply pipe and the electrical connections do not support any of the heater’s weight.

A gas meter is connected to the service pipe by the gas supply company. An existing meter should be checked, preferably by the company, to ensure that the meter is adequate for the rate of gas supply required.

Installation pipes must be fitted in accordance with local and national codes. Pipe work from the meter to the heater(s) must be of adequate size.

9.1 Connections

Connect the heater to the gas supply ensuring that the final connections are as follows:

•The gas supply pipe is adequately sized to carry the total volume of gas for the complete installation.

•An isolating valve and union connection should be used and fitted into the supply adjacent to the heater.

•For suspended heaters, use an approved metal flexible connection between the isolating valve and the heater. To reduce pressure loss, use one pipe size larger than the heater gas connection.

IMPORTANT - The complete installation must be purged and tested for gas soundness in accordance with local and national codes.

Figure 11: Gas Connection with Stainless Steel Flex Connector

Hold gas nipple securely with pipe wrench when attaching the flex gas connector.

Do not twist flexible gas connector.

Option A:

Stainless Steel

Flex Gas

Connector

Ensure all joints are gas tight.

Option B:

Gas Isolating Valve Medium or Heavy Guage Tubing Gas Connection

Union | Drip Leg |

Cap | |

Connection |

|

Do not bend flexible gas connector sharply.

15 |