SECTION 3: CRITICAL CONSIDERATIONS

SECTION 3: CRITICAL CONSIDERATIONS 3.1 Basic Information

The CTUD heater that forms the heating section of the DualAir® unit has an automatic ignition burner and may be operated as fully modulating or ON/OFF operation.

The standard unit has the air flow from left to right when viewed from the controls side.

A special order version with the opposite air flow is available where the combustion air intake and flue will be at the front of the unit.

3.2Location and Suspension All models:

• Must be installed indoors.

• Must be installed in a level position.

•May be mounted on the floor or on a shelf of

•May be suspended from above (See Page 9, Figure 3), on the floor, or from wall brackets of sufficient strength to support the DualAir® unit as listed in the Dimension Data Table on Page 6, Section 4.2. Drop rods must be a minimum of 12 mm diameter mild steel. Six suspension points

are located on top of the DualAir® unit.

•Must be installed in a manner which allows the hinged door to be fully opened to provide access to all serviceable components.

3.3 Minimum Required Installation Clearances

Clearances around the DualAir® unit and flue must be as indicated on Page 4, Figure 2, Page 10, Figure 4 through Page 12, Figure 8 to ensure access for servicing, and correct operation.

3.4 Clearances to Combustibles

Clearances must be as indicated on Page 4, Figure 2. If no clearances to combustibles are indicated, then installation clearances apply.

3.5 Ventilation

It is important to ensure that there is adequate air circulation around the DualAir® unit to supply air for combustion, ventilation and distribution in accordance with local and national codes.

3.6 Gas Supply

It is important that the gas supply pipe is sized correctly to provide the inlet pressure as stated on the heater data plate. The gas supply pipe and electrical connections must not support any of the heater's weight.

3.7 Electrical Supply

A permanent 400v 3ø 50Hz electrical supply is required at the main electrical terminals. The heater also requires suitable energy controls in accordance with Section 10.

3.8 Flue

Choose a location to allow for the proper alignment of the flue. Each DualAir® unit must be fitted with an individual and correctly sized sealed flue system (See Page 10, Section 6).

No other appliance may be connected to the flue. For

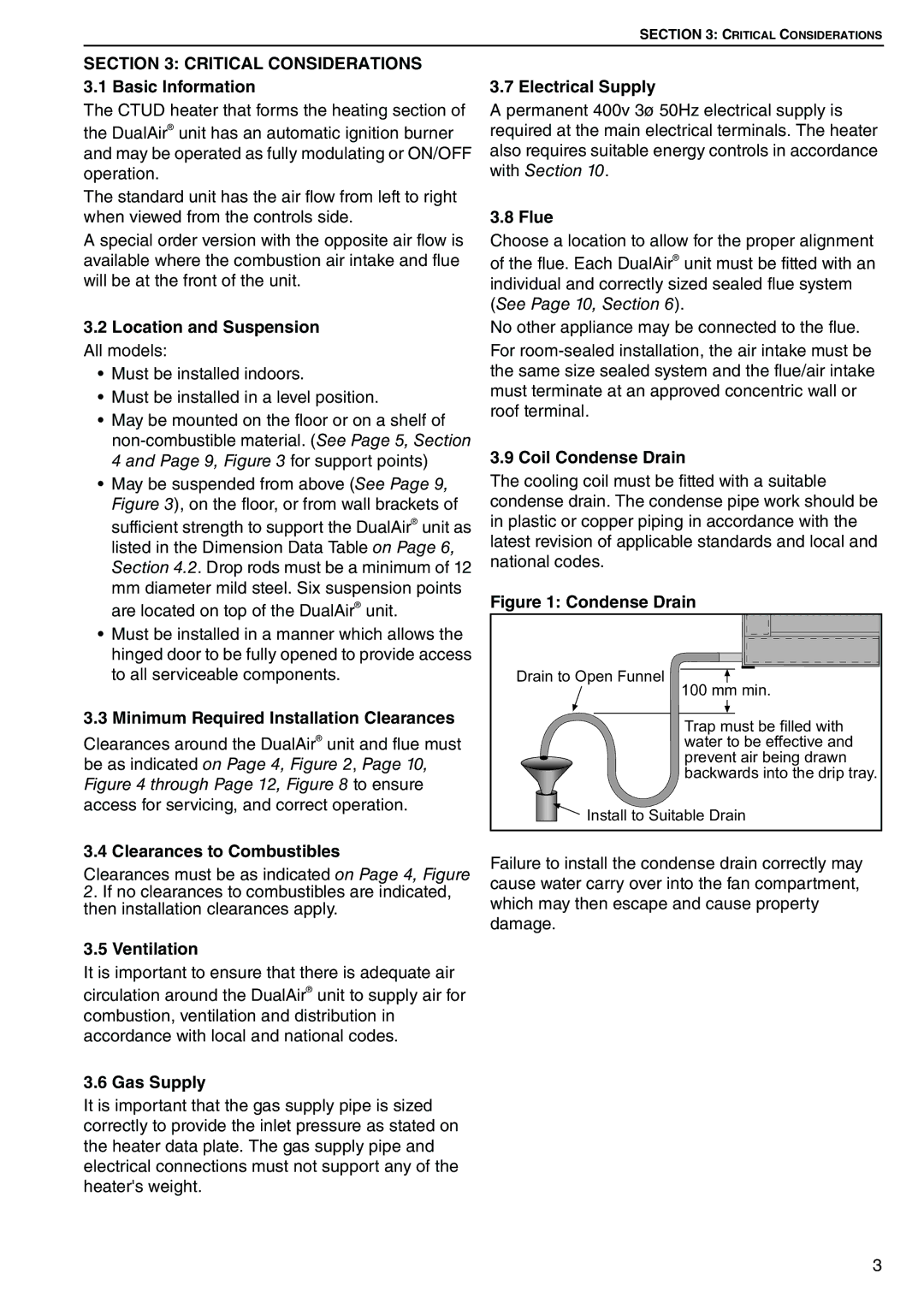

3.9 Coil Condense Drain

The cooling coil must be fitted with a suitable condense drain. The condense pipe work should be in plastic or copper piping in accordance with the latest revision of applicable standards and local and national codes.

Figure 1: Condense Drain

Drain to Open Funnel ![]()

![]() 100 mm min.

100 mm min.

Trap must be filled with water to be effective and prevent air being drawn backwards into the drip tray.

![]()

![]()

![]()

![]() Install to Suitable Drain

Install to Suitable Drain

Failure to install the condense drain correctly may cause water carry over into the fan compartment, which may then escape and cause property damage.

3