DUALAIR® HEATING AND COOLING UNITS INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 8: OPTIONAL HEATER CONFIGURATIONS 8.1 Distribution Duct

DualAir® units are designed to be connected to | The duct must be designed as described on Page | |

distribution and air inlet ducting. | 14, Section 8.1 and Figure 10 to ensure that there is | |

It is recommended that flexible duct connectors and/ | a homogenous air flow across the whole heat | |

or attenuators are used to reduce duct born noises. | exchanger. Failure to provide a properly distributed | |

air flow will reduce the life of the heat exchanger. | ||

It is recommended that the inlet ducting is arranged | ||

| ||

with both fresh air and recirculating air dampers to | Contact | |

take advantage of the "free cooling" stage provided. |

Distribution ducting must be insulated to prevent | Department for recommendations regarding | ||||||

duct resistance and design. Tel: +44 (0) 121 506 | |||||||

heat gain during cooling mode. | |||||||

7700 |

|

|

|

| |||

The air flow must be in the direction as stated for the |

|

|

|

| |||

|

|

|

|

|

| ||

version being installed with the heater at the |

|

|

|

|

|

| |

discharge end. |

|

|

|

|

|

| |

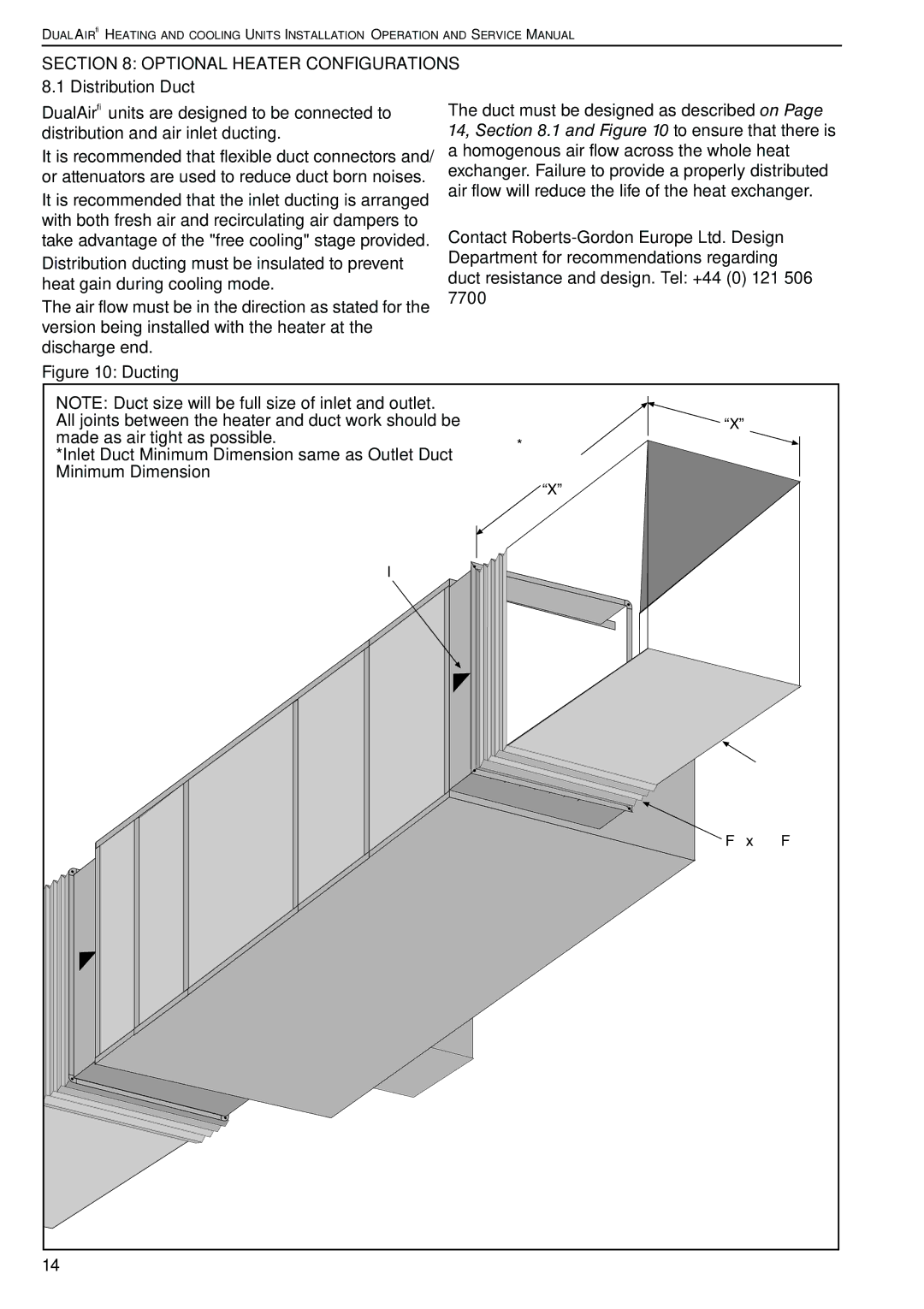

Figure 10: Ducting |

|

|

|

|

|

| |

NOTE: Duct size will be full size of inlet and outlet. |

|

|

| Dimension | |||

|

|

| |||||

All joints between the heater and duct work should be |

| “X” | |||||

made as air tight as possible. |

|

|

|

|

|

| |

|

| *Minimum- |

|

| |||

*Inlet Duct Minimum Dimension same as Outlet Duct |

|

| |||||

Twice |

|

| |||||

Minimum Dimension |

|

| Dimension |

|

| ||

|

|

| |||||

|

|

| “X” | ||||

Airflow Indicator |

|

|

|

|

|

| |

|

|

|

|

|

| ||

|

|

|

|

|

| ||

|

|

|

|

|

| ||

|

|

|

|

|

| ||

![]() Ducting

Ducting

![]() Flexible Flange

Flexible Flange

14