SECTION 15: TROUBLESHOOTING

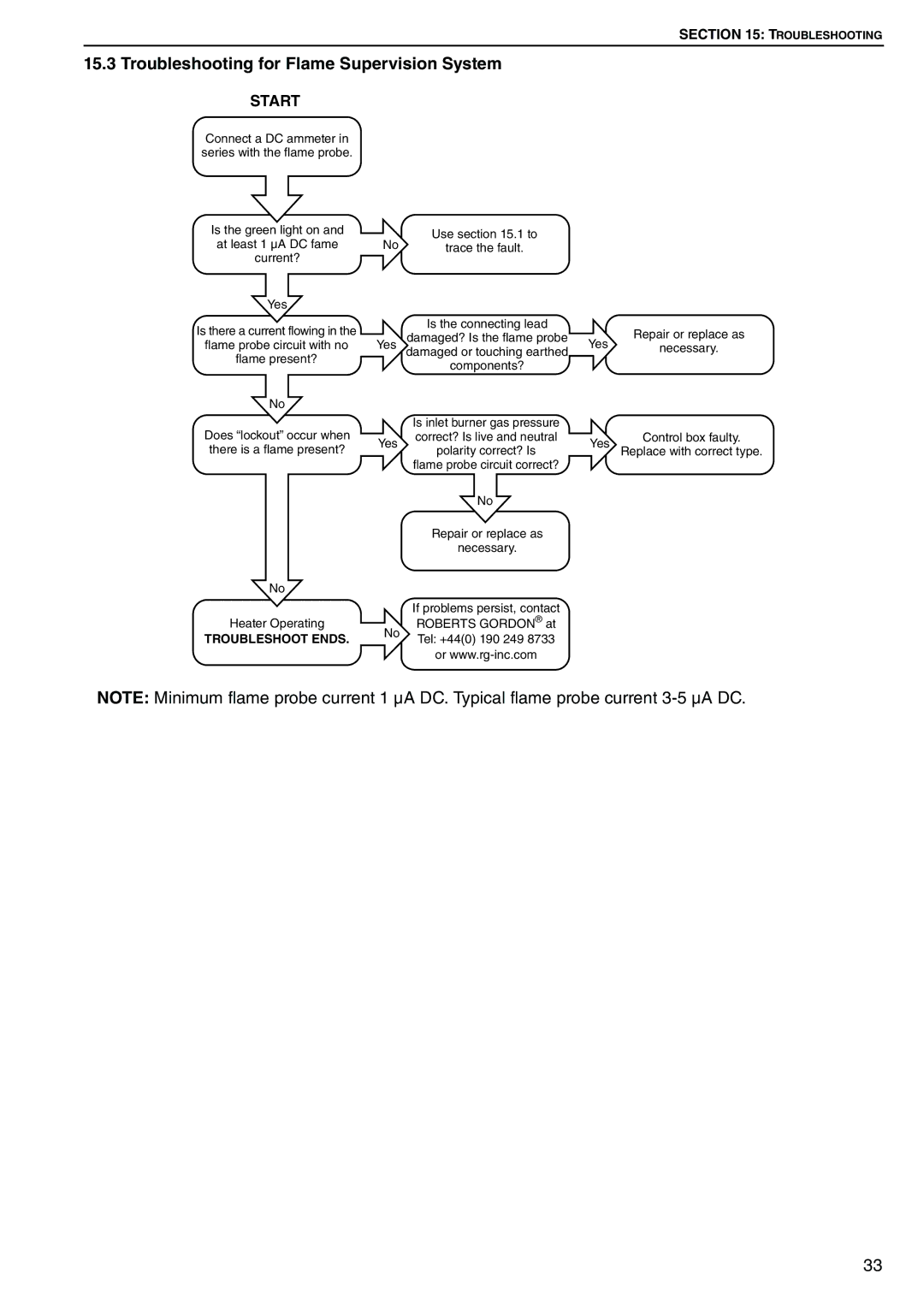

15.3 Troubleshooting for Flame Supervision System

START

Connect a DC ammeter in series with the flame probe.

Is the green light on and at least 1 µA DC fame current?

Yes

Is there a current flowing in the

flame probe circuit with no

flame present?

No

Does “lockout” occur when there is a flame present?

No

Heater Operating

TROUBLESHOOT ENDS.

No | Use section 15.1 to |

|

|

trace the fault. |

|

| |

| Is the connecting lead |

| Repair or replace as |

Yes | damaged? Is the flame probe | Yes | |

damaged or touching earthed | necessary. | ||

| components? |

|

|

| Is inlet burner gas pressure |

|

|

Yes | correct? Is live and neutral | Yes | Control box faulty. |

polarity correct? Is | Replace with correct type. | ||

| flame probe circuit correct? |

|

|

| No |

|

|

| Repair or replace as |

|

|

| necessary. |

|

|

If problems persist, contact

No | ROBERTS GORDON® at | |

Tel: +44(0) 190 249 8733 | ||

| ||

| or |

NOTE: Minimum flame probe current 1 μA DC. Typical flame probe current

33