SCN60

Service

Water System

The auger is driven at about 11 RPM by the gear reducer. The gear reducer is a sealed component and does not require lubrication, as it contains a charge of grease. The auger motor drives a set of gears that all together reduce the motor speed to the 11 RPM output speed and correspondingly increasing the torque. The output shaft of the gear reducer is hollow to accept the square end of the auger.

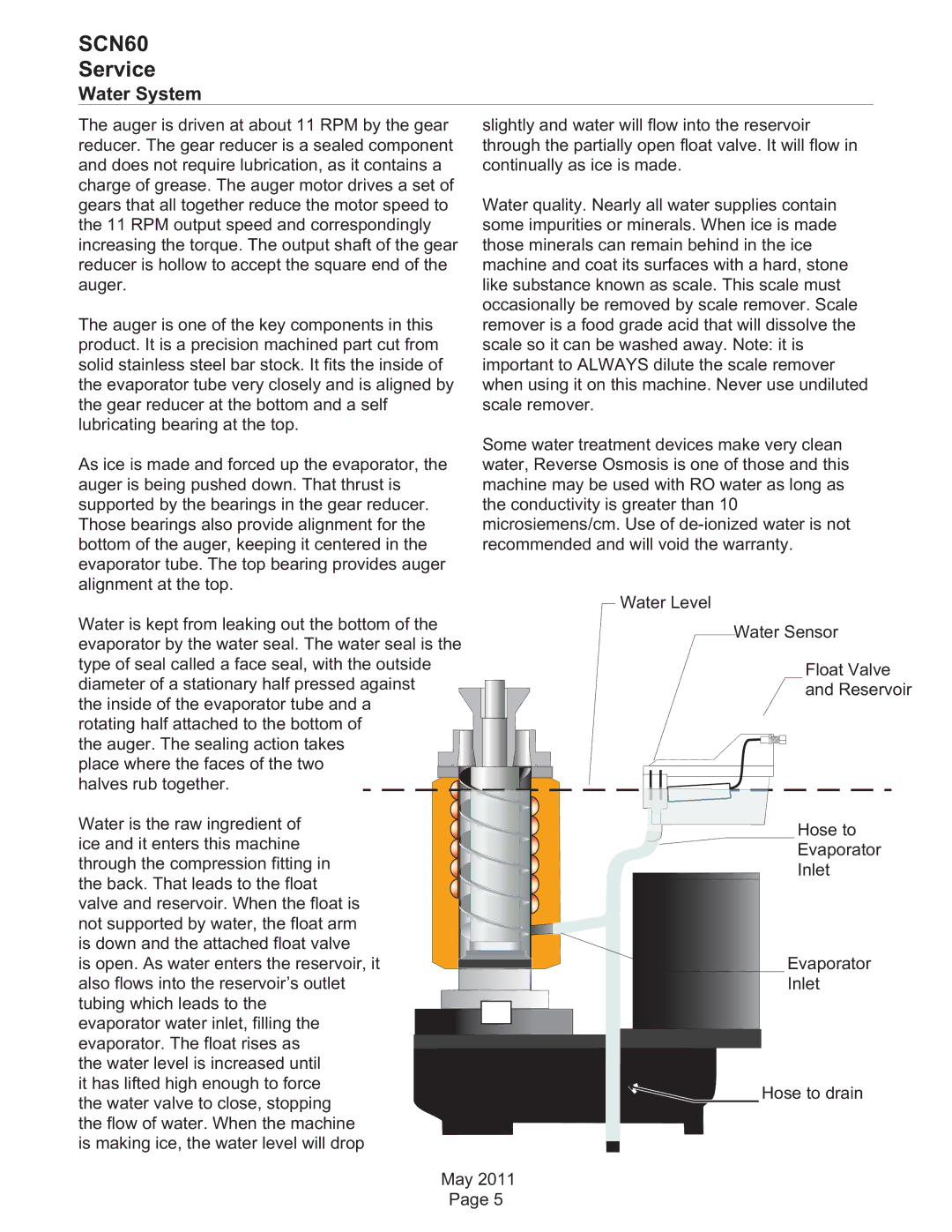

The auger is one of the key components in this product. It is a precision machined part cut from solid stainless steel bar stock. It fits the inside of the evaporator tube very closely and is aligned by the gear reducer at the bottom and a self lubricating bearing at the top.

As ice is made and forced up the evaporator, the auger is being pushed down. That thrust is supported by the bearings in the gear reducer. Those bearings also provide alignment for the bottom of the auger, keeping it centered in the evaporator tube. The top bearing provides auger alignment at the top.

slightly and water will flow into the reservoir through the partially open float valve. It will flow in continually as ice is made.

Water quality. Nearly all water supplies contain some impurities or minerals. When ice is made those minerals can remain behind in the ice machine and coat its surfaces with a hard, stone like substance known as scale. This scale must occasionally be removed by scale remover. Scale remover is a food grade acid that will dissolve the scale so it can be washed away. Note: it is important to ALWAYS dilute the scale remover when using it on this machine. Never use undiluted scale remover.

Some water treatment devices make very clean water, Reverse Osmosis is one of those and this machine may be used with RO water as long as the conductivity is greater than 10 microsiemens/cm. Use of

| Water Level | |

Water is kept from leaking out the bottom of the | Water Sensor | |

evaporator by the water seal. The water seal is the | ||

| ||

type of seal called a face seal, with the outside | Float Valve | |

diameter of a stationary half pressed against | ||

and Reservoir | ||

the inside of the evaporator tube and a | ||

| ||

rotating half attached to the bottom of |

| |

the auger. The sealing action takes |

| |

place where the faces of the two |

| |

halves rub together. |

| |

Water is the raw ingredient of | Hose to | |

ice and it enters this machine | ||

Evaporator | ||

through the compression fitting in | ||

Inlet | ||

the back. That leads to the float | ||

| ||

valve and reservoir. When the float is |

| |

not supported by water, the float arm |

| |

is down and the attached float valve |

| |

is open. As water enters the reservoir, it | Evaporator | |

also flows into the reservoir’s outlet | Inlet | |

tubing which leads to the |

| |

evaporator water inlet, filling the |

| |

evaporator. The float rises as |

| |

the water level is increased until |

| |

it has lifted high enough to force | Hose to drain | |

the water valve to close, stopping | ||

| ||

the flow of water. When the machine |

| |

is making ice, the water level will drop |

| |

May 2011 |

| |

Page 5 |

|