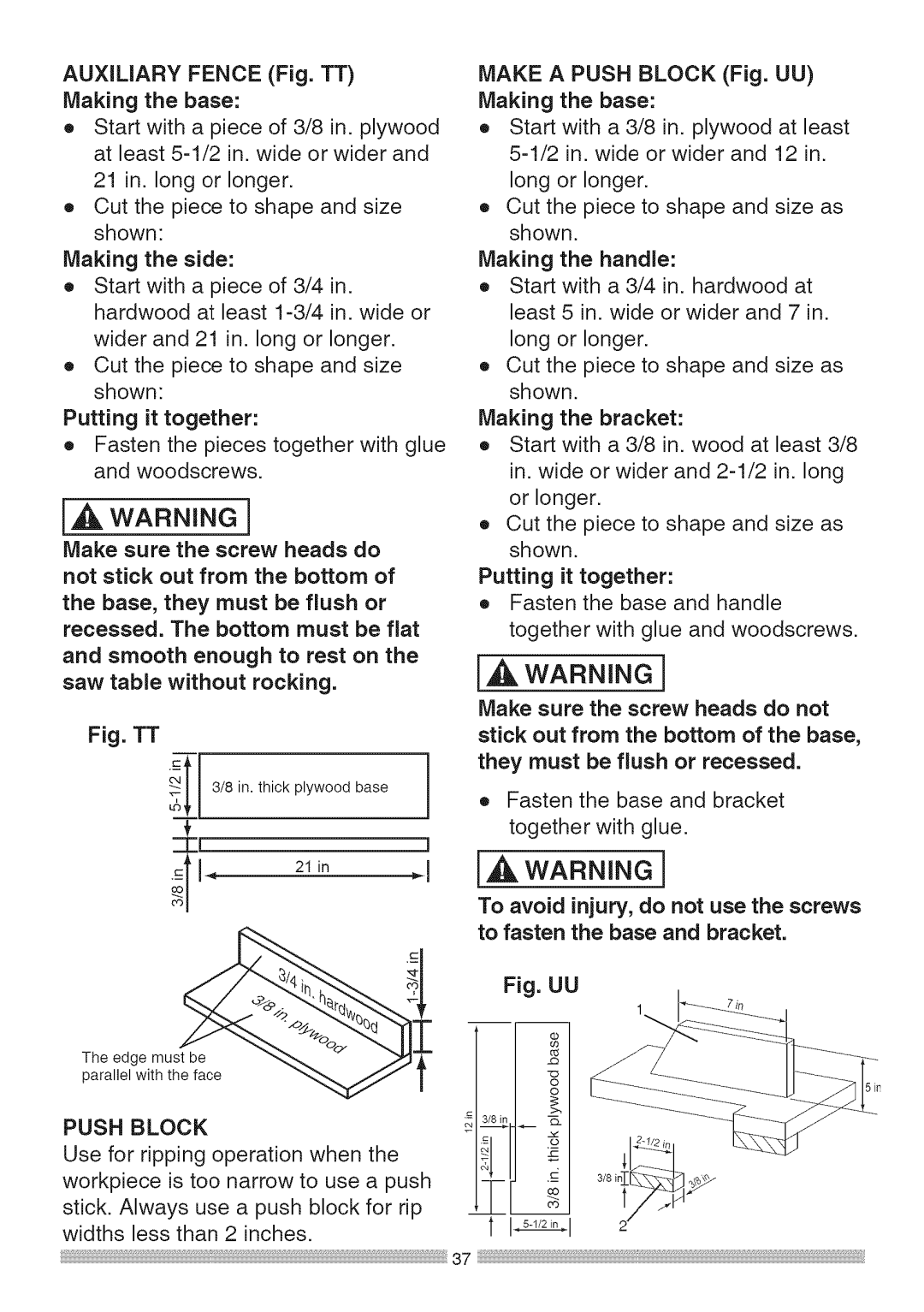

AUXILIARY FENCE (Fig. TT)

Making the base:

oStart with a piece of 3/8 in. plywood at least

21 in. long or longer.

oCut the piece to shape and size shown:

Making the side:

oStart with a piece of 3/4 in. hardwood at least

wider and 21 in. long or longer.

oCut the piece to shape and size shown:

Putting it together:

oFasten the pieces together with glue and woodscrews.

i,,_ WARNING]

Make sure the screw heads do not stick out from the bottom of the base, they must be flush or recessed. The bottom must be flat and smooth enough to rest on the saw table without rocking.

Fig. TT

_I ! 3/8 in. thick plywood base

!

The edge must be parallel with the face

PUSH BLOCK

Use for ripping operation when the workpiece is too narrow to use a push stick. Always use a push block for rip widths less than 2 inches.

MAKE A PUSH BLOCK (Fig. UU) Making the base:

oStart with a 3/8 in. plywood at least

long or longer.

oCut the piece to shape and size as shown.

Making the handle:

oStart with a 3/4 in. hardwood at least 5 in. wide or wider and 7 in.

long or longer.

oCut the piece to shape and size as shown.

Making the bracket:

o Start with a 3/8 in. wood at least 3/8 in. wide or wider and

oCut the piece to shape and size as shown.

Putting it together:

oFasten the base and handle together with glue and woodscrews.

l,_ WARNING]

Make sure the screw heads do not stick out from the bottom of the base, they must be flush or recessed.

oFasten the base and bracket together with glue.

l,_ WARNING j

To avoid injury, do not use the screws to fasten the base and bracket.

Fig. UU

m_

37