6 Configuring and Programming the CP as a PROFINET IO Device

Transfer the process inputs (DB10) to the I addresses with PNIO_SEND

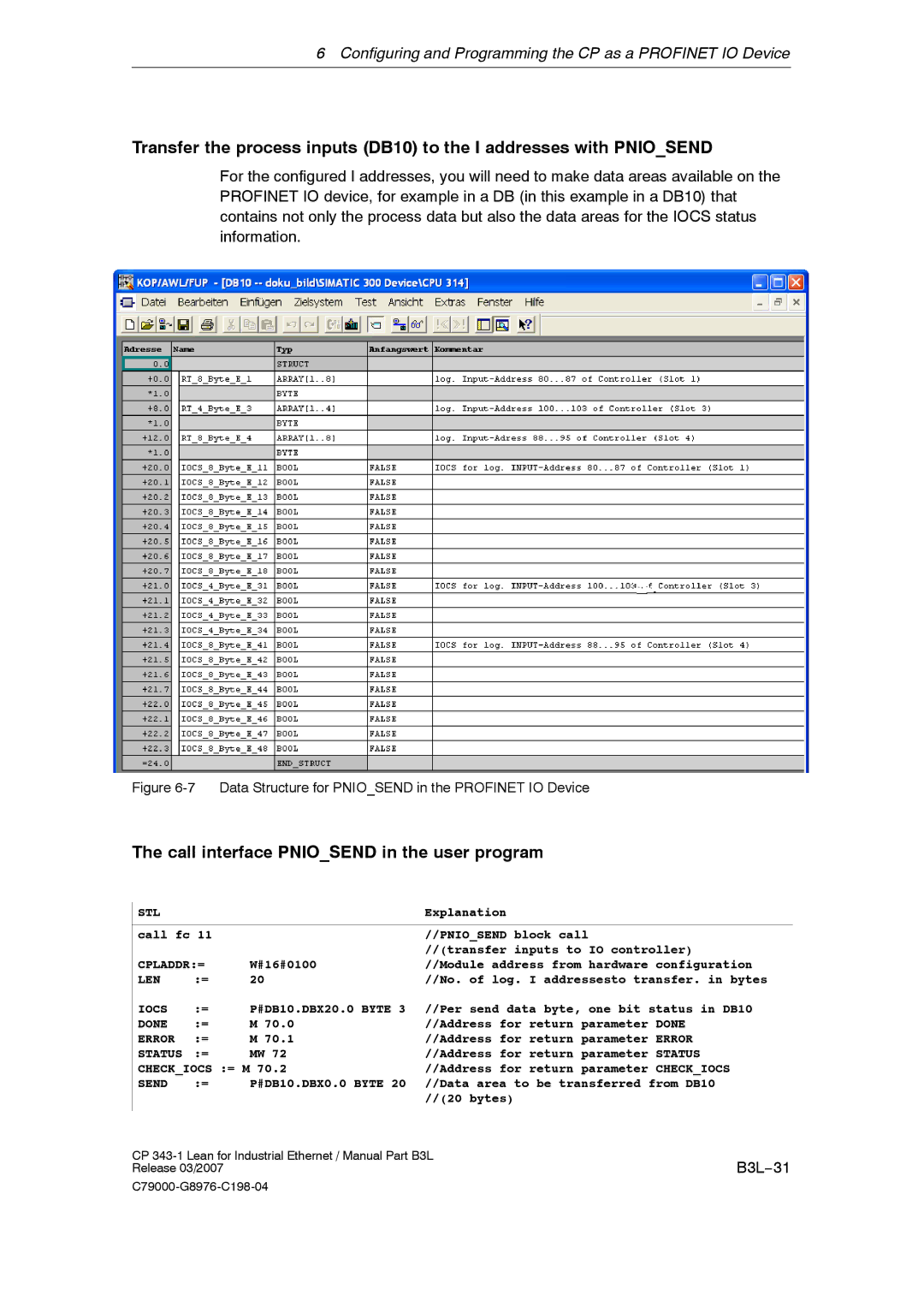

For the configured I addresses, you will need to make data areas available on the PROFINET IO device, for example in a DB (in this example in a DB10) that contains not only the process data but also the data areas for the IOCS status information.

Figure 6-7 Data Structure for PNIO_SEND in the PROFINET IO Device

The call interface PNIO_SEND in the user program

STL |

|

| Explanation |

|

|

|

|

| |

call fc 11 |

| //PNIO_SEND block call |

| |

|

|

| //(transfer inputs to IO controller) | |

CPLADDR:= | W#16#0100 | //Module address from hardware | configuration | |

LEN | := | 20 | //No. of log. I addressesto transfer. in bytes | |

IOCS | := | P#DB10.DBX20.0 BYTE 3 | //Per send data byte, one bit status in DB10 | |

DONE | := | M 70.0 | //Address for return parameter | DONE |

ERROR | := | M 70.1 | //Address for return parameter | ERROR |

STATUS | := | MW 72 | //Address for return parameter | STATUS |

CHECK_IOCS := M 70.2 | //Address for return parameter | CHECK_IOCS | ||

SEND | := | P#DB10.DBX0.0 BYTE 20 | //Data area to be transferred from DB10 | |

|

|

| //(20 bytes) |

|

|

| |||

CP | B3L−31 | |||

Release 03/2007 |

|

| ||