3 Operating the SAMMS-MV Device

ture of the rotor and provides a signal to trip the motor

You can select motor cold stall time from 5 to 100 seconds in increments of 1 second. The selected time will adjust the rotor loop elements so that the maximum temperature limit in the rotor is reached under locked rotor conditions for the time selected. If cold stall time is not known, the rotor model will assume a cold stall time based on the type of motor used. The user is allowed to select an open drip proof (ODP) motor or a totally enclosed

3.21 Repetitive Starts

The motor model allows repetitive starts without nuisance tripping while protecting the motor against overload and stall conditions. Repetitive starts can occur as long as the following conditions are met:

1.The energy exerted by the motor during start does not exceed the energy defined by the overload class selected.

2.The motor winding temperature does not exceed the maxi- mum temperature allowed.

3.The rotor temperature does not exceed the maximum temperature allowed.

4.The

For example, a motor starting from cold condition could have 4 or more typical starts of 5 seconds without nuisance tripping and without damaging the motor insulation. Figure 3.12 shows a

3.22 Start Inhibit

When the motor temperature reaches the maximum values allowed, the

3.23 Cooling Time Constants

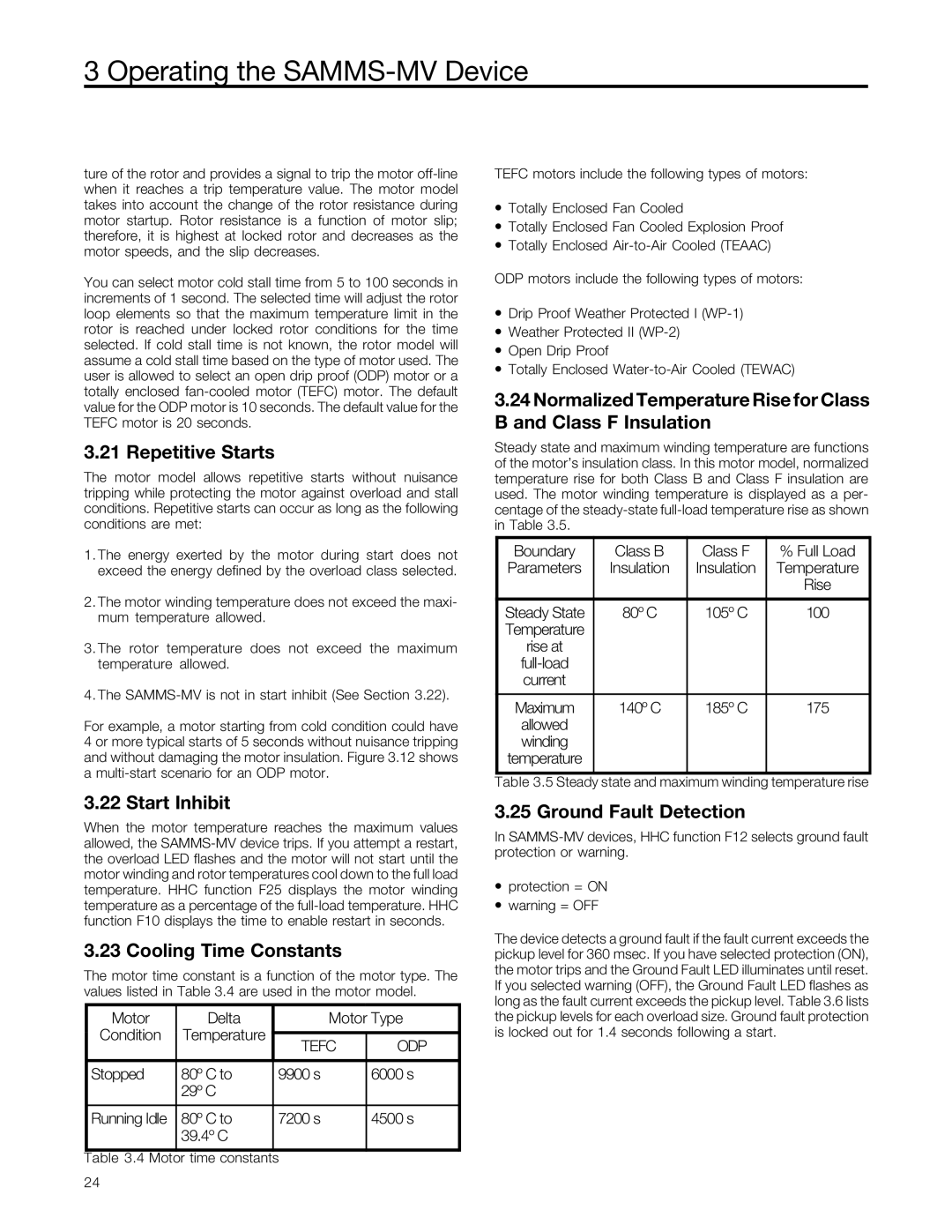

The motor time constant is a function of the motor type. The values listed in Table 3.4 are used in the motor model.

Motor | Delta | Motor Type | ||

Condition | Temperature |

|

| |

TEFC | ODP | |||

|

| |||

|

|

|

| |

Stopped | 80º C to | 9900 s | 6000 s | |

| 29º C |

|

| |

|

|

|

| |

Running Idle | 80º C to | 7200 s | 4500 s | |

| 39.4º C |

|

| |

Table 3.4 Motor time constants

TEFC motors include the following types of motors:

∙Totally Enclosed Fan Cooled

∙Totally Enclosed Fan Cooled Explosion Proof

∙Totally Enclosed

ODP motors include the following types of motors:

∙Drip Proof Weather Protected I

∙Weather Protected II

∙Open Drip Proof

∙Totally Enclosed

3.24Normalized Temperature Rise for Class B and Class F Insulation

Steady state and maximum winding temperature are functions of the motor’s insulation class. In this motor model, normalized temperature rise for both Class B and Class F insulation are used. The motor winding temperature is displayed as a per- centage of the

Boundary | Class B | Class F | % Full Load |

Parameters | Insulation | Insulation | Temperature |

|

|

| Rise |

|

|

|

|

Steady State | 80º C | 105º C | 100 |

Temperature |

|

|

|

rise at |

|

|

|

|

|

| |

current |

|

|

|

|

|

|

|

Maximum | 140º C | 185º C | 175 |

allowed |

|

|

|

winding |

|

|

|

temperature |

|

|

|

Table 3.5 Steady state and maximum winding temperature rise

3.25 Ground Fault Detection

In

∙protection = ON

∙warning = OFF

The device detects a ground fault if the fault current exceeds the pickup level for 360 msec. If you have selected protection (ON), the motor trips and the Ground Fault LED illuminates until reset. If you selected warning (OFF), the Ground Fault LED flashes as long as the fault current exceeds the pickup level. Table 3.6 lists the pickup levels for each overload size. Ground fault protection is locked out for 1.4 seconds following a start.

24