1 Introduction

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

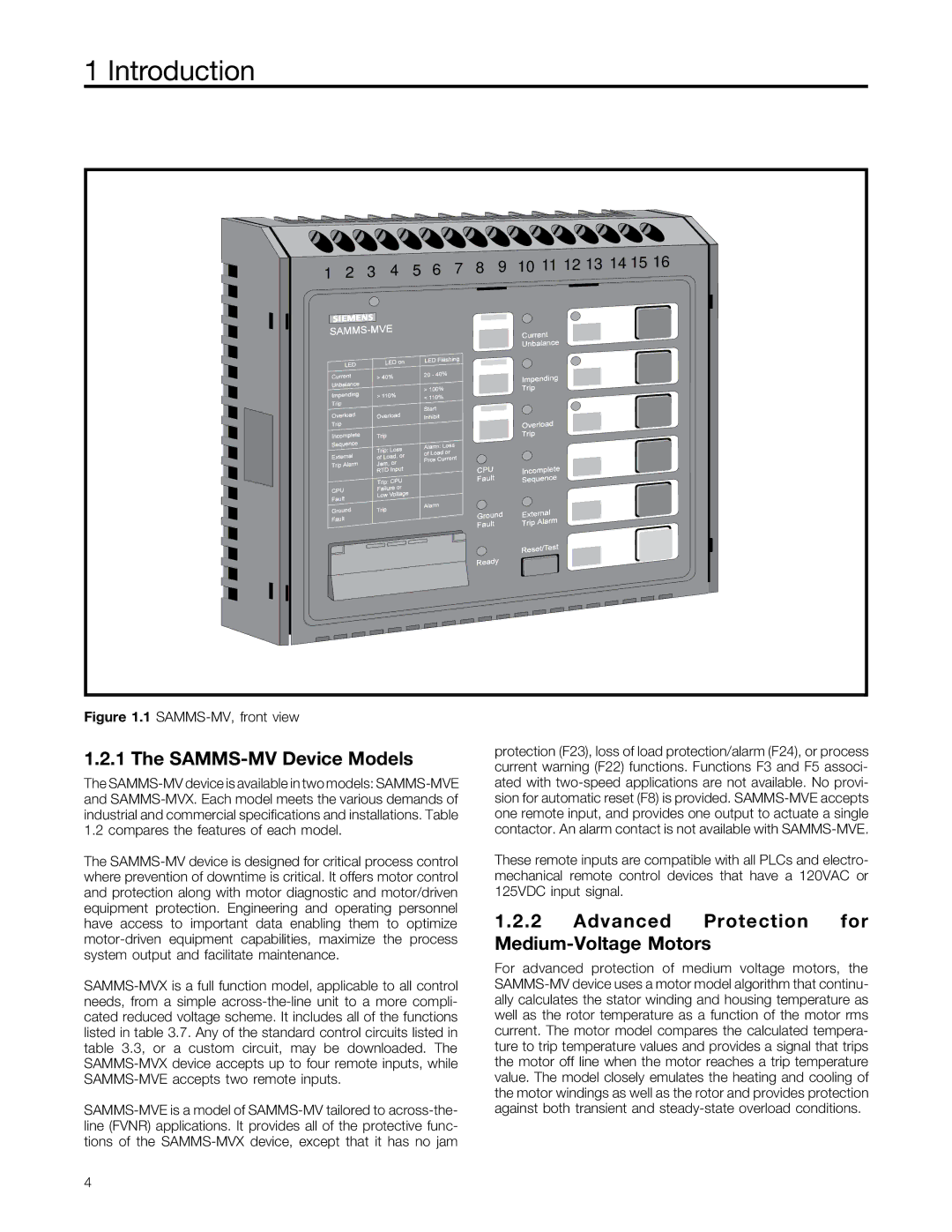

Figure 1.1 SAMMS-MV, front view

1.2.1 The SAMMS-MV Device Models

The

The

protection (F23), loss of load protection/alarm (F24), or process current warning (F22) functions. Functions F3 and F5 associ- ated with

These remote inputs are compatible with all PLCs and electro- mechanical remote control devices that have a 120VAC or 125VDC input signal.

1.2.2 Advanced Protection for Medium-Voltage Motors

For advanced protection of medium voltage motors, the

4