3700

Table of Contents

Glossary of Terms

General Safety Rules

Personal Safety

Work Area

Tool Use

Table Saw Specific Safety Rules

Basic Operation and Set Up

Tool Care

Rip Cutting

Cross Cutting

Plunge Cutting

Dragged into the blade during a kickback

Shop Safety Rules

Accessory Power Outlet

Non-Through Cutting Dado, Rabbet, Resawing

Kickback

Router Table Safety

Sander Safety

Throwing fragments

Jigsaw Safety

Double Insulated Tools

Grounded Tools

Extension Cords

Replace damaged cords immediately

Page

Utilisation des accessoires X-Shop avec

Table des matières

« Conservez CES Instructions »

Informations relatives à la sécurité

Lexique

Consignes générales de sécurité

Zone de travail

Sécurité de l’utilisateur

Utilisation de l’outil

Consignes de sécurité pour les scies de table

Protection de l’outil

Utilisation et réglages élémentaires

Prenez Soin DE VOS Outils ET ENTRETENEZ-LES Bien

Refente

Sciage en travers

Sciage en plongée

Consignes de sécurité pour X-Shop

Coupes non débouchantes Rainures, feuillures, dédoublement

Consignes de sécurité pour une table à toupie

Coincera le matériau et risquera de causer un rebond

De causer une perte de contrôle

Consignes de sécurité Pour une scie à chantourner

Outils à double isolation

Outils mis à la terre

Cordons de rallonge

En la matière

Étiquettes d’avertissement

Pour Continuation DU FRANÇAIS, REPORTEZ-VOUS À LA

Índice

Guarde Estas Instrucciones

Glosario de términos

Normas generales de seguridad

Area de trabajo

Seguridad personal

Utilización de la herramienta

Cuidado de la herramienta

Funcionamiento y preparación básicos

Evite LAS Areas DE Gases

Mantenga LAS Herramientas CON Cuidado

Corte al hilo

Corte transversal

Corte por penetración

Corte no pasante De mortaja, rebajo o reaserrado

Sea consciente de la proximidad de la mano y los dedos a la

Instrucciones de seguridad para mesas de fresadora

Podría causar una pérdida de control

Instrucciones de seguridad Para sierras caladoras

Herramientas con aislamiento doble

Herramientas conectadas a tierra

Cordones de extensión

Conserve Estas Instrucciones

Etiquetas de advertencia

VER Continuación DEL Español EN LA Página

Unpacking Checking Contents

Pièces détachées dans le carton

Piezas sueltas contenidas en la caja de cartón

Assembly Kits

Cabinet P Arts

Small parts

Kits de montage Juegos de ensamblajes

Ensemble du coffret Ensamblaje del armario

Hardware Kit Sander Insert

Hardware Kit Jigsaw Insert

Hardware Kit Blank Insert

Guide de ponceuse Guide de toupie

Plaquette amovible pour ponceuse

Tope-guía de lijadora Tope-guía de fresadora

Juego de ensamblaje de sierra

Tools Needed For Assembly

Hardware Kit Router Insert

Outils nécessaires à l’assemblage

Herramientas necesarias para el ensamblaje

Plaquette amovible pour toupie

Juego de herrajes del accesorio

Assembly

Assembling Cabinet

AssemblageEnsamblaje

Assemblage du coffret

Ensamblaje del armario

C16 C19 C17

Assemblage du coffret suite

Ensamblaje del armario continuación

Attaching Wings

Attaching Front Rails

Montage des ailes

Montage du rail avant

Ensamblaje de las alas

Colocación del riel delantero

Attaching Digital Display

Attaching Handle To Rip Fence

T18

Colocación del mango en El tope-guía para cortar al hilo

Montage de l’écran ’affichage numérique

Attach handle to wheel using bolt as shown in figure

Attaching Handle to Elevation Wheel

Montage du guide de refente

Réglage de hauteur

Colocación del tope-guía Para cortar al hilo

Colocación del mango en el rueda de Elevacion

Attaching Blade Guard

Montage du protège-lame

Colocación del protector de la hoja

Perno hexagonal de 1/4-20 x 2 pulg

Wings and blank insert must be installed

Attaching Blank Insert

Order to use the table saw. Wings and blank

Montage de l’ébauche de plaquette amovible

Attaching Router Insert

Outil non joint / Herramienta no incluida

Montage de la plaquette Amovible pour toupie

’emploi qui accompagne la toupie

Art Description

Instrucciones que vino con la fresadora

Attaching Sander Insert

Montage de la plaquette amovible pour ponceuse

De instrucciones que vino con la lijadora

Attaching Jigsaw Insert

Montage de la plaquette amovible Pour scie à chantourner

Colocación del accesorio De inserción de sierra caladora

Getting To Know Your Shop

Outils X-Shop

Taller convertible X-Shop

Accessory Tool Inserts

Wrench Storage

RIP Fence Storage

Cord Wrap

Rangement DES Clés

Rangement DU Guide DE Refente

Rangement DU Guide DE Coupe Angulaire

Rangement DU Cordon

Miter Gauge

Router not included

Sander not included

Jigsaw not included

Plaquettes Amovibles Pour Accessoires

Guide DE Coupe Angulaire

Accesorios DE Inserción Para Herramientas

Calibre DE Ingletes

Table Saw Adjustments

Adjusting 90 and 45 Degree Positive Stops

Adjusting Positive Stop AT 90 Degrees

Adjusting Positive Stop AT 45 Degrees

Réglage des butées positives 90 et 45 degrés

Control de inclinación de la hoja

Ajuste de los topes positivos 90 y 45 grados

Para el calibre de ingletes

Adjusting Blade Parallel To Miter Gauge Slots

Changing The Blade

Remplacement de la lame

Cambio de la hoja

De changer la lame

De cambiar las hojas

Manual Pointer Adjustment

Miter Gauge Adjustment

Shop Tools Adjustments

Aligning Rip Fence

Alignement du guide de refente

Réglage manuel de l’aiguille

Alineación del tope-guía Para cortar al hilo

Ajuste manual del indicador

Table Saw Power Switch

Using the Miter Gauge with T Bar

Using The Miter Gauge

Basic Table Saw Operation

Utilización básica De la sierra de mesa

Work Helpers

Push Stick and Push Block

Auxiliary Fence

Accessoires de sciage

Ayudantes de trabajo

Palo de empujar y bloque de empujar

Guide auxiliaire

Using the Rip Fence

Utilisation du guide de refente

Utilización del tope-guía Para cortar al hilo

Pour votre propre sécurité

Error Messages

Operating the Digital Display

Ripping

Mensajes DE Error

Refente

Corte al hilo

Messages D’ERREUR

Bevel Ripping

Crosscutting

Refente biseautée

Coupe transversale

Corte al hilo en bisel

Corte transversal

Repetitive Cutting

Miter Cutting

Bevel Crosscutting

Compound Miter Cutting

Coupes à répétition

Coupe angulaire

Coupe transversale biseautée

Coupe angulaire combinée

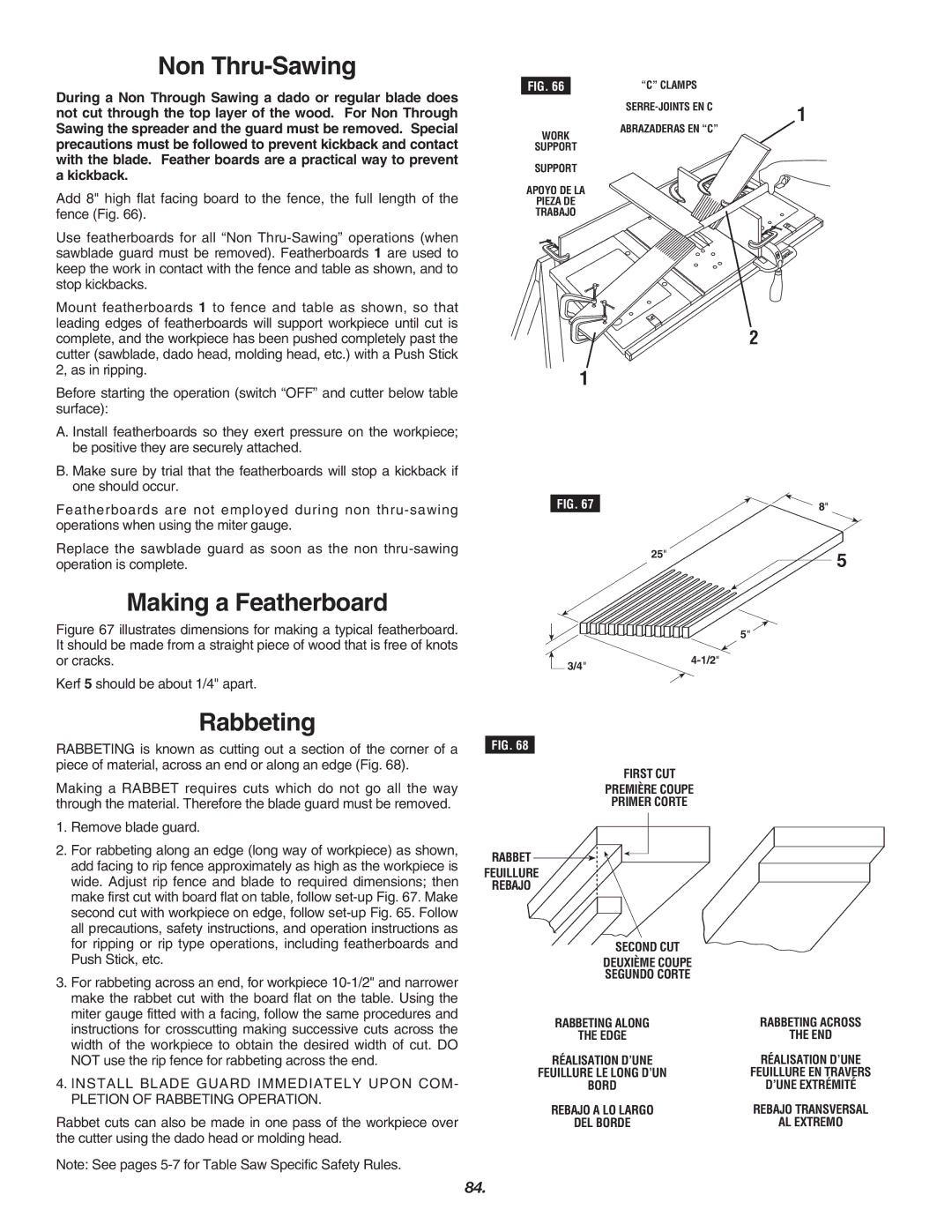

Non Thru-Sawing

Making a Featherboard

Rabbeting

Sciage non débouchant

Feuillure

Aserrado no pasante

Elaboración de una tabla De canto biselado

Dado Cutting

Resawing

Special Cutting Techniques

Rainure

Corte de mortajas

Coupe à dédoublement

Techniques de coupe spéciales

Using X-Shop Accessories With Inserts

Never leave the power tool unattended while it is

Off position

Running or before it comes to a complete stop

Avant qu’il ne soit complètement à l’arrêt

De apagado

To Adjust the Fence Opening for Router BIT Clearance FIG

To Adjust the Depth of CUT FIG

To Adjust the Router BIT Height

Installing the Router BIT Positioning the Guard

Utilisation de la toupie X-Shop

Utilización de la fresadora X-Shop

Routing Using the Feather Board

Using the Feather Board on Table TOP

Using the Feather Board On the Fence Figure

Fence Location and Workpiece Feed

SUR LE Dessus DE LA Table

SUR LE Guide Figure

Sobre EL Tablero DE LA Mesa

Sobre EL TOPE-GUÍA Figura

Routing Using the Fence

Jointing Full Edge Cutting

Installez une mèche droite dans la toupie

Junteo Corte DE Bordes Completos

Instale una broca recta en la fresadora

Edge Cutting with NON-PILOTED Router Bits

Edge Cutting with Piloted Router Bits

Installez la mèche désirée dans la toupie

NON Pilotées

SIN Punta Piloto

Toupie Pilotées

GROOVING, FLUTING, and Veining

Création DE RAINURES, D’ENTAILLES ET DE Veinures

RANURADO, Estriado Y Acanalado

Shop Sander Operation

Pinching or entrapment of fingers

Utilisation de la ponceuse X-Shop

Utilización de la lijadora X-Shop

Shop Jigsaw Operation

Utilización de la sierra caladora X-Shop

Maintenance

Maintaining Your Shop

Lubrication

Mantenimiento de la sierra De mesa X-Shop

Mantenimiento

Lubrification

Lubricación

Recommended Accessories

Use only recommended accessories. Follow

Instructions that accompany accessories

Use of improper accessories may cause hazards

Accesorios recomendados

Trouble Shooting

Guide de diagnostic

Localización y reparación De averías

Averia LA Sierra no Arranca

110

RemarquesNotas

Limited Warranty of Skil Benchtop Tools