HELP16

Adhesive bond | |

Grease | |

Grease |

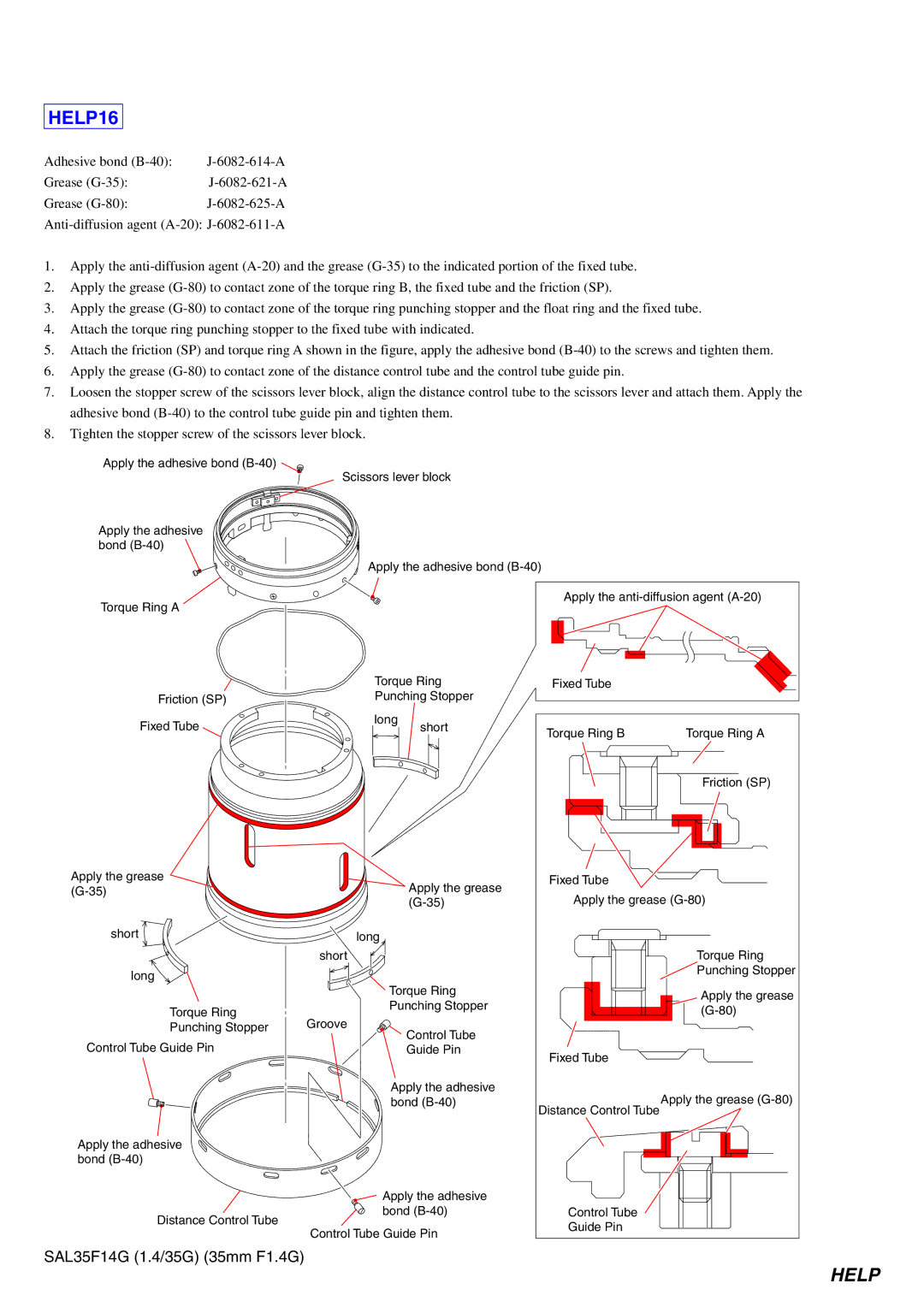

1.Apply the

2.Apply the grease

3.Apply the grease

4.Attach the torque ring punching stopper to the fixed tube with indicated.

5.Attach the friction (SP) and torque ring A shown in the figure, apply the adhesive bond

6.Apply the grease

7.Loosen the stopper screw of the scissors lever block, align the distance control tube to the scissors lever and attach them. Apply the adhesive bond

8.Tighten the stopper screw of the scissors lever block.

Apply the adhesive bond

Apply the adhesive bond

Torque Ring A

Scissors lever block

Apply the adhesive bond

Apply the

Friction (SP)

Fixed Tube

Apply the grease

short

long

Torque Ring

Punching Stopper

Control Tube Guide Pin

Apply the adhesive bond

Distance Control Tube

Torque Ring

Punching Stopper

long

short

Apply the grease

long

short

Torque Ring

Punching Stopper

Groove

Control Tube

Guide Pin

Apply the adhesive bond

Apply the adhesive bond

Control Tube Guide Pin

Fixed Tube

Torque Ring B | Torque Ring A |

Friction (SP)

Fixed Tube

Apply the grease

Torque Ring

![]() Punching Stopper

Punching Stopper

Apply the grease

Fixed Tube

Apply the grease

Distance Control Tube

Control Tube

Guide Pin

SAL35F14G (1.4/35G) (35mm F1.4G)