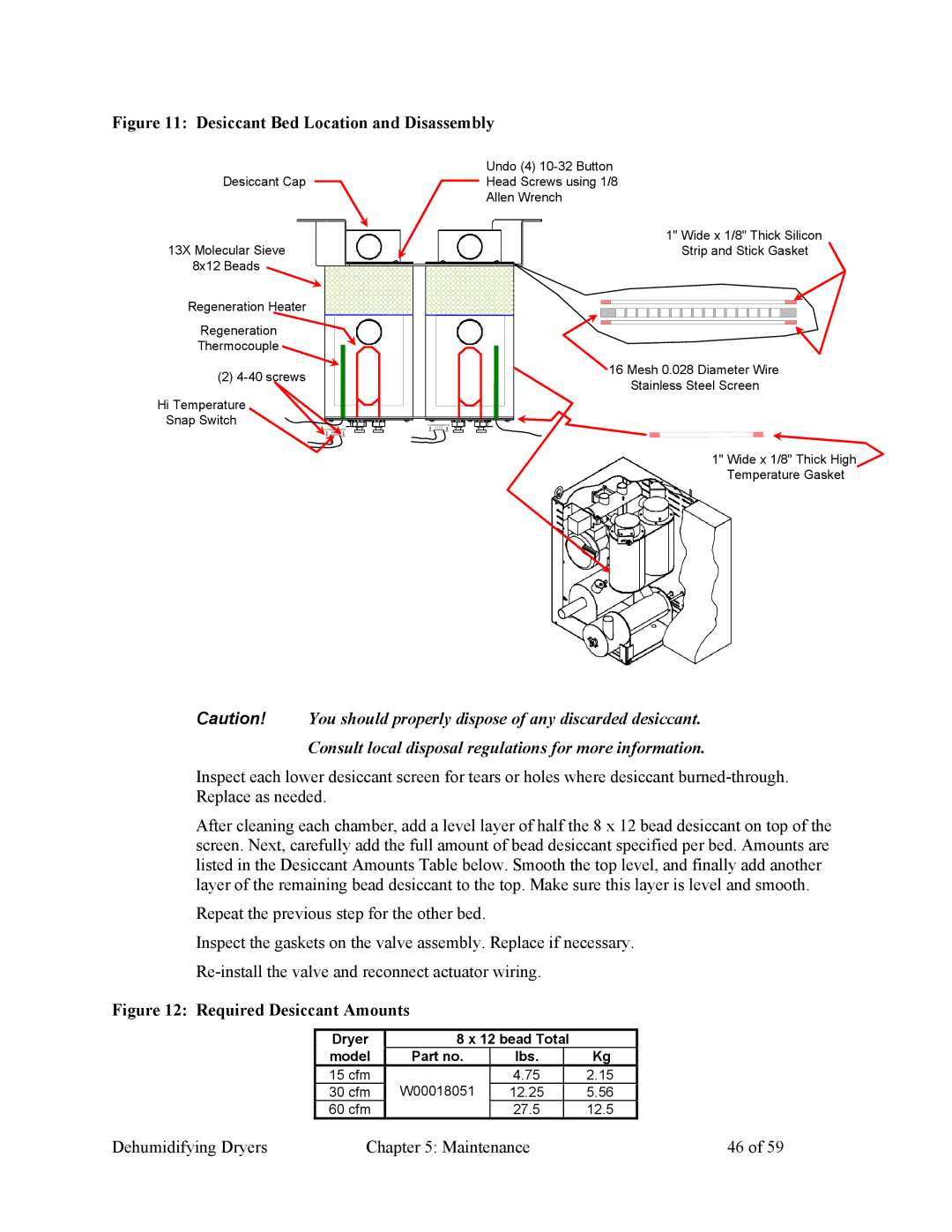

Figure 11: Desiccant Bed Location and Disassembly

Desiccant Cap

13X Molecular Sieve

8x12 Beads

Regeneration Heater

Regeneration

Thermocouple

(2)

Hi Temperature

Snap Switch

Undo (4)

Head Screws using 1/8

Allen Wrench

1" Wide x 1/8" Thick Silicon

Strip and Stick Gasket

16 Mesh 0.028 Diameter Wire

Stainless Steel Screen

1" Wide x 1/8" Thick High

Temperature Gasket

Caution! You should properly dispose of any discarded desiccant.

Consult local disposal regulations for more information.

Inspect each lower desiccant screen for tears or holes where desiccant

After cleaning each chamber, add a level layer of half the 8 x 12 bead desiccant on top of the screen. Next, carefully add the full amount of bead desiccant specified per bed. Amounts are listed in the Desiccant Amounts Table below. Smooth the top level, and finally add another layer of the remaining bead desiccant to the top. Make sure this layer is level and smooth.

Repeat the previous step for the other bed.

Inspect the gaskets on the valve assembly. Replace if necessary.

Figure 12: Required Desiccant Amounts

| Dryer | 8 x 12 bead Total |

|

| ||

| model | Part no. | lbs. |

| Kg |

|

| 15 cfm | W00018051 | 4.75 |

| 2.15 |

|

| 30 cfm | 12.25 |

| 5.56 |

| |

| 60 cfm |

| 27.5 |

| 12.5 |

|

Dehumidifying Dryers | Chapter 5: Maintenance |

| 46 of 59 | |||