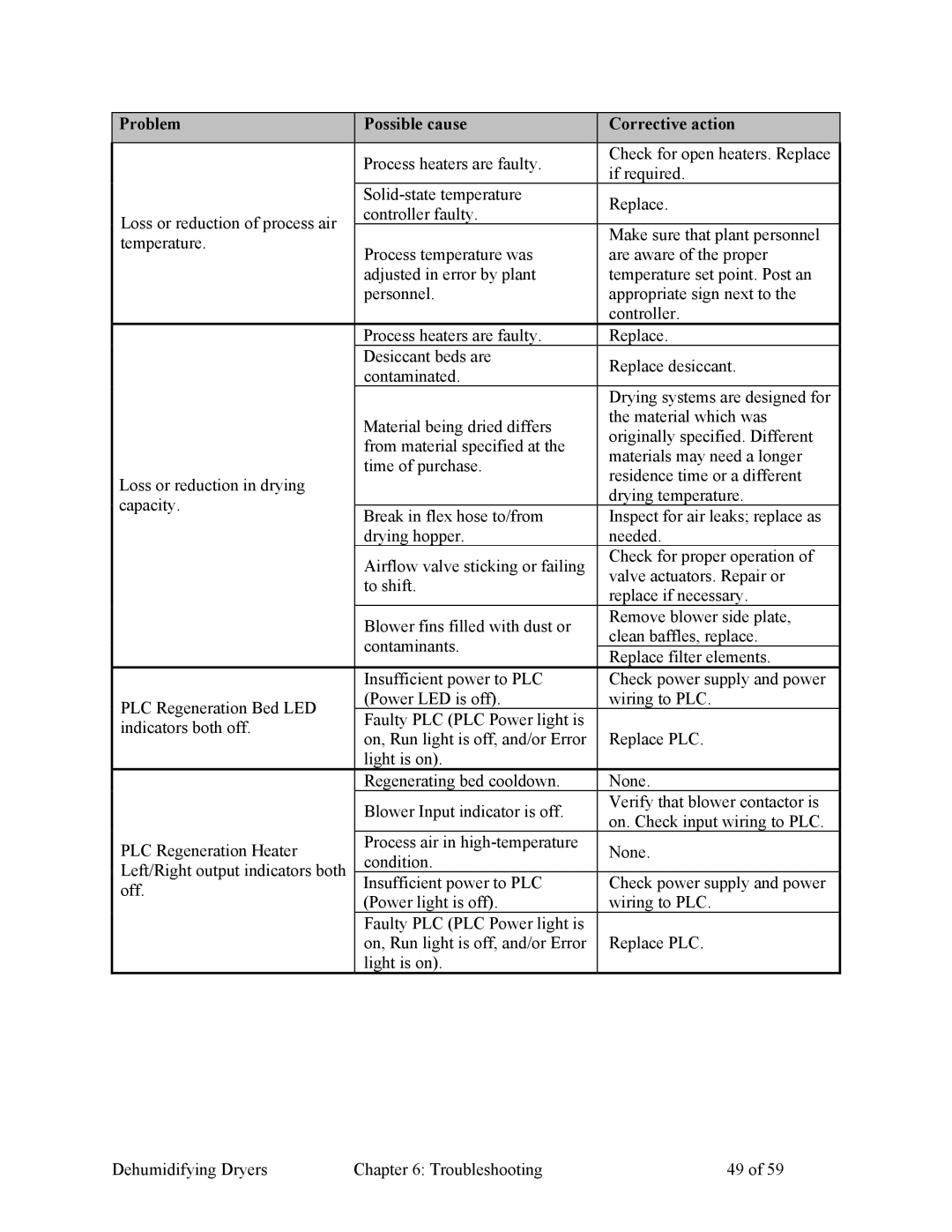

| Problem |

| Possible cause |

| Corrective action |

|

|

|

|

|

|

|

|

| Process heaters are faulty. |

| Check for open heaters. Replace |

|

|

|

| if required. | |

|

|

|

|

| |

|

|

|

| Replace. | |

| Loss or reduction of process air |

| controller faulty. |

| |

|

|

|

| ||

|

|

|

| Make sure that plant personnel | |

| temperature. |

|

|

| |

|

| Process temperature was |

| are aware of the proper | |

|

|

|

| ||

|

|

| adjusted in error by plant |

| temperature set point. Post an |

|

|

| personnel. |

| appropriate sign next to the |

|

|

|

|

| controller. |

|

|

| Process heaters are faulty. |

| Replace. |

|

|

| Desiccant beds are |

| Replace desiccant. |

|

|

| contaminated. |

| |

|

|

|

|

| |

|

|

|

|

| Drying systems are designed for |

|

|

| Material being dried differs |

| the material which was |

|

|

|

| originally specified. Different | |

|

|

| from material specified at the |

| |

|

|

|

| materials may need a longer | |

|

|

| time of purchase. |

| |

Loss or reduction in drying |

|

| residence time or a different | ||

|

|

| |||

|

|

| drying temperature. | ||

capacity. |

|

|

| ||

| Break in flex hose to/from |

| Inspect for air leaks; replace as | ||

|

|

|

| ||

|

|

| drying hopper. |

| needed. |

|

|

| Airflow valve sticking or failing |

| Check for proper operation of |

|

|

|

| valve actuators. Repair or | |

|

|

| to shift. |

| |

|

|

|

| replace if necessary. | |

|

|

|

|

| |

|

|

| Blower fins filled with dust or |

| Remove blower side plate, |

|

|

|

| clean baffles, replace. | |

|

|

| contaminants. |

| |

|

|

|

| Replace filter elements. | |

|

|

|

|

| |

|

|

| Insufficient power to PLC |

| Check power supply and power |

| PLC Regeneration Bed LED |

| (Power LED is off). |

| wiring to PLC. |

|

| Faulty PLC (PLC Power light is |

|

| |

| indicators both off. |

|

| Replace PLC. | |

|

| on, Run light is off, and/or Error |

| ||

|

|

|

| ||

|

|

| light is on). |

|

|

|

|

| Regenerating bed cooldown. |

| None. |

|

|

| Blower Input indicator is off. |

| Verify that blower contactor is |

|

|

|

| on. Check input wiring to PLC. | |

|

|

|

|

| |

| PLC Regeneration Heater |

| Process air in |

| None. |

|

| condition. |

| ||

| Left/Right output indicators both |

|

|

| |

|

| Insufficient power to PLC |

| Check power supply and power | |

| off. |

| (Power light is off). |

| wiring to PLC. |

|

|

|

| ||

|

|

| Faulty PLC (PLC Power light is |

|

|

|

|

| on, Run light is off, and/or Error |

| Replace PLC. |

|

|

| light is on). |

|

|

Dehumidifying Dryers | Chapter 6: Troubleshooting | 49 of 59 |