ASSEMBLY

HOSE AND CABLE ROUTING

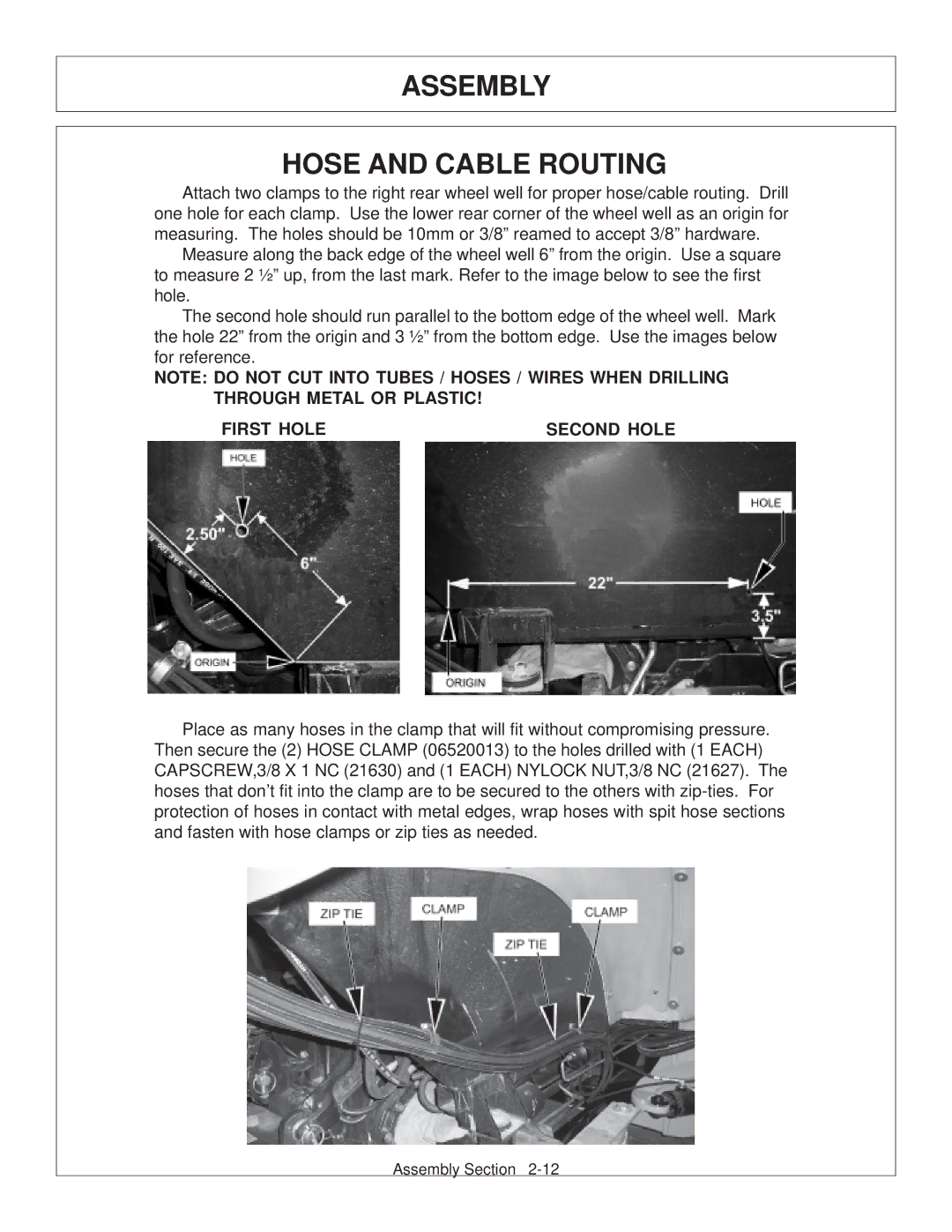

Attach two clamps to the right rear wheel well for proper hose/cable routing. Drill one hole for each clamp. Use the lower rear corner of the wheel well as an origin for measuring. The holes should be 10mm or 3/8” reamed to accept 3/8” hardware.

Measure along the back edge of the wheel well 6” from the origin. Use a square to measure 2 ½” up, from the last mark. Refer to the image below to see the first hole.

The second hole should run parallel to the bottom edge of the wheel well. Mark the hole 22” from the origin and 3 ½” from the bottom edge. Use the images below for reference.

NOTE: DO NOT CUT INTO TUBES / HOSES / WIRES WHEN DRILLING THROUGH METAL OR PLASTIC!

FIRST HOLE | SECOND HOLE |

Place as many hoses in the clamp that will fit without compromising pressure. Then secure the (2) HOSE CLAMP (06520013) to the holes drilled with (1 EACH) CAPSCREW,3/8 X 1 NC (21630) and (1 EACH) NYLOCK NUT,3/8 NC (21627). The hoses that don’t fit into the clamp are to be secured to the others with

Assembly Section