MAINTENANCE

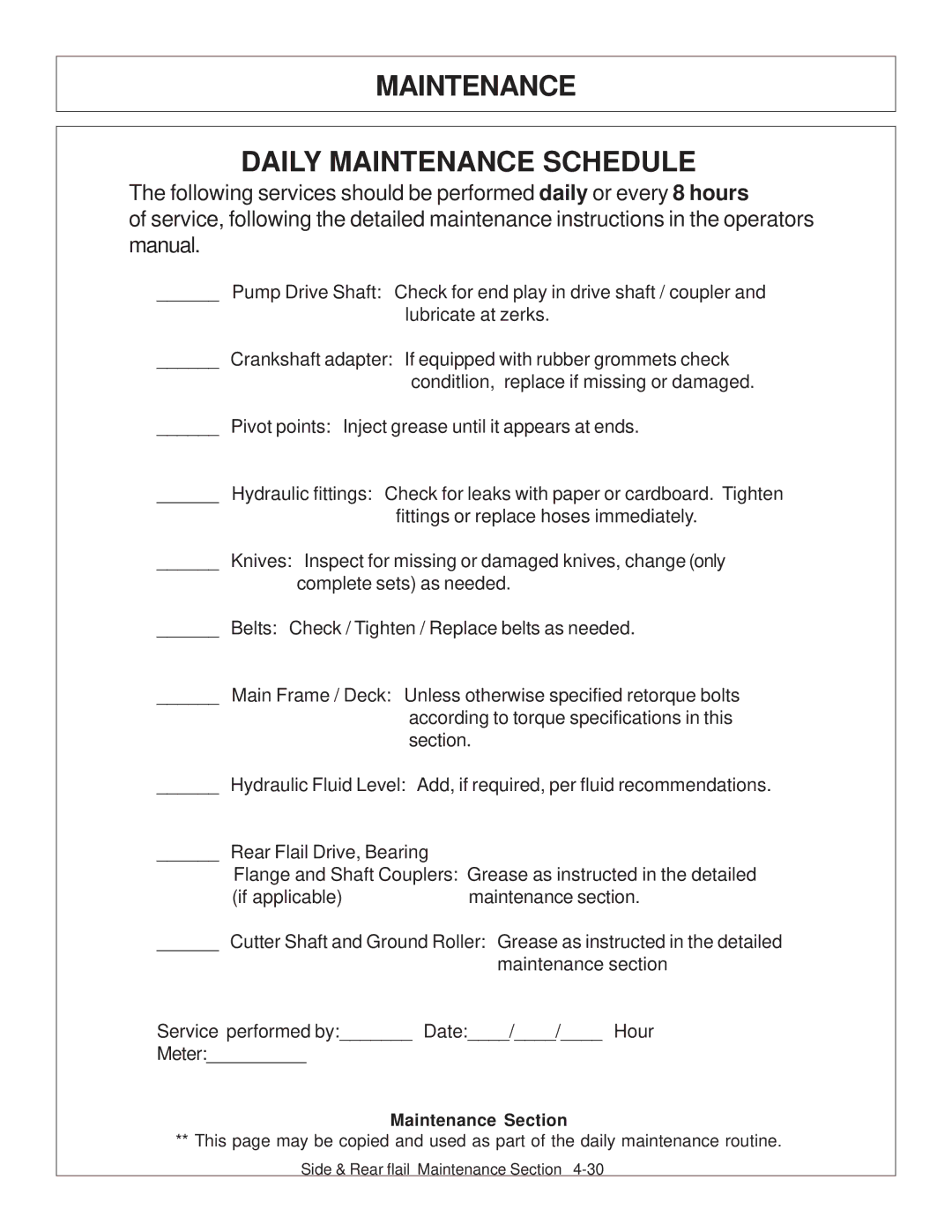

DAILY MAINTENANCE SCHEDULE

The following services should be performed daily or every 8 hours

of service, following the detailed maintenance instructions in the operators manual.

______ | Pump Drive Shaft: Check for end play in drive shaft / coupler and | |

| lubricate at zerks. | |

______ | Crankshaft adapter: If equipped with rubber grommets check | |

| conditlion, replace if missing or damaged. | |

______ | Pivot points: Inject grease until it appears at ends. | |

______ | Hydraulic fittings: Check for leaks with paper or cardboard. Tighten | |

| fittings or replace hoses immediately. | |

______ | Knives: Inspect for missing or damaged knives, change(only | |

| complete sets) as needed. | |

______ | Belts: Check / Tighten / Replace belts as needed. | |

______ | Main Frame / Deck: Unless otherwise specified retorque bolts | |

| according to torque specifications in this | |

| section. | |

______ | Hydraulic Fluid Level: Add, if required, per fluid recommendations. | |

______ | Rear Flail Drive, Bearing | |

| Flange and Shaft Couplers: Grease as instructed in the detailed | |

| (if applicable) | maintenance section. |

______ | Cutter Shaft and Ground Roller: Grease as instructed in the detailed | |

|

| maintenance section |

Service performed by:_______ | Date:____/____/____ Hour | |

Meter:__________ |

| |

Maintenance Section

** This page may be copied and used as part of the daily maintenance routine.

Side & Rear flail Maintenance Section