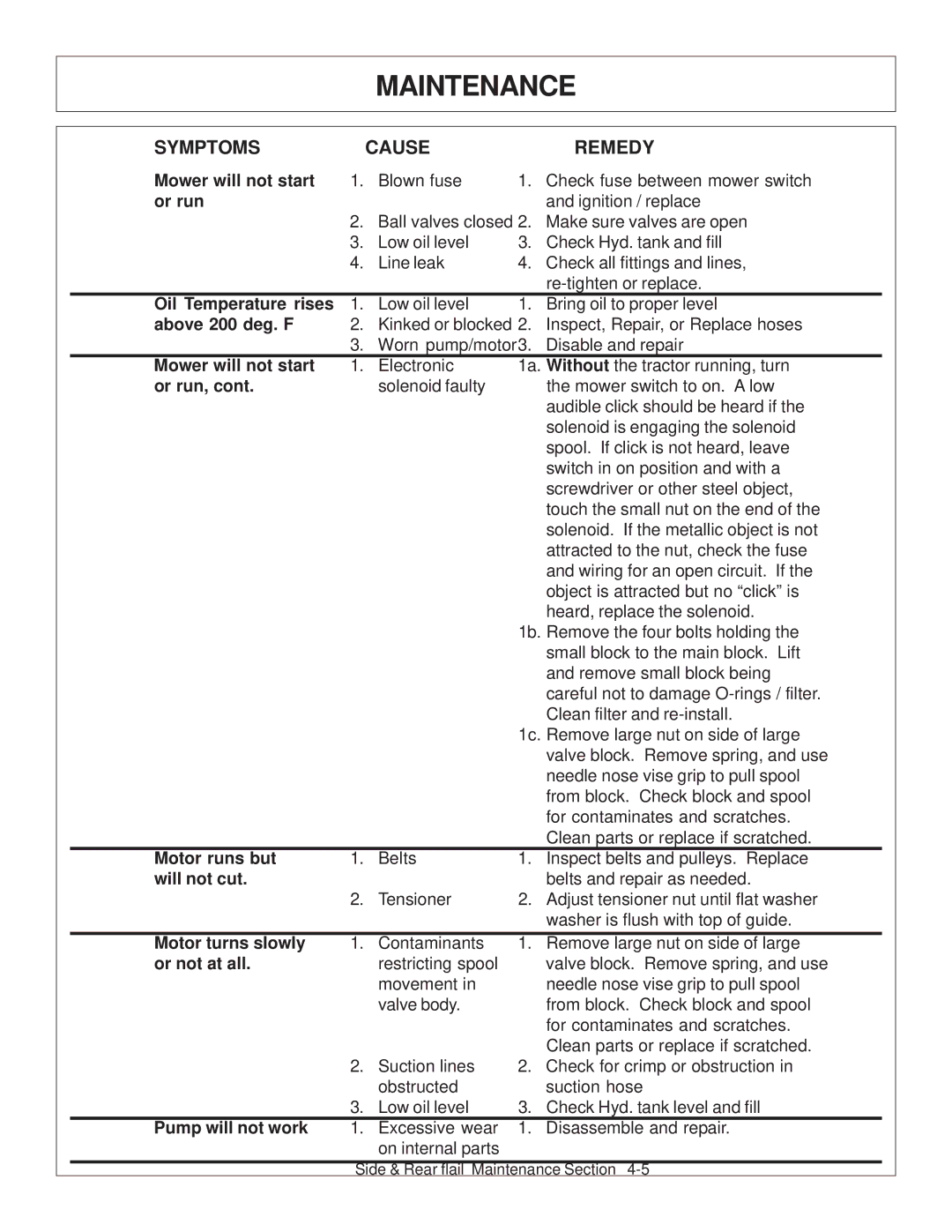

MAINTENANCE

SYMPTOMS |

| CAUSE |

| REMEDY |

Mower will not start | 1. | Blown fuse | 1. | Check fuse between mower switch |

or run |

|

|

| and ignition / replace |

| 2. | Ball valves closed 2. | Make sure valves are open | |

| 3. | Low oil level | 3. | Check Hyd. tank and fill |

| 4. | Line leak | 4. | Check all fittings and lines, |

|

|

|

| |

Oil Temperature rises | 1. | Low oil level | 1. | Bring oil to proper level |

above 200 deg. F | 2. | Kinked or blocked 2. | Inspect, Repair, or Replace hoses | |

| 3. | Worn pump/motor3. | Disable and repair | |

Mower will not start | 1. | Electronic | 1a. | Without the tractor running, turn |

or run, cont. |

| solenoid faulty |

| the mower switch to on. A low |

|

|

|

| audible click should be heard if the |

|

|

|

| solenoid is engaging the solenoid |

|

|

|

| spool. If click is not heard, leave |

|

|

|

| switch in on position and with a |

|

|

|

| screwdriver or other steel object, |

|

|

|

| touch the small nut on the end of the |

|

|

|

| solenoid. If the metallic object is not |

|

|

|

| attracted to the nut, check the fuse |

|

|

|

| and wiring for an open circuit. If the |

|

|

|

| object is attracted but no “click” is |

|

|

|

| heard, replace the solenoid. |

|

|

| 1b. | Remove the four bolts holding the |

|

|

|

| small block to the main block. Lift |

|

|

|

| and remove small block being |

|

|

|

| careful not to damage |

|

|

|

| Clean filter and |

|

|

| 1c. | Remove large nut on side of large |

|

|

|

| valve block. Remove spring, and use |

|

|

|

| needle nose vise grip to pull spool |

|

|

|

| from block. Check block and spool |

|

|

|

| for contaminates and scratches. |

|

|

|

| Clean parts or replace if scratched. |

Motor runs but | 1. | Belts | 1. | Inspect belts and pulleys. Replace |

will not cut. |

|

|

| belts and repair as needed. |

| 2. | Tensioner | 2. | Adjust tensioner nut until flat washer |

|

|

|

| washer is flush with top of guide. |

Motor turns slowly | 1. | Contaminants | 1. | Remove large nut on side of large |

or not at all. |

| restricting spool |

| valve block. Remove spring, and use |

|

| movement in |

| needle nose vise grip to pull spool |

|

| valve body. |

| from block. Check block and spool |

|

|

|

| for contaminates and scratches. |

|

|

|

| Clean parts or replace if scratched. |

| 2. | Suction lines | 2. | Check for crimp or obstruction in |

|

| obstructed |

| suction hose |

| 3. | Low oil level | 3. | Check Hyd. tank level and fill |

Pump will not work | 1. | Excessive wear | 1. | Disassemble and repair. |

|

| on internal parts |

|

|

Side & Rear flail Maintenance Section