QUICK START

3

The Cover Retaining Knob holds the entire inking system together and other parts may fall free from the coder if not held securely when this knob is removed.

4

The Knurled Drive Wheel Cover is very loose fitting.

Note: The flat on the side of the Drive Wheel Cover is aligned towards the print drum. During reassembly, this must be replaced in the same position.

5

The Knurled Drive Wheel rests on top of the Transfer Roller and is installed over 3 stainless steel drive pins which pro- trude through 3 mating holes in the Drive Wheel.

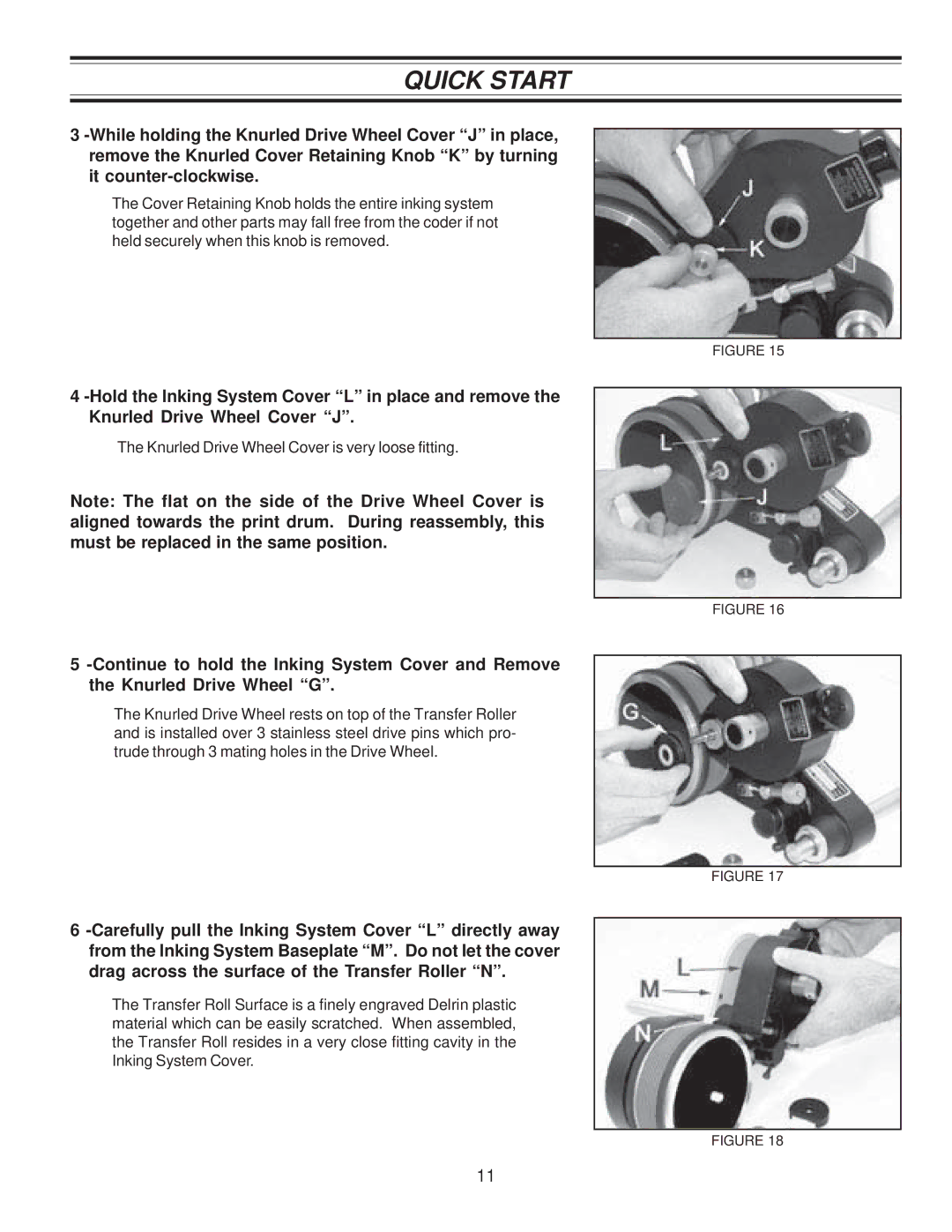

6

The Transfer Roll Surface is a finely engraved Delrin plastic material which can be easily scratched. When assembled, the Transfer Roll resides in a very close fitting cavity in the Inking System Cover.

FIGURE 15

FIGURE 16

FIGURE 17

FIGURE 18

11