BASIC PRINCIPLES OF OPERATION

INK DRYING TIME CONSIDERATIONS

Depending on the specific characteristics of the printing application, some consideration needs to be given to the drying time of the ink and its suitability for the application. Printing on a plastic film in an intermittent motion Form and Fill Machine may require a slower drying ink formulation than that recommended for high speed continuous web printing applications. Although extremely fast drying inks are normally specified by customers in all applica- tions, the ink must be suitable for the specific application or it will not perform properly in the coder.

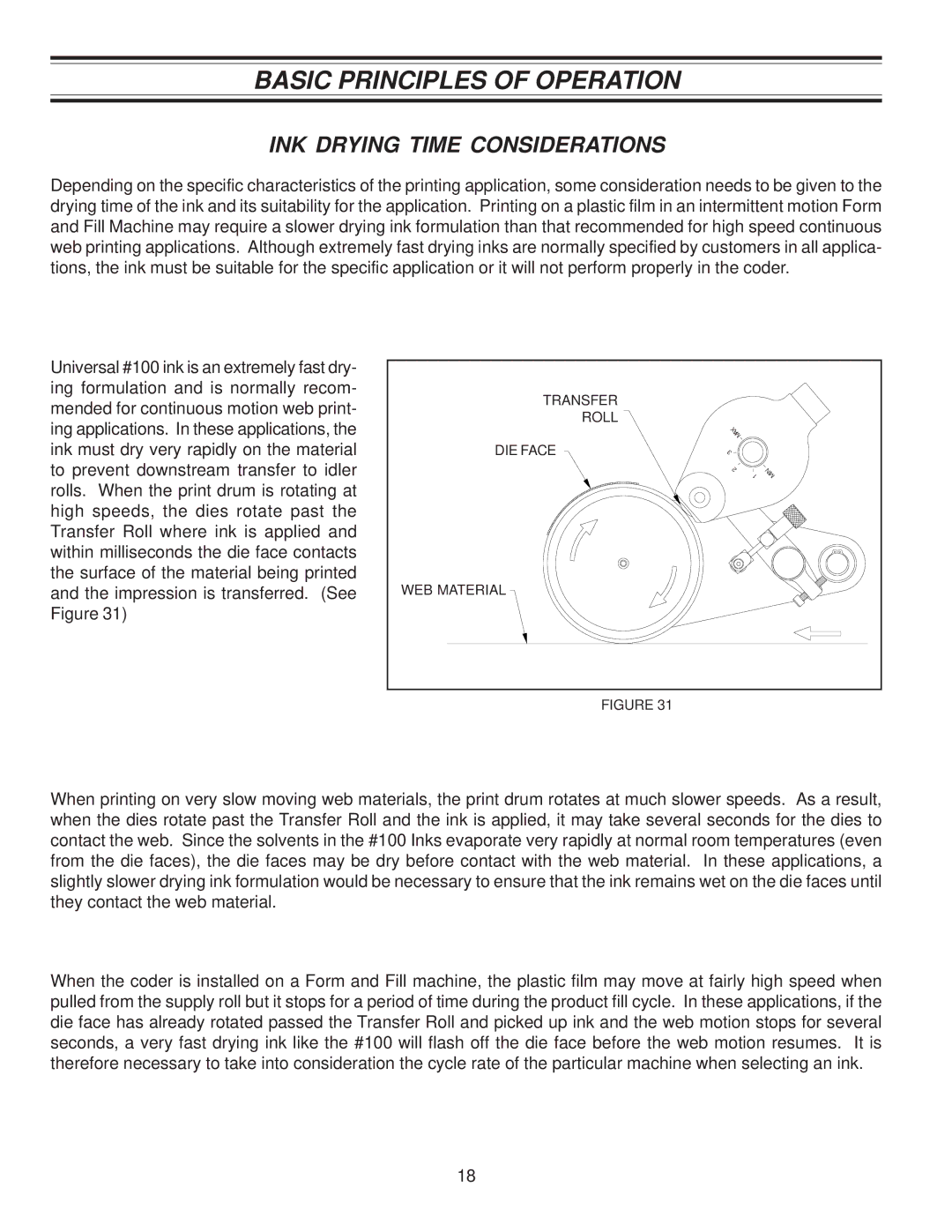

Universal #100 ink is an extremely fast dry- ing formulation and is normally recom- mended for continuous motion web print- ing applications. In these applications, the ink must dry very rapidly on the material to prevent downstream transfer to idler rolls. When the print drum is rotating at high speeds, the dies rotate past the Transfer Roll where ink is applied and within milliseconds the die face contacts the surface of the material being printed and the impression is transferred. (See Figure 31)

TRANSFER |

|

|

|

ROLL |

|

|

|

| MAX |

|

|

DIE FACE | 3 |

|

|

| 2 |

| MIN |

|

| 1 | |

|

|

| |

WEB MATERIAL |

|

|

|

FIGURE 31

When printing on very slow moving web materials, the print drum rotates at much slower speeds. As a result, when the dies rotate past the Transfer Roll and the ink is applied, it may take several seconds for the dies to contact the web. Since the solvents in the #100 Inks evaporate very rapidly at normal room temperatures (even from the die faces), the die faces may be dry before contact with the web material. In these applications, a slightly slower drying ink formulation would be necessary to ensure that the ink remains wet on the die faces until they contact the web material.

When the coder is installed on a Form and Fill machine, the plastic film may move at fairly high speed when pulled from the supply roll but it stops for a period of time during the product fill cycle. In these applications, if the die face has already rotated passed the Transfer Roll and picked up ink and the web motion stops for several seconds, a very fast drying ink like the #100 will flash off the die face before the web motion resumes. It is therefore necessary to take into consideration the cycle rate of the particular machine when selecting an ink.

18