MAINTENANCE

10

SET SCREW

POSITION

FOR RIGHT HAND MOUNT

SET SCREW

POSITION

FOR LEFT

HAND MOUNT

BOTTOM VIEW OF

INKING SYSTEM BASEPLATE

FIGURE 55

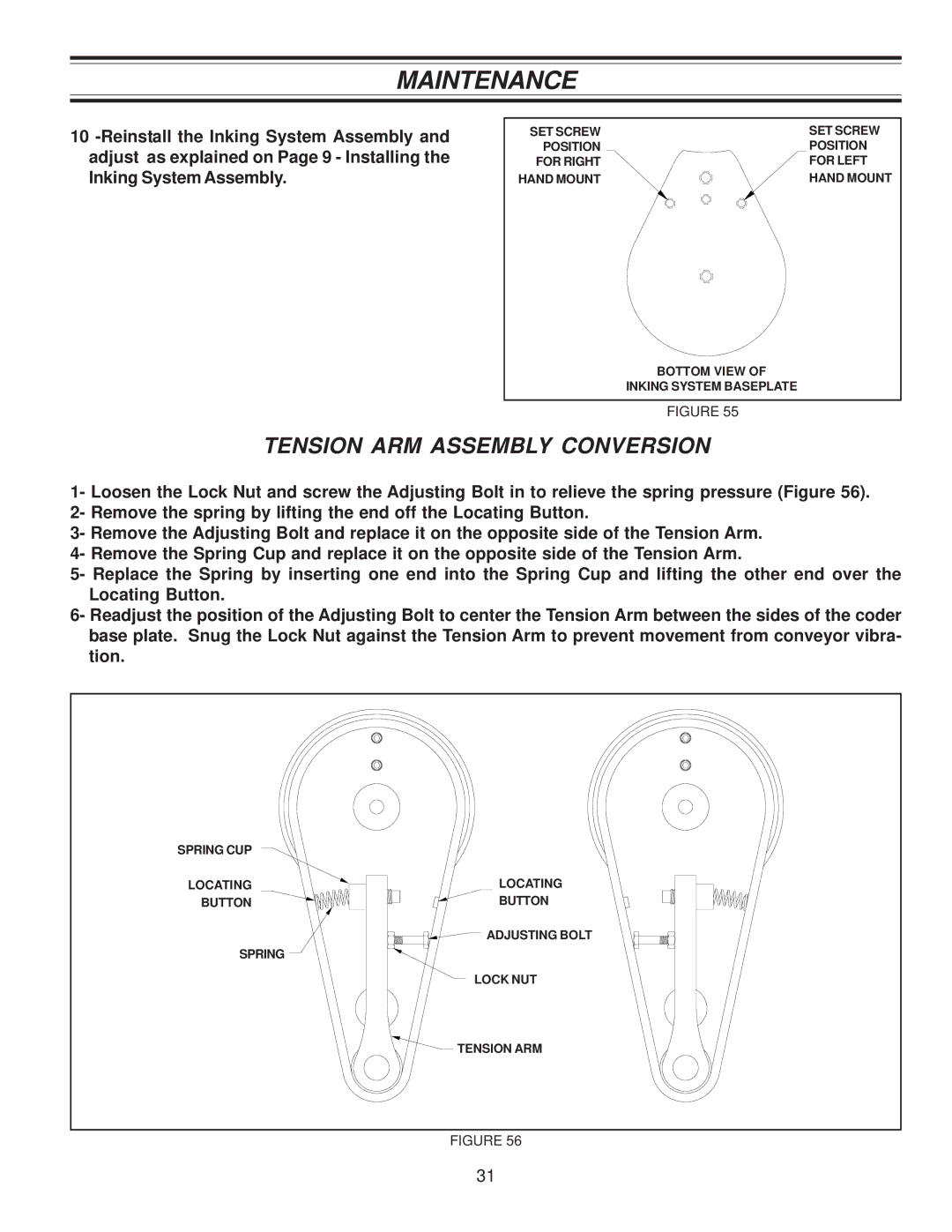

TENSION ARM ASSEMBLY CONVERSION

1- Loosen the Lock Nut and screw the Adjusting Bolt in to relieve the spring pressure (Figure 56).

2- Remove the spring by lifting the end off the Locating Button.

3- Remove the Adjusting Bolt and replace it on the opposite side of the Tension Arm.

4- Remove the Spring Cup and replace it on the opposite side of the Tension Arm.

5- Replace the Spring by inserting one end into the Spring Cup and lifting the other end over the Locating Button.

6- Readjust the position of the Adjusting Bolt to center the Tension Arm between the sides of the coder base plate. Snug the Lock Nut against the Tension Arm to prevent movement from conveyor vibra- tion.

SPRING CUP |

|

LOCATING | LOCATING |

BUTTON | BUTTON |

| ADJUSTING BOLT |

SPRING |

|

| LOCK NUT |

| TENSION ARM |

FIGURE 56

31