WEB PRINTING

DO NOT INSTALL A 4 oz. RESERVOIR INK CARTRIDGE AT THIS TIME. The coder is designed to print using the ink contained in the

SPECIAL WEB PRINTING APPLICATIONS

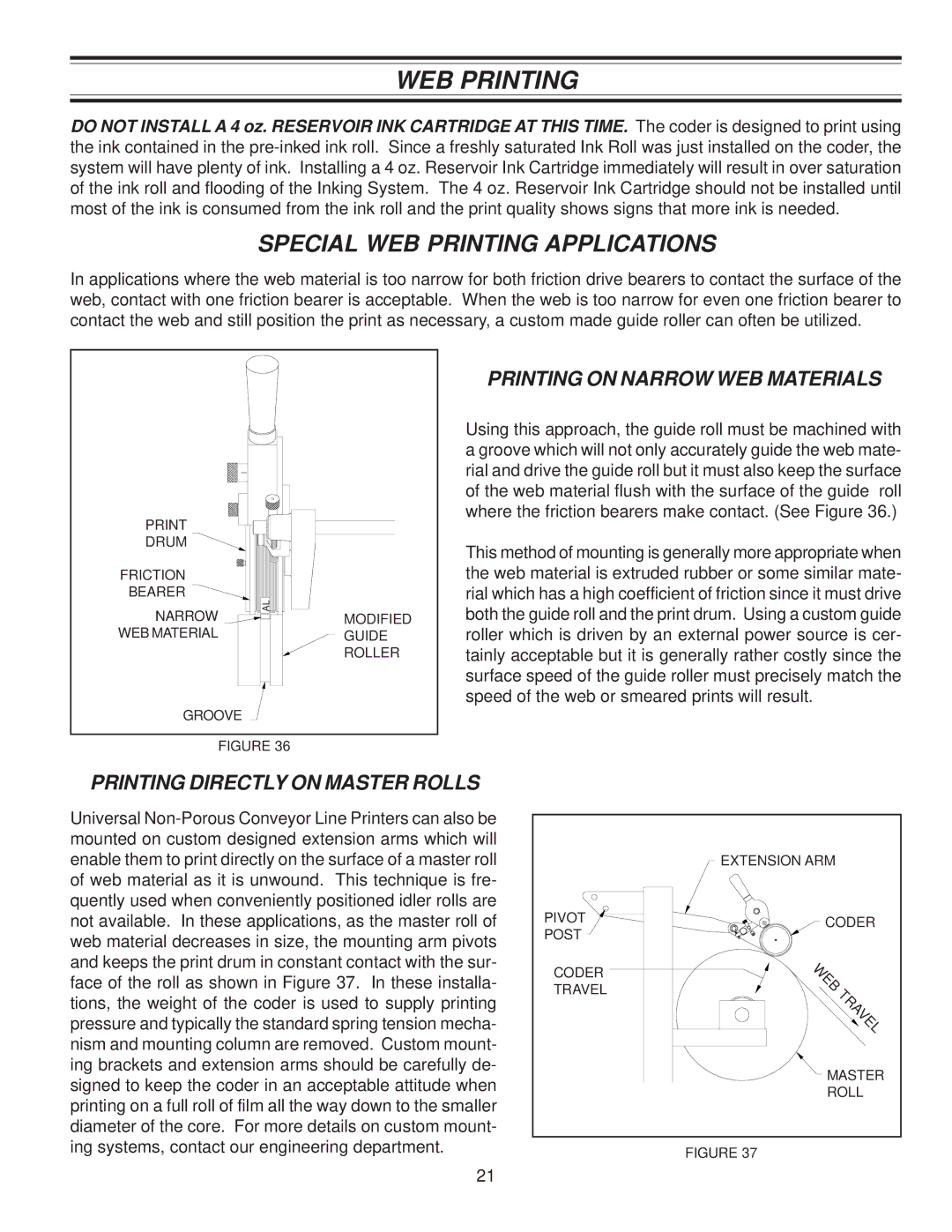

In applications where the web material is too narrow for both friction drive bearers to contact the surface of the web, contact with one friction bearer is acceptable. When the web is too narrow for even one friction bearer to contact the web and still position the print as necessary, a custom made guide roller can often be utilized.

DRUM

FRICTION

BEARER

NARROW | AL |

| |

WEB MATERIAL |

|

GROOVE

FIGURE 36

MODIFIED GUIDE ROLLER

PRINTING ON NARROW WEB MATERIALS

Using this approach, the guide roll must be machined with a groove which will not only accurately guide the web mate- rial and drive the guide roll but it must also keep the surface of the web material flush with the surface of the guide roll where the friction bearers make contact. (See Figure 36.)

This method of mounting is generally more appropriate when the web material is extruded rubber or some similar mate- rial which has a high coefficient of friction since it must drive both the guide roll and the print drum. Using a custom guide roller which is driven by an external power source is cer- tainly acceptable but it is generally rather costly since the surface speed of the guide roller must precisely match the speed of the web or smeared prints will result.

PRINTING DIRECTLY ON MASTER ROLLS

Universal

| EXTENSION ARM |

PIVOT | CODER |

POST |

|

CODER |

|

TRAVEL |

|

| MASTER |

| ROLL |

FIGURE 37

21