MAINTENANCE

CLEANING THE TRANSFER ROLL

The surface of the transfer roll is made from DuPont Delrin material and the O.D. of the roll is finely engraved which enables it to hold a uniform film of ink. This surface material is very fragile and under no circumstances should you attempt to clean it with anything abrasive.

Warning: Most of the ink solvents used for cleaning are flammable liquids. Follow all safety precau- tions recommended by the manufacturer during this process.

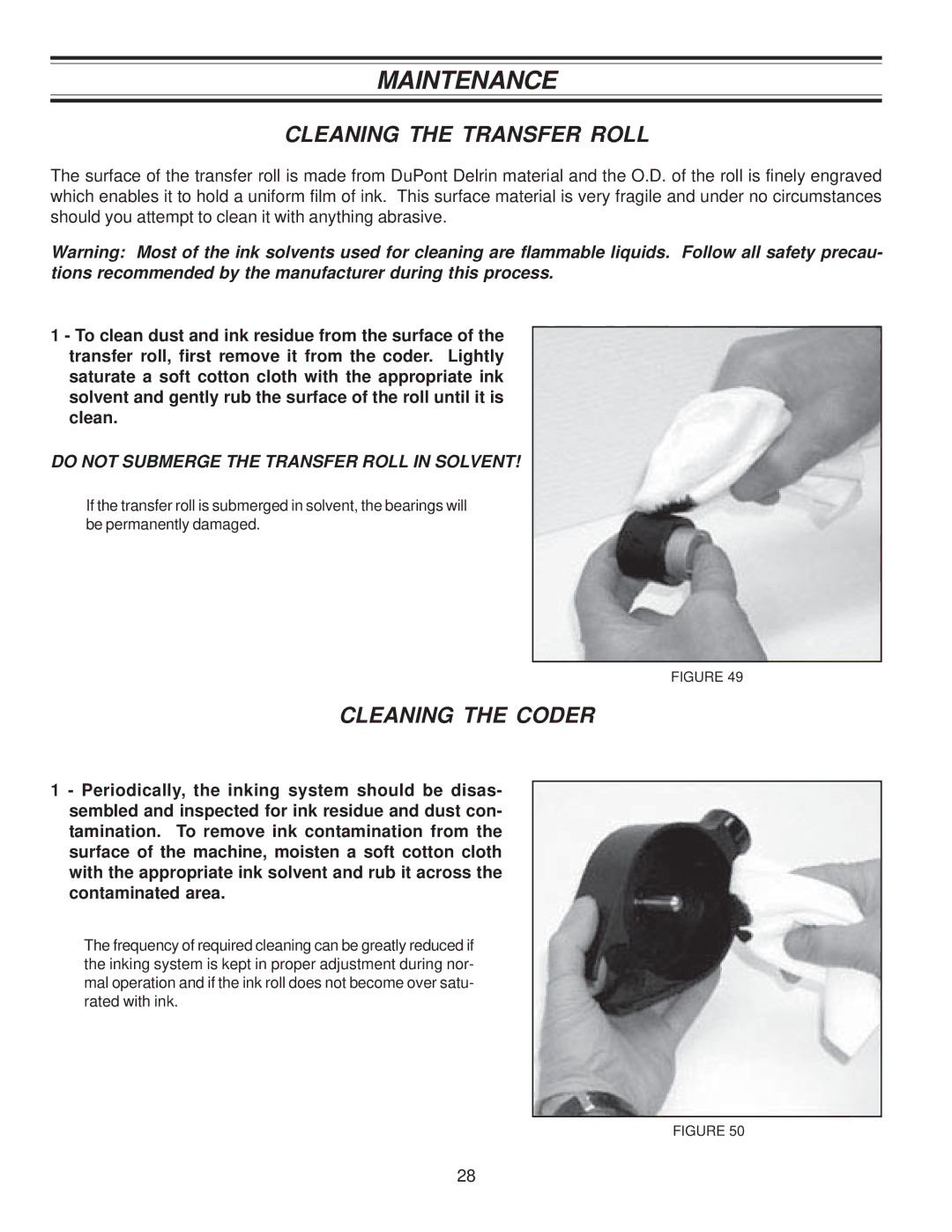

1 - To clean dust and ink residue from the surface of the transfer roll, first remove it from the coder. Lightly saturate a soft cotton cloth with the appropriate ink solvent and gently rub the surface of the roll until it is clean.

DO NOT SUBMERGE THE TRANSFER ROLL IN SOLVENT!

If the transfer roll is submerged in solvent, the bearings will be permanently damaged.

FIGURE 49

CLEANING THE CODER

1 - Periodically, the inking system should be disas- sembled and inspected for ink residue and dust con- tamination. To remove ink contamination from the surface of the machine, moisten a soft cotton cloth with the appropriate ink solvent and rub it across the contaminated area.

The frequency of required cleaning can be greatly reduced if the inking system is kept in proper adjustment during nor- mal operation and if the ink roll does not become over satu- rated with ink.

FIGURE 50

28